Waste polymer compound asphalt anti-rutting agent as well as preparation method and application thereof

A technology of composite asphalt and anti-rutting agent, which is applied in building structures, building components, building thermal insulation materials, etc., can solve the problems of inability to uniformly disperse and poor compatibility, and achieves improved high temperature performance and anti-rutting performance. performance, the effect of reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

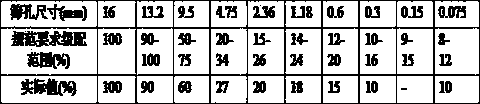

Image

Examples

Embodiment 1

[0039] 1) The parts by weight of the components of the anti-rutting additive are as follows:

[0040] Waste non-PVC multi-layer co-extrusion film scrap 77kg

[0041] Recycled polytetrafluoroethylene particles (100 mesh) 5kg

[0042] Waste tire rubber powder (80 mesh) 7kg

[0043] Compatibilizer 1kg

[0044] Asphalt 10kg

[0045] 2) Preparation method of anti-rutting additive:

[0046] a. Knead the waste non-PVC multi-layer co-extruded film scraps, recycled polytetrafluoroethylene particles, waste tire rubber powder, and compatibilizer in a high-speed kneader at room temperature for 5 minutes at a speed of 800 rpm.

[0047] b. Heat the asphalt at 180° C. for 5 minutes, and the stirring speed is 60 rpm.

[0048] c. Put the mixture in step a into the asphalt in step b and stir for 1 hour, the temperature is maintained at 180° C., and the stirring speed is 100 rpm.

[0049] d. The mixture in step c is extruded through a twin-screw extruder, sheared and granulated to obtain t...

Embodiment 2

[0051] 1) The parts by weight of the components of the anti-rutting additive are as follows:

[0052] Waste non-PVC multi-layer co-extrusion film scrap 50kg

[0053] Recycled polytetrafluoroethylene particles (100 mesh) 25kg

[0054] Waste tire rubber powder (40 mesh) 9.5kg

[0055] Compatibilizer 0.5kg

[0056] Asphalt 15kg

[0057] 2) Preparation method of anti-rutting additive:

[0058] a. Knead the waste non-PVC multi-layer co-extruded film scraps, recycled polytetrafluoroethylene particles, waste tire rubber powder, and compatibilizer in a high-speed kneader at room temperature for 10 minutes at a speed of 500 rpm.

[0059]b. Heat the asphalt at 190° C. for 5 minutes, and the stirring speed is 100 rpm.

[0060] c. Put the mixture in step a into the bitumen in step b and stir for 1.5 h, the temperature is maintained at 190° C., and the stirring speed is 150 rpm.

[0061] d. extruding the mixture in step c through a single-screw extruder, shearing and granulating to o...

Embodiment 3

[0063] 1) The parts by weight of the components of the anti-rutting additive are as follows:

[0064] Waste non-PVC multi-layer co-extrusion film scrap 60kg

[0065] Recycled polytetrafluoroethylene particles (150 mesh) 12kg

[0066] Waste tire rubber powder (60 mesh) 10kg

[0067] Compatibilizer 0.6kg

[0068] Asphalt 17.4kg

[0069] 2) Preparation method of anti-rutting additive:

[0070] a. Knead the above waste non-PVC multi-layer co-extrusion film scraps, recycled polytetrafluoroethylene particles, waste tire rubber powder, and compatibilizer in a high-speed kneader at room temperature for 10 minutes at a speed of 900 rpm.

[0071] b. Heat the asphalt at 180° C. for 9 minutes, and the stirring speed is 110 rpm.

[0072] c. Put the mixture in step a into the bitumen in step b and stir for 1 hour, the temperature is maintained at 180° C., and the stirring speed is 120 rpm.

[0073] d. extruding the mixture in step c through a twin-screw extruder, shearing and granulat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com