Rubber powder modified asphalt and preparation method thereof

A technology for modifying asphalt and rubber powder, which is applied in building components, building insulation materials, buildings, etc., which can solve the problems of difficult asphalt construction and poor stability, and achieve reduced construction difficulty, increased stability, and increased softening degree Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

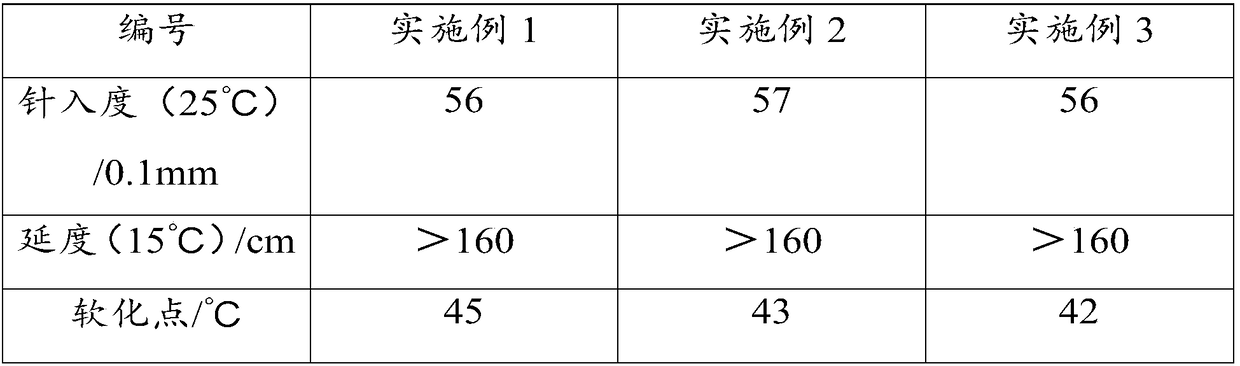

Examples

preparation example Construction

[0029] The embodiment of the present invention also provides a kind of preparation method of rubber powder modified asphalt, it comprises:

[0030] S1: Heat rock asphalt to 170-210°C, add rubber powder and stir at a stirring speed of 2000-3000r / min to obtain the first mixture; heat rock asphalt to a high temperature state, so that the rheology of rock asphalt is enhanced. The machinability is improved.

[0031] S2: The first mixture is sheared at a shear rate of 4500-5000r / min for 45-50min, and after adding stabilizer, SBS modifier and PE modifier, it is obtained after stirring and developing at 170-200°C the second mixture;

[0032] S3: adding polyphosphoric acid to the second mixture and stirring at a speed of 500-600 r / min for 30-40 minutes to obtain the third mixture;

[0033] S4: add the third mixture to the solubilizer and aromatic oil, swell at a temperature of 170-200° C. for 40-50 minutes, and then continue to shear at a shear rate of 4500-5000 r / min for 45-50 minut...

Embodiment 1

[0045] This embodiment provides a rubber-modified asphalt, which is mainly prepared by the following method:

[0046] S1: 30 parts by weight of rock asphalt were heated to 170°C, then added to 10 parts of rubber powder, and stirred at a stirring speed of 2000r / min to obtain the first mixture;

[0047] Wherein, step S1 specifically includes:

[0048] S11: Pulverize rock asphalt and rubber powder to 30 meshes and set aside;

[0049] S12: heating the pulverized rock asphalt to 170° C., adding pulverized rubber powder and stirring at a stirring speed of 2000 r / min to obtain a first mixture.

[0050] S2: The first mixture was sheared at a shear rate of 4500r / min for 45min, and after adding 2 parts of stabilizer, 1 part of SBS modifier and 1 part of PE modifier in parts by weight, the Stirring at a speed of 2000r / min for 30min under the condition of 170°C to obtain the second mixture;

[0051] S3: Add 20 parts by weight of polyphosphoric acid to the second mixture and stir at a s...

Embodiment 2

[0057] This embodiment provides a rubber-modified asphalt, which is mainly prepared by the following method:

[0058] S1: 35 parts by weight of rock asphalt were heated to 190°C, then added to 25 parts of rubber powder, and stirred at a stirring speed of 2500r / min to obtain the first mixture;

[0059] Wherein, step S1 specifically includes:

[0060] S11: pulverize rock asphalt and rubber powder to 50 meshes and set aside;

[0061] S12: heating the pulverized rock asphalt to 190° C., adding pulverized rubber powder and stirring at a stirring speed of 2000-3000 r / min to obtain a first mixture.

[0062] S2: The first mixture was sheared at a shear rate of 4800r / min for 48min, and after adding 2.5 parts of stabilizer, 3 parts of SBS modifier and 1.5 parts of PE modifier in parts by weight, the Stirring at a speed of 2500 r / min for 35 minutes under the condition of 190 ° C to obtain the second mixture;

[0063] S3: Add 25 parts by weight of polyphosphoric acid to the second mixt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com