Waste superpolymer based comprehensive asphaltic-mixture modifier and preparation method and application thereof

A technology of asphalt mixture and modifier, applied in building structure, building thermal insulation material, building components and other directions, can solve the problems of complex formula components and synthesis process, low cost performance, unfavorable low temperature performance, etc., and achieve social benefits And the environmental benefits are significant, the promotion and application prospects are broad, and the effect of reducing the application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

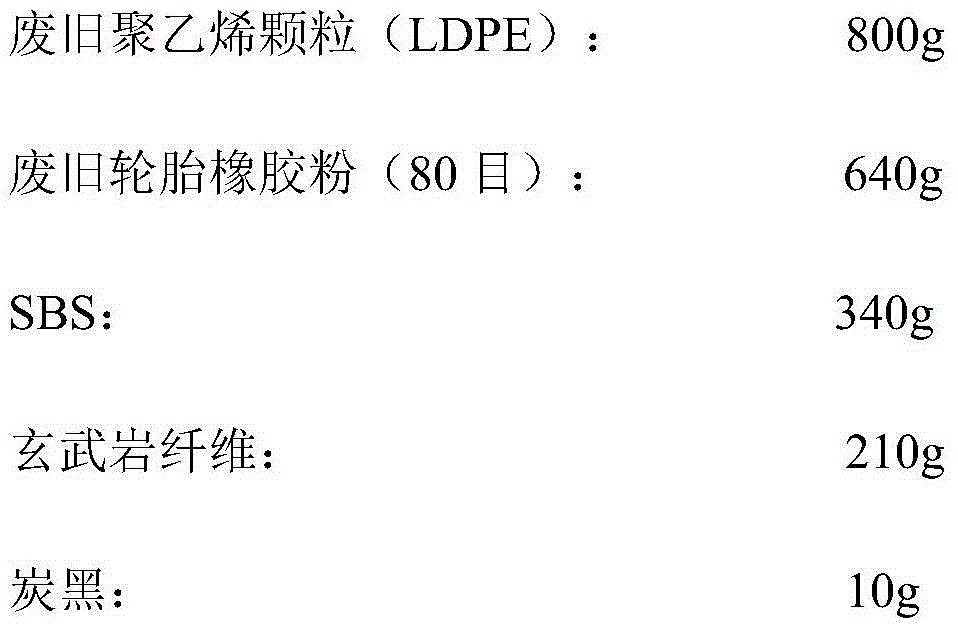

[0027] The raw material that this example adopts and the parts by weight of each component are:

[0028]

[0029] Take laboratory production 2000g of product of the present invention as example, the required weight of each raw material is as follows:

[0030]

[0031] The preparation method is as follows:

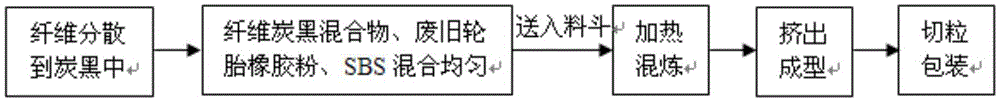

[0032] Pre-mix the weighed fiber and carbon black, use a disperser to mix the two evenly, and then mix them with waste polyethylene particles, waste tire rubber powder, and SBS evenly, and send them into the hopper of the twin-screw extruder; open the double-screw extruder For screw extrusion, set the temperature of each zone. The heating temperature of the first zone is 110°C, the second zone is 135°C, the third zone is 160°C, the fourth zone is 180°C, and the temperature of the head is 170°C. The rotation speed is set at 40 rpm; after heating to the set temperature, the valve of the hopper is opened, and the mixture is conveyed, mixed, melted, kneaded, extruded int...

Embodiment 2

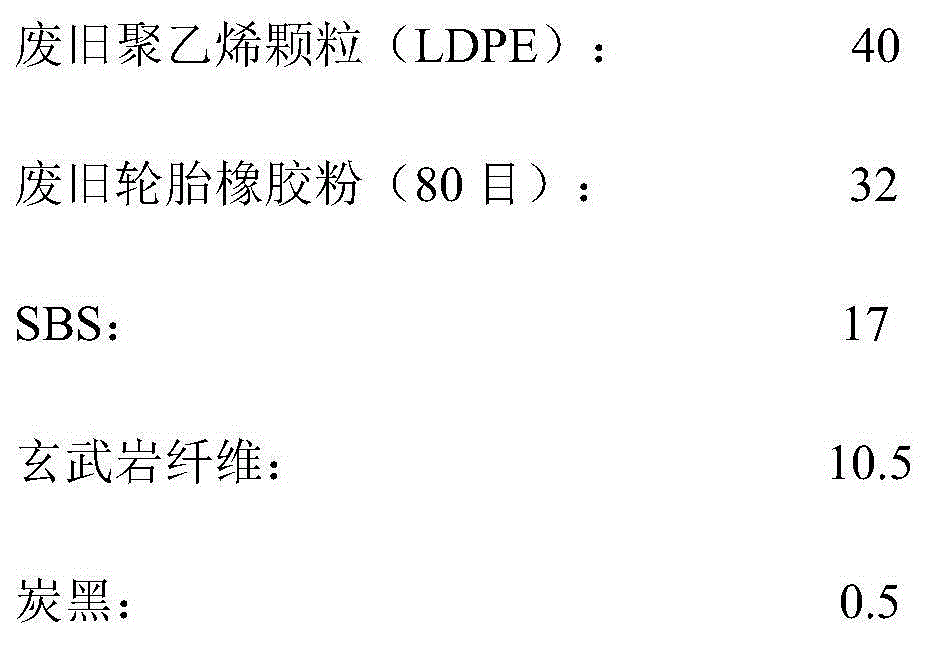

[0038] The raw material that this example adopts and the parts by weight of each component are:

[0039]

[0040] Taking the production of 10kg of the product of the present invention as an example, the required weight of each raw material is as follows:

[0041]

[0042] The preparation method is as follows:

[0043] Pre-mix the weighed lignin fiber and carbon black, use a disperser to mix the two evenly, and then mix with waste polyethylene particles, waste tire rubber powder, and SBS evenly, and send them into the hopper of the twin-screw extruder; Turn on the twin-screw extrusion, set the temperature of each zone, the heating temperature of the first zone is 110°C, the second zone is 140°C, the third zone is 170°C, the fourth zone is 185°C, the head temperature is 175°C, extrude The speed of the machine is set at 50 rpm; after heating to the set temperature, the valve of the hopper is opened, and the mixture is conveyed, mixed, melted, kneaded, extruded into a rope-sh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com