Environment-friendly asphalt pavement anti-rut agent and preparation method thereof

A technology of asphalt pavement and anti-rutting agent, which is applied to building insulation materials, building components, buildings, etc. It can solve problems such as unreasonable pavement design, thin pavement thickness, and large traffic volume, so as to increase market competitiveness and reduce rutting , the effect of protecting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

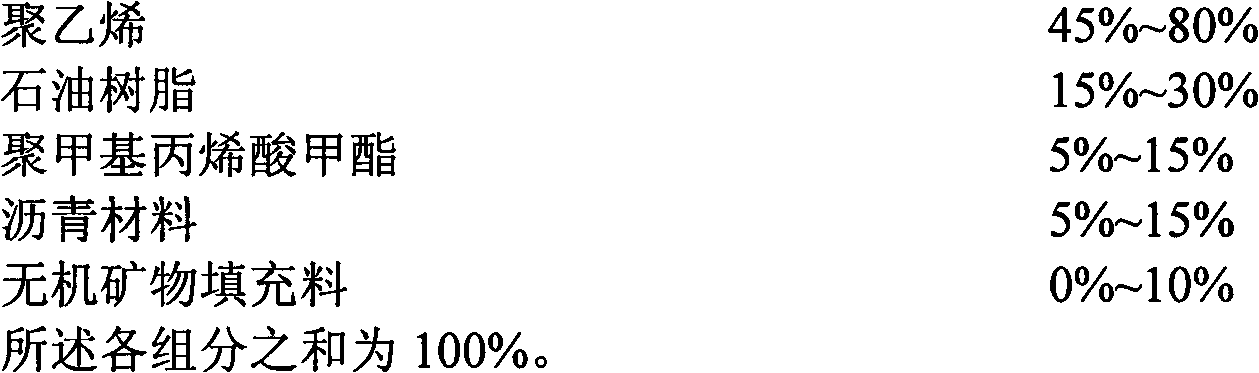

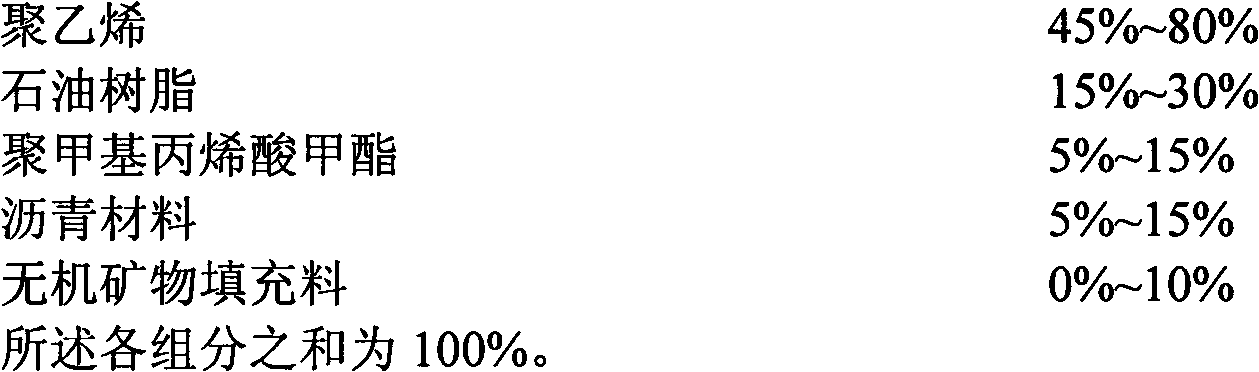

Method used

Image

Examples

Embodiment 1

[0025] Add 45% polyethylene, 20% petroleum resin, and 20% natural asphalt to the high-speed mixer, adjust the speed of the mixer to 1800-2000 rpm, and raise the temperature to 140-150°C for 0.5 hours, and add 5% polyformaldehyde Methyl acrylate and 10% glass hollow microspheres, adjust the speed of the mixer to 8000-10000 rpm, stir at high speed for 1-1.5 hours, and heat up to 150-170 ° C; put the mixed material into twin-screw extrusion Machine, keep 150-170 ℃, make it form a molten mixture and then extrude; maintain 130-150 ℃ environment in the water cooling process, and cut into pellets to obtain the finished product.

Embodiment 2

[0027] Add 50% polyethylene, 25% petroleum resin, and 13% natural asphalt to the high-speed mixer, adjust the speed of the mixer at 1800-2000 rpm and raise the temperature to 140-150°C for 0.5 hours, and add 8% polyformaldehyde Methyl acrylate and 4% glass hollow microspheres, adjust the speed of the mixer to 8000-10000 rpm, stir at high speed for 1-1.5 hours, and heat up to 150-170 °C; put the mixed material into twin-screw extrusion Machine, keep 150-170 ℃, make it form a molten mixture and then extrude; maintain 130-150 ℃ environment in the water cooling process, and cut into pellets to obtain the finished product.

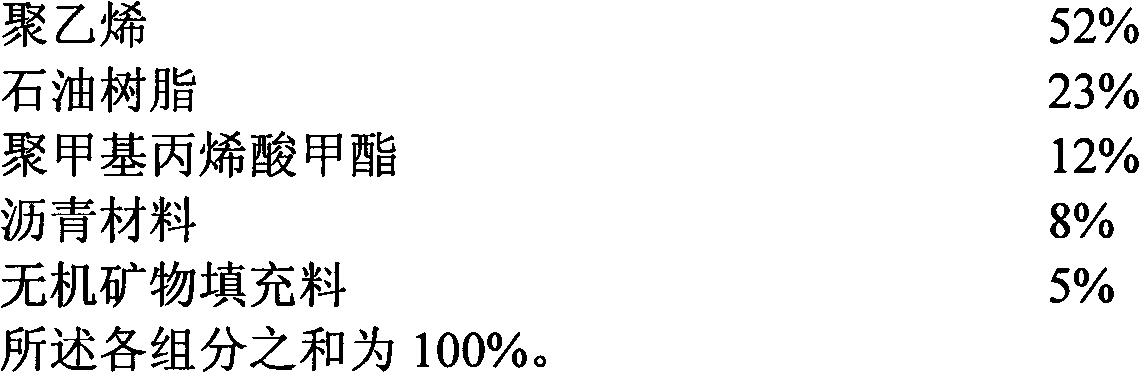

Embodiment 3

[0029] Add 60% polyethylene, 10% petroleum resin, and 13% natural asphalt to the high-speed mixer, adjust the speed of the mixer at 1800-2000 rpm and raise the temperature to 140-150°C for 0.5 hours, and add 12% polyformaldehyde Methyl acrylate and 5% glass hollow microspheres, adjust the speed of the mixer to 8000-10000 rpm, stir at high speed for 1-1.5 hours, and heat up to 150-170 °C; put the mixed material into twin-screw extrusion Machine, keep 150-170 ℃, make it form a molten mixture and then extrude; maintain 130-150 ℃ environment in the water cooling process, and cut into pellets to obtain the finished product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com