High-modulus bituminous mixture additive and preparation method thereof

An asphalt mixture and additive technology, which is applied in building thermal insulation materials, building components, buildings, etc., can solve the problems of high construction temperature and poor low temperature performance, improve rutting resistance, reduce mixing and compaction temperature, and improve processing. simple craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

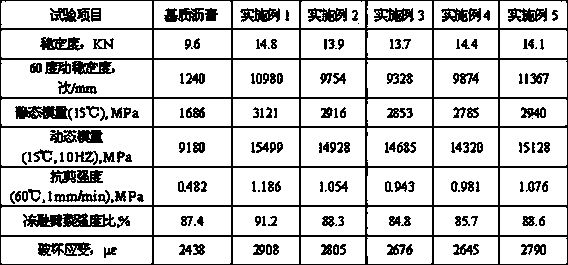

Examples

preparation example Construction

[0028] The preparation method of this high modulus asphalt mixture additive, carries out according to the following steps:

[0029] 1) Weigh the modified main agent, styrene-butadiene rubber, and polyethylene paraffin in proportion, heat up while stirring under the condition of 30-90r / m, and rapidly raise the temperature to 160-190°C to completely melt until the mixture is uniform;

[0030] 2) Add fillers, anti-aging components and plasticizing components to the melt, and stir at 150-300r / m for 15-30 minutes at 160-190°C to make the mixture evenly mixed;

[0031] 3) The mixture passes through the screw extruder to extrude the cylindrical semi-finished product, and then cools at room temperature, and the cooled semi-finished product is sent to the cutting machine for cutting, and the uniform granular finished product can be obtained.

Embodiment 1

[0033] A high-modulus asphalt mixture additive, which is composed of modified main agent, styrene-butadiene rubber, polyethylene paraffin, filler, anti-aging component, plasticizing component, etc. The mass percentage of each raw material is: modified main agent: Styrene butadiene rubber: polyethylene paraffin: filler: anti-aging component: plasticizing component = 100:15:20:50:5:12.

[0034] The modified main agent is a mixture of waste PE and polypropylene, and the mixing ratio is 80:20. The filler is diatomite, the anti-aging component is activated rubber powder, and the plasticizing component is dioctyl phthalate.

[0035] The preparation method of the above-mentioned high-modulus asphalt mixture additive is as follows: firstly, the modified main agent, styrene-butadiene rubber, and polyethylene paraffin are stirred at a low speed at 160-190°C, and mixed uniformly to form a melt; The aging component and the plasticizing component are added to the melt, the temperature is ...

Embodiment 2

[0037] A high-modulus asphalt mixture additive, which is composed of modified main agent, styrene-butadiene rubber, polyethylene paraffin, filler, anti-aging component, plasticizing component, etc. The mass percentage of each raw material is: modified main agent: Styrene butadiene rubber: polyethylene paraffin: filler: anti-aging component: plasticizing component = 100:20:25:55:4:12.

[0038] The modified main agent is a mixture of waste PE and polypropylene, and the mixing ratio is 75:25. The filler is organic bentonite, the anti-aging component is activated rubber powder, and the plasticizing component is dioctyl phthalate.

[0039] The preparation method of the high modulus asphalt mixture additive is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com