Admixing type modifier of asphalt mixture

A technology of asphalt mixture and modifier, which is applied in the direction of building insulation materials, building components, buildings, etc., can solve the problems of high product price and weak improvement effect of water stability performance, achieve low product cost, improve Marshall stability and High-temperature anti-rutting ability, effect of improving high-temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022]

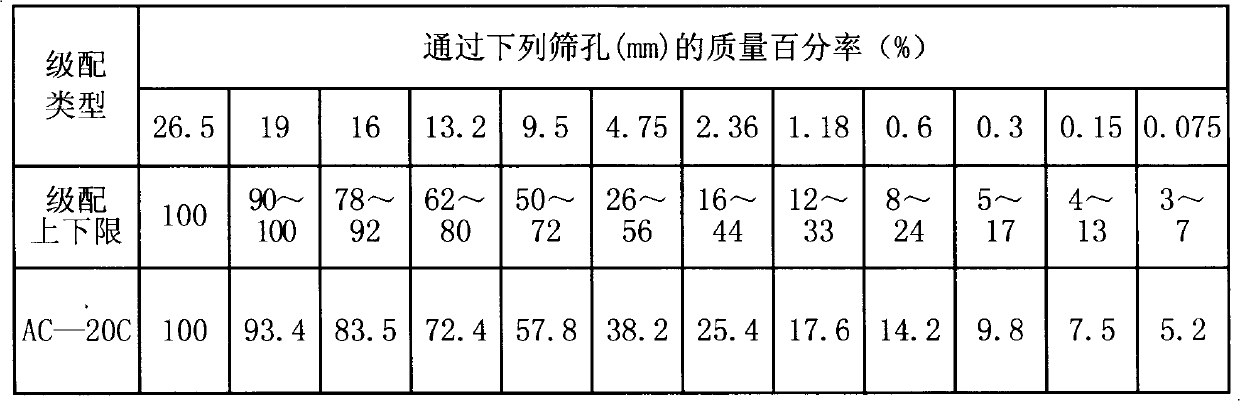

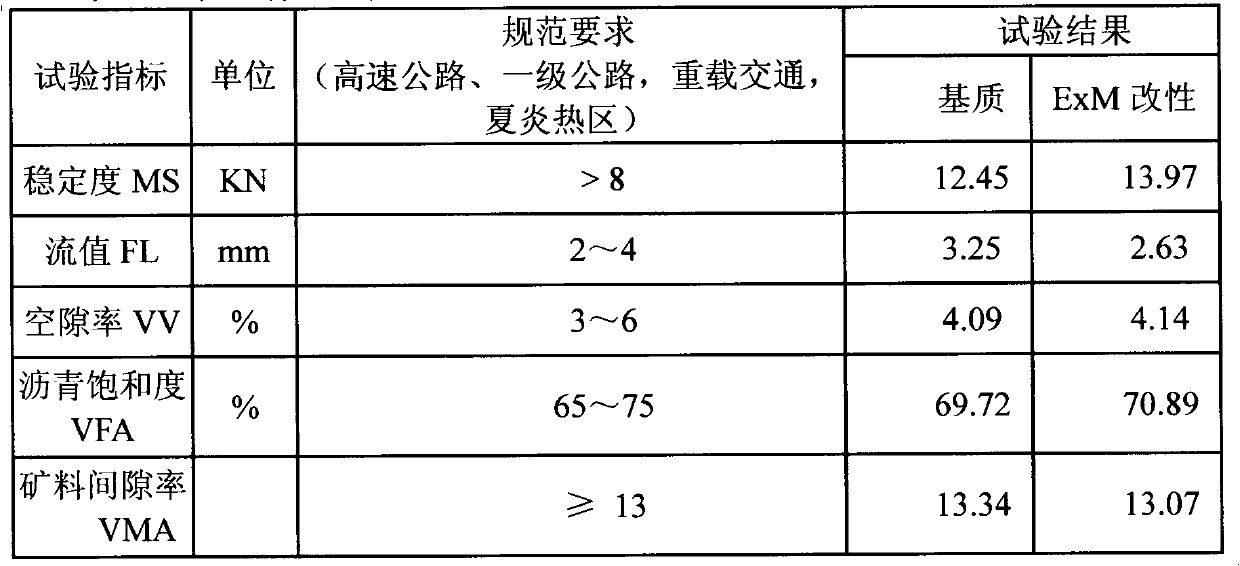

[0023] In order to verify the beneficial effect of the product of the present invention, the asphalt mixture externally mixed modifier prepared in this example was tested for road performance. The test method is as follows: first, dry mix the asphalt mixture with the externally-mixed modifier and the aggregate at a temperature of 175 °C for 10 seconds, then add the asphalt at a temperature of 150 °C determined by the viscosity-temperature curve, and add it after mixing for 120 seconds. Cold mineral powder, and finally mix for 60 seconds. The specific test materials and test methods are as follows:

