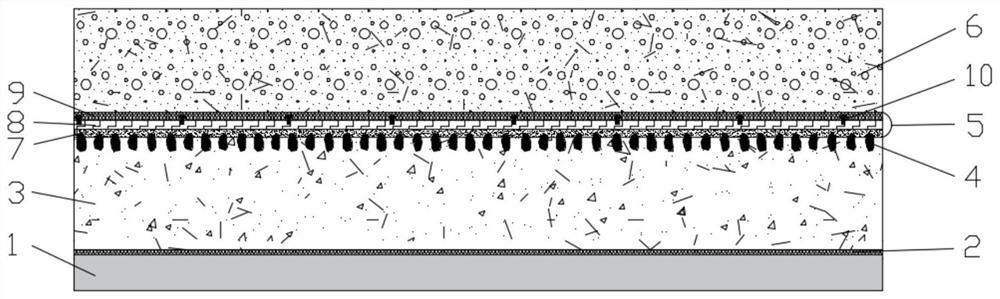

Bridge and tunnel fiber composite pouring flexible waterproof pavement and construction method

A fiber composite, flexible waterproof technology, applied in bridges, buildings, bridge parts, etc., can solve the problems of fatigue cracking of epoxy asphalt steel bridge deck pavement, insufficient durability of work with cracks, etc., to improve construction workability, The effect of reducing fatigue cracking and high modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] A bridge and tunnel fiber composite pouring flexible waterproof pavement and construction method, comprising the following steps:

[0051] (1) Sand blast and derust the steel bridge deck. The cleanliness of the steel bridge deck after sand blasting and rust removal reaches Sa2.5 level, and the roughness is 108 μm;

[0052] (2) Weigh 81 parts of bisphenol F epoxy resin, 15 parts of epichlorohydrin, and 6 parts of graphite powder, stir and mix, react at 60°C for 1 hour, and quickly add 65 parts of dicyandiamide at one time The curing agent w was reacted at 75°C for 30 minutes, and cooled to room temperature to prepare a two-stage thermoplastic epoxy resin waterproof adhesive layer.

[0053] Table 1 Performance parameters of the two-stage thermoplastic epoxy resin waterproof adhesive layer

[0054] Pilot projects unit Test Results Tensile Strength (23°C) MPa 3.6 Elongation at break (23°C) % ≥142 Water impermeability (0.3MPa, 24h) - imp...

Embodiment 2

[0073] A bridge and tunnel fiber composite pouring flexible waterproof pavement and construction method, comprising the following steps:

[0074] (1) Sand blast and derust the steel bridge deck. The cleanliness of the steel bridge deck after sand blasting and rust removal reaches Sa2.5 level, and the roughness is 104 μm;

[0075] (2) Weigh 82 parts of bisphenol F-type epoxy resin, 13 parts of epichlorohydrin, and 7 parts of graphite powder, stir and mix, react at 60°C for 1 hour, and quickly add 60 parts of anhydride curing agent w , reacted at 75°C for 30 minutes, and cooled to room temperature to prepare a two-stage thermoplastic epoxy resin waterproof adhesive layer.

[0076] Table 1 Performance parameters of the two-stage thermoplastic epoxy resin waterproof adhesive layer

[0077] Pilot projects unit Test Results Tensile Strength (23°C) MPa 3.8 Elongation at break (23°C) % ≥134 Water impermeability (0.3MPa, 24h) - impermeable wat...

Embodiment 3

[0096] A bridge and tunnel fiber composite pouring flexible waterproof pavement and construction method, comprising the following steps:

[0097] (1) Sand blast and derust the steel bridge deck. The cleanliness of the steel bridge deck after sand blasting and rust removal reaches Sa2.5 level, and the roughness is 112 μm;

[0098] (2) Weigh 85 parts of bisphenol F epoxy resin, 14 parts of epichlorohydrin, and 5 parts of graphite powder, stir and mix, react at 60°C for 1 hour, and quickly add 62 parts of polyamide curing agent at one time w, react at 75°C for 30 minutes, and cool to room temperature to prepare a two-stage thermoplastic epoxy resin waterproof adhesive layer.

[0099] Table 1 Performance parameters of the two-stage thermoplastic epoxy resin waterproof adhesive layer

[0100] Pilot projects unit Test Results Tensile Strength (23°C) MPa 3.9 Elongation at break (23°C) % ≥148 Water impermeability (0.3MPa, 24h) - impermeable w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com