Asphalt pavement structure suitable for Tibet plateau area and construction method thereof

A kind of asphalt pavement and regional technology, applied in the field of road engineering construction, can solve the problems of short service life, serious early disease, frequent maintenance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

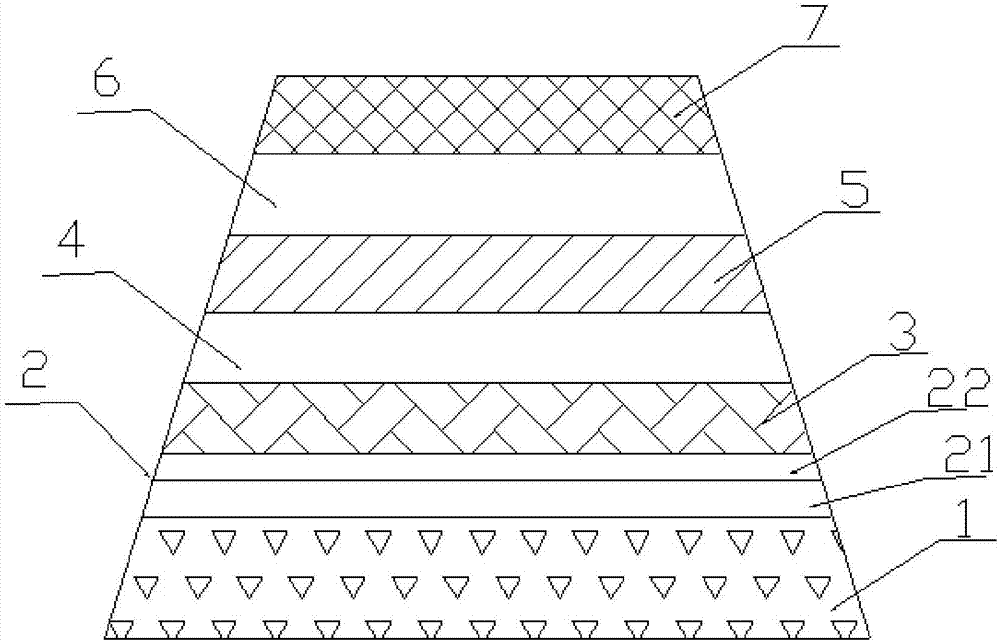

[0047] Such as figure 1 As shown, an asphalt pavement structure suitable for the Qinghai-Tibet Plateau area includes, from bottom to top, cushion layer 1, semi-rigid base layer 2, permeable layer 3, SBR emulsified asphalt lower seal layer 4, lower layer 5, adhesive layer 6 and upper layer Layer 7.

[0048] Further, the cushion layer 1 is a natural gravel layer, and the thickness of the cushion layer 1 is 30 cm.

[0049] Further, the semi-rigid base layer 2 includes an upper base layer 22 and a lower base layer 21,

[0050] The upper base 22 is a low-shrinkage ultra-early-strength cement stabilized gravel layer,

[0051] The base course 21 is a cement-stabilized gravel layer,

[0052] The gradation types of the upper base layer 22 and the lower base layer 21 are both skeleton dense structures,

[0053] The thickness of the base layer 21 is 16cm,

[0054] The upper base layer 22 has a thickness of 16 cm.

[0055] Further, the permeable layer 3 is an SBR modified emulsified a...

specific Embodiment 2

[0073] An asphalt pavement structure suitable for the Qinghai-Tibet Plateau region, comprising a cushion layer 1, a semi-rigid base layer 2, a permeable layer 3, an SBR emulsified asphalt lower seal layer 4, a lower layer 5, an adhesive layer 6 and an upper layer 7 from bottom to top.

[0074] Further, the cushion layer 1 is a natural gravel layer, and the thickness of the cushion layer 1 is 50 cm.

[0075] Further, the semi-rigid base layer 2 includes an upper base layer 22 and a lower base layer 21,

[0076] The upper base 22 is a low-shrinkage ultra-early-strength cement stabilized gravel layer,

[0077] The base course 21 is a cement-stabilized gravel layer,

[0078] The gradation types of the upper base layer 22 and the lower base layer 21 are both skeleton dense structures,

[0079] The thickness of the base layer 21 is 20cm,

[0080] The thickness of the upper base layer 22 is 20 cm.

[0081] Further, the permeable layer 3 is an SBR modified emulsified asphalt layer...

specific Embodiment 3

[0099] An asphalt pavement structure suitable for the Qinghai-Tibet Plateau region, comprising a cushion layer 1, a semi-rigid base layer 2, a permeable layer 3, an SBR emulsified asphalt lower seal layer 4, a lower layer 5, an adhesive layer 6 and an upper layer 7 from bottom to top.

[0100] Further, the cushion layer 1 is a natural gravel layer, and the thickness of the cushion layer 1 is 40 cm.

[0101] Further, the semi-rigid base layer 2 includes an upper base layer 22 and a lower base layer 21,

[0102] The upper base 22 is a low-shrinkage ultra-early-strength cement stabilized gravel layer,

[0103] The base course 21 is a cement-stabilized gravel layer,

[0104] The gradation types of the upper base layer 22 and the lower base layer 21 are both skeleton dense structures,

[0105] The thickness of the base layer 21 is 18cm,

[0106] The upper base layer 22 has a thickness of 18 cm.

[0107] Further, the permeable layer 3 is an SBR modified emulsified asphalt layer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com