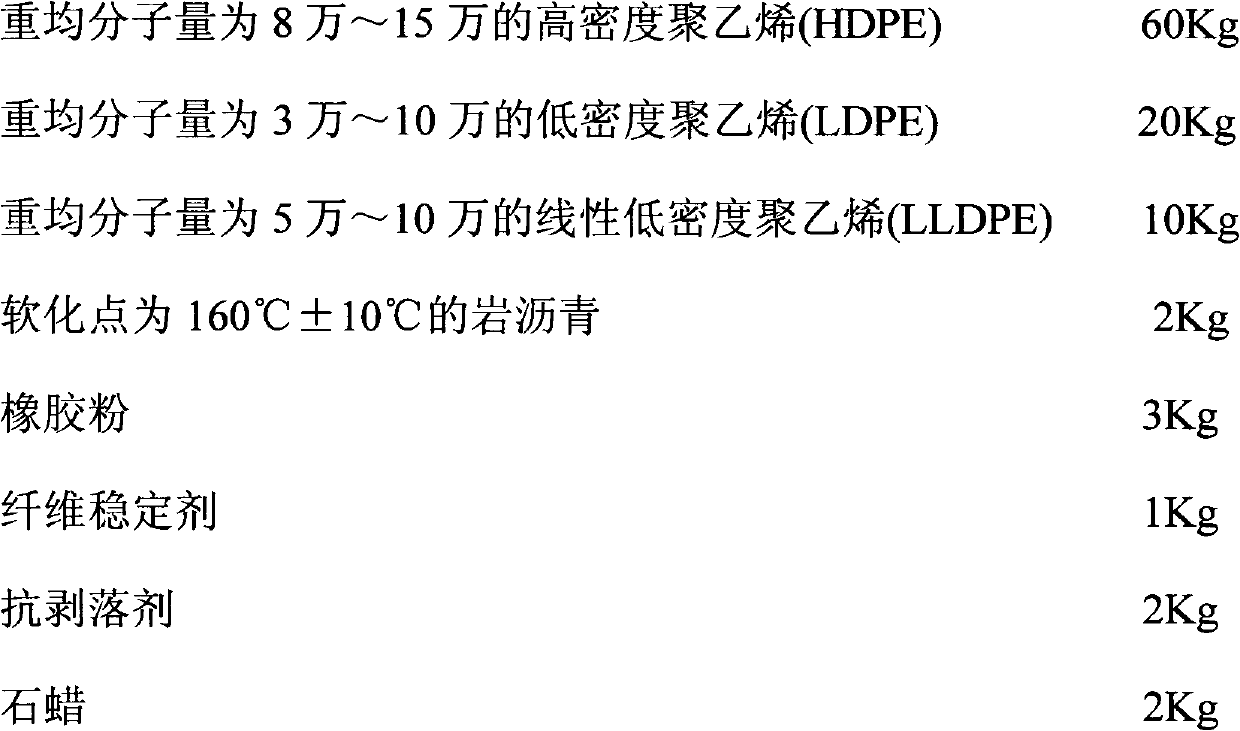

[0024] The asphalt used in the test is Guangdong Maoming Donghai brand 70# matrix asphalt, the aggregate is limestone, and the optimal oil-to-stone ratio is 4.4%; 0.4% of the mass of the asphalt mixture. In accordance with the requirements of "Technical Specification for Highway Asphalt Pavement Construction" (JTJ F40-2004), the properties of asphalt and aggregates ar...

Embodiment 2

[0090] The components and their mass percentages of the asphalt mixture external modifier are:

[0091]

[0092]

[0093] Its preparation method is identical with embodiment 1.

Embodiment 3

[0095] The components and their mass percentages of the asphalt mixture external modifier are:

[0096]

[0097] Its preparation method is identical with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com