Modified asphalt viscosity decreasing agent

A technology of modified asphalt and viscosity reducer, which is applied in the direction of building components, building insulation materials, buildings, etc. It can solve the problems of reduced compaction time, damage to the mixture, and low flatness, so as to improve high temperature stability and reduce high temperature. Viscosity, formula simple and practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with embodiment further illustrate the present invention.

[0019] Adopt the ratio of the following table to carry out the implementation of the viscosity reducer

[0020] components

Weight g

p-Hydroxyphenylglycine

5000

Sorbitan Tristearate

1000

Synthetic aliphatic hydrocarbons at 90-140°C

8000

1000

[0021] Process: Dehydrate castor oil at 100-120°C, add p-hydroxyphenylglycine, sorbitan tristearate and synthetic aliphatic hydrocarbons at 90-140°C, and extrude in a screw extruder at a temperature of 80-100°C Blending, extrusion, granulation and cooling.

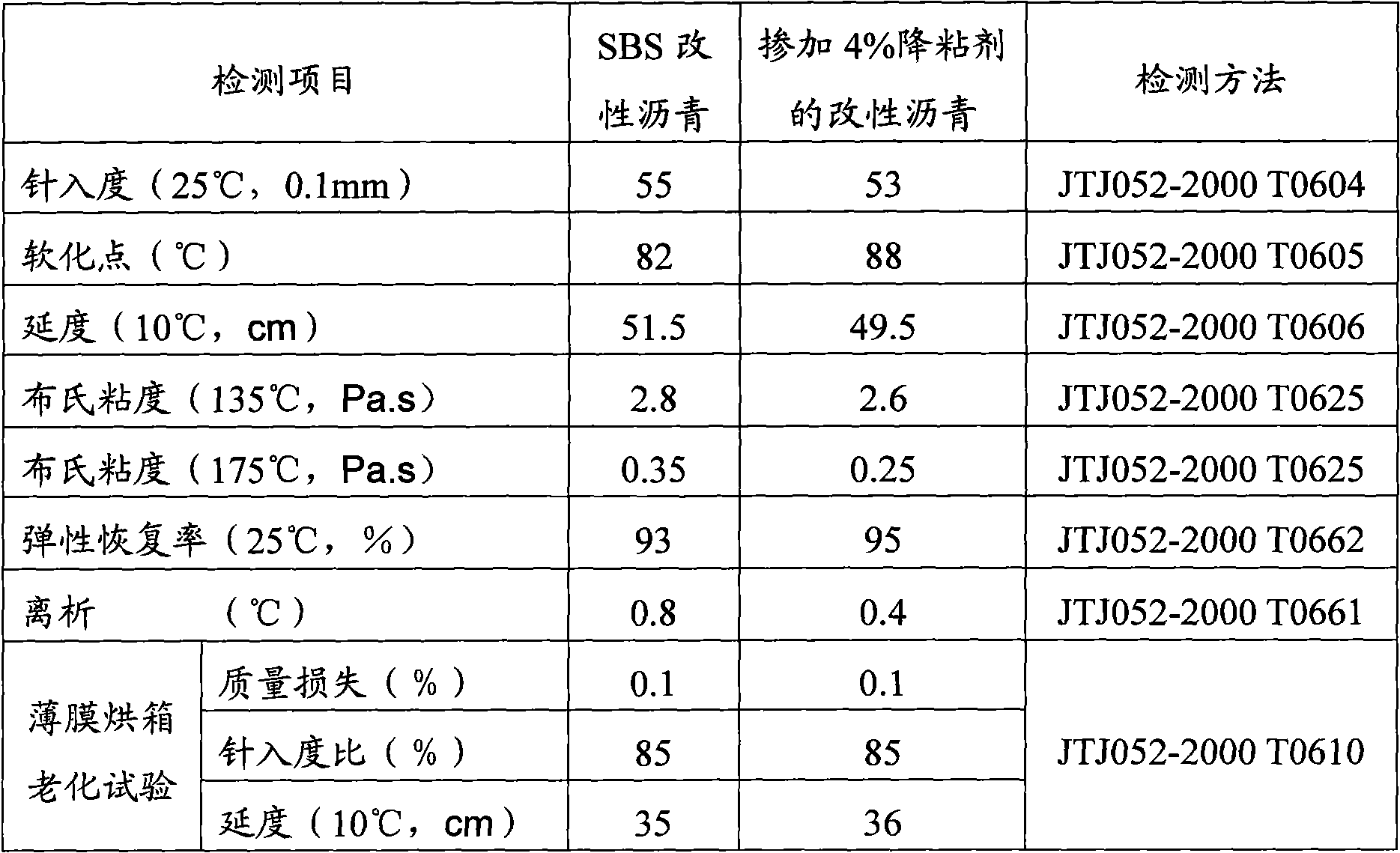

[0022] The effect of modified asphalt viscosity reducer on the performance of SBS modified asphalt is as follows:

[0023]

[0024] The effect of modified asphalt viscosity reducer on the performance of cast asphalt concrete GA10 is as follows:

[0025]

Pilot projects

Poured with 4% viscosity r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com