High-grade road asphalt prepared from coal tar pitch

A technology for road asphalt and coal tar, which is applied in building components, building insulation materials, buildings, etc., can solve problems such as single modifier, lack of general attention, stability problems, etc., and achieve high temperature stability and penetration. The effect of decreasing and increasing the stability value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] A high-grade road asphalt prepared from coal tar pitch, consisting of the following raw materials in parts by weight:

[0052] 30 parts of coal tar pitch

[0053] 15 parts petroleum pitch

[0054] Solvent oil: 30 parts of rubber solvent oil

[0055] Composite polymer additive 3 parts

[0056] Antiaging agent: 2 parts of N-phenyl-N`-isopropyl-p-phenylenediamine

[0057] Cross-linking agent: 0.3 parts of p-tolualdehyde.

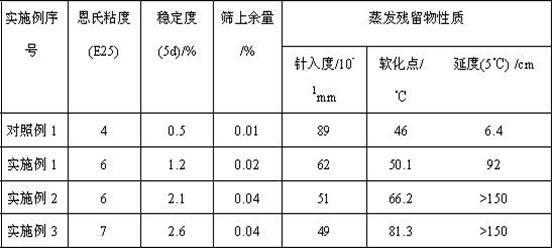

[0058] According to the above ratio of raw materials, after dehydration, add solvent oil and mix 0.5 evenly, then add a composite polymer composed of 2 parts of waste rubber powder, 3 parts of regenerated rubber powder, 2 parts of polyvinyl chloride, and 4 parts of neoprene rubber The additive, anti-aging agent and cross-linking agent were reacted for 5 hours at a reaction temperature of 250°C, and the reaction was continued for 1 hour after cooling down to 120°C to obtain high-grade road asphalt. The specific performance indicators are shown in Exa...

Embodiment 2

[0060] A high-grade road asphalt prepared from coal tar pitch, consisting of the following raw materials in parts by weight:

[0061] 70 parts of coal tar pitch

[0062] 30 parts petroleum asphalt

[0063] Solvent oil: 50 parts of rubber solvent oil

[0064] Composite polymer additive 5 parts

[0065] Antiaging agent: 10 parts of N-phenyl-N`-isopropyl-p-phenylenediamine

[0066] Cross-linking agent: 0.5 parts of p-tolualdehyde.

[0067] According to the above ratio of raw materials, coal tar pitch is dehydrated, added solvent oil and mixed evenly for 1 hour, and then added a composite polymer consisting of 3 parts of waste rubber powder, 5 parts of recycled rubber powder, 5 parts of polyvinyl chloride, and 5 parts of neoprene rubber Additives, antioxidants and cross-linking agents react for 5 hours. The reaction temperature is 260°C. After cooling down to 120°C and adding polyvinyl chloride, the reaction is continued for one hour to obtain high-grade road asphalt. The sp...

Embodiment 3

[0069] A high-grade road asphalt prepared from coal tar pitch, consisting of the following raw materials in parts by weight:

[0070] 50 parts of coal tar pitch

[0071] 25 parts petroleum pitch

[0072] Solvent oil: 40 parts of rubber solvent oil

[0073] Composite polymer additive 4 parts

[0074] Antiaging agent: 5 parts of N-phenyl-N`-isopropyl-p-phenylenediamine

[0075] Cross-linking agent: 0.4 parts of p-tolualdehyde.

[0076] According to the above ratio of raw materials, coal tar pitch is dehydrated, then added solvent oil and mixed evenly for 0.8h, then added a composite polymer composed of 2 parts of waste rubber powder, 4 parts of regenerated rubber powder, 3 parts of polyvinyl chloride, and 4 parts of neoprene rubber Additives, antioxidants and cross-linking agents react for 5 hours. The reaction temperature is 250° C., and the reaction is continued for 1 hour after cooling down to 120° C. to obtain high-grade road asphalt. The specific performance index is sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com