Lightweight high-strength dense water type asphalt mixture and preparation method thereof

A kind of asphalt mixture and water-tight type technology, which is applied in the field of light-weight high-strength water-tight asphalt mixture and its preparation, can solve the problems of low density, the value of engineering application has not received due attention, and is in the initial stage. Small size, excellent comprehensive road performance, and the effect of improving the stress state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

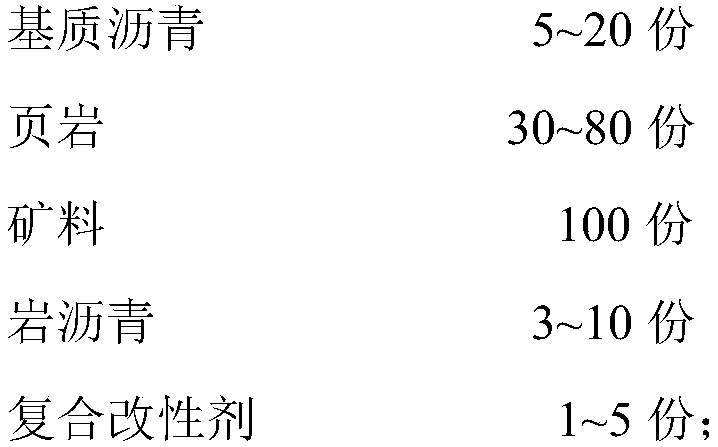

[0042] The invention also discloses a method for preparing light-weight, high-strength, water-dense asphalt mixture, which includes the following steps:

[0043] Step 1, weighing by parts by weight;

[0044] Step 2, adding the diabase heated to 175°C to 185°C into the mixing equipment, and stirring in the mixing equipment for 5-10 seconds;

[0045] Step 3. Add the shale heated to 120°C to 130°C and pre-coated with matrix asphalt into the product obtained in step 2 and stir for 5-10 seconds;

[0046] Step 4, add rock asphalt and composite modifier at normal temperature to the product obtained in step 3, stir for 5-10 seconds,

[0047] Step 5. Preheat the base asphalt to 155°C to 165°C, then add it to the product obtained in step 4 and stir for 30-45 seconds;

[0048] Step 6. Add limestone powder to the product obtained in step 5 and stir for 10-15 seconds to obtain a light, high-strength, water-dense asphalt mixture.

[0049] As a preferred technical solution, the stirring t...

Embodiment 1

[0053]Prepare light-weight high-strength water-dense asphalt mixture according to the following steps:

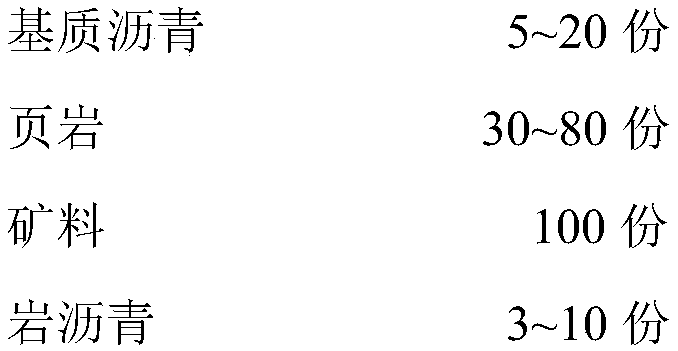

[0054] Step 1. Weigh according to the following parts by weight: 5 parts, 30 parts, 100 parts, 10 parts, and 5 parts of 90# matrix asphalt, shale, mineral material, Qingchuan rock asphalt, and composite modifier;

[0055] Among them, the particle size of shale is 3-15mm, and the mineral material is weighed by diabase and limestone powder with a particle size of 0.075-15mm at a weight ratio of 100:4;

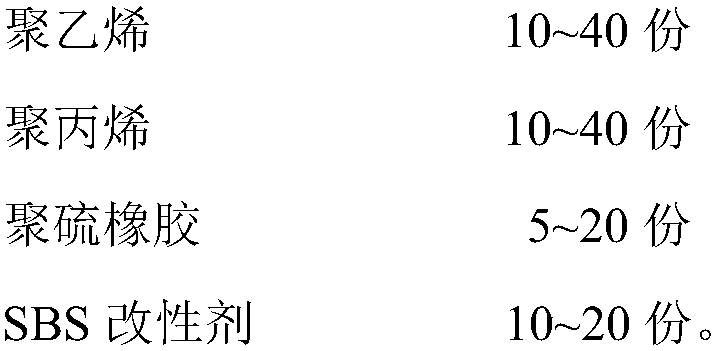

[0056] In addition, the composite modifier is composed of 10 parts of polyethylene, 10 parts of polypropylene, 5 parts of polysulfide rubber, and 10 parts of SBS modifier;

[0057] Step 2, adding the diabase heated to 175°C to 185°C into the mixing equipment, and stirring in the mixing equipment for 10 seconds;

[0058] Step 3. Add the shale heated to 120°C to 130°C and pre-coated with matrix asphalt into the product obtained in step 2 and stir for 10 seconds;

[0059] Step ...

Embodiment 2

[0065] Prepare light-weight high-strength water-dense asphalt mixture according to the following steps:

[0066] Step 1, weighing according to the following parts by weight: 110# base asphalt, shale, mineral material, Qingchuan rock asphalt, composite modifier are respectively 20 parts, 80 parts, 100 parts, 3 parts, 1 part;

[0067] Among them, the particle size of shale is 3-15mm, and the mineral material is weighed by diabase and limestone powder with a particle size of 0.075-15mm at a weight ratio of 100:7;

[0068] In addition, the composite modifier is composed of 40 parts of polyethylene, 40 parts of polypropylene, 20 parts of polysulfide rubber, and 20 parts of SBS modifier;

[0069] Step 2, adding the diabase heated to 175°C to 185°C into the mixing equipment, and stirring in the mixing equipment for 10 seconds;

[0070] Step 3. Add the shale heated to 120°C to 130°C and pre-coated with matrix asphalt into the product obtained in step 2 and stir for 10 seconds;

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com