Asphalt-based graphene asphalt warm mix agent and preparation method thereof

An asphalt-based and graphene-based technology, applied in building insulation materials, building components, buildings, etc., can solve the problems of few types, expensive warm mixes, poor universality, etc., and achieve good road performance and good compatibility and storage stability, high temperature anti-rutting performance improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

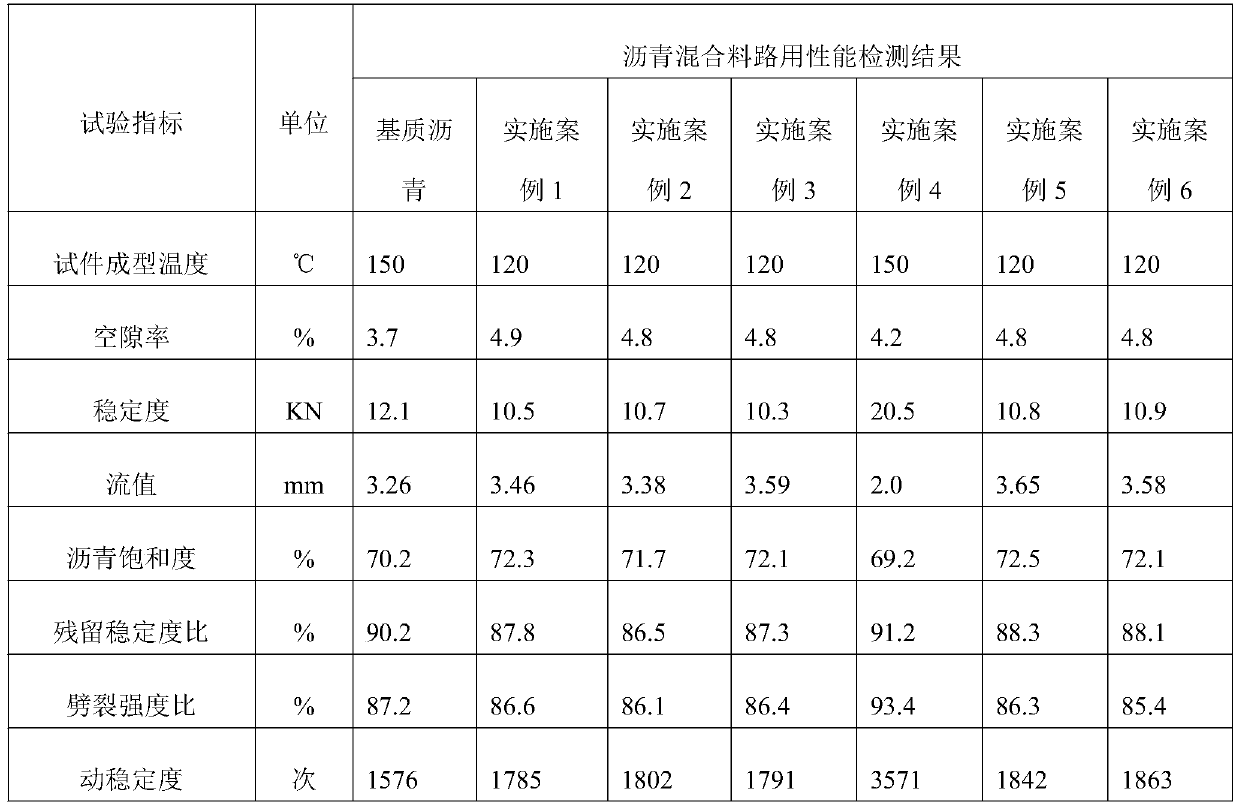

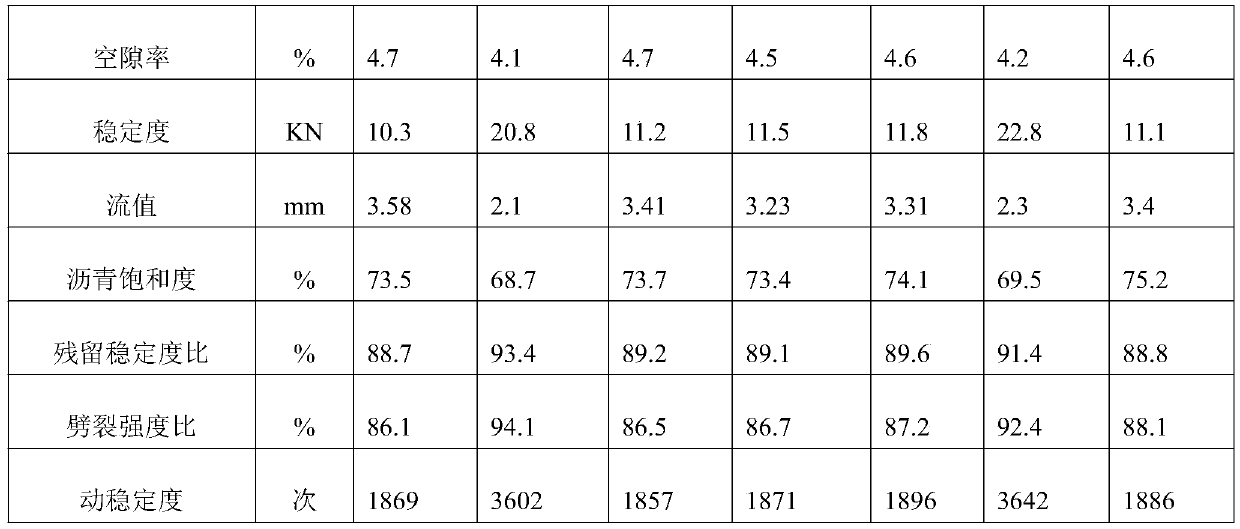

Examples

Embodiment 1

[0019] Add pitch-based graphene quantum dots and hexamine with a molar ratio of 1:1.1 into the reactor, add water-carrying agent xylene accounting for 30wt% of the total mass of the reaction raw materials, stir and heat up to reflux, and amidation reaction occurs at the reflux temperature, The reaction temperature was 150° C., and the reaction was carried out for 4 hours. Afterwards, the xylene was distilled off, vacuumed to a vacuum degree of 0.096 MPa, and the temperature was raised to 240° C. to carry out imidazoline cyclization reaction for 4 hours to obtain an imidazoline intermediate. Prepare an ethanol solution with a mass fraction of 50% from methyl acrylate with an imidazoline intermediate molar ratio of 1:1.1, and slowly add it dropwise to the imidazoline, and react for 12 hours under stirring at 40°C. After the reaction is completed, distill ethanol and unreacted Methyl acrylate to obtain pitch-based graphene-based asphalt warm mix agent.

[0020] Add the asphalt w...

Embodiment 2

[0022] Add pitch-based graphene quantum dots and hexamine with a molar ratio of 1:1.2 into the reactor, add water-carrying agent xylene accounting for 30wt% of the total mass of the reaction raw materials, stir and heat up to reflux, and amidation reaction occurs at the reflux temperature, The reaction temperature was 150° C., and the reaction was carried out for 4 hours. Afterwards, the xylene was distilled off, vacuumed to a vacuum degree of 0.096 MPa, and the temperature was raised to 240° C. to carry out imidazoline cyclization reaction for 4 hours to obtain an imidazoline intermediate. Prepare an ethanol solution with a mass fraction of 50% of methyl acrylate with an imidazoline intermediate molar ratio of 1:1.2, and slowly add it dropwise to the imidazoline, and react for 12 hours under stirring at 40°C. After the reaction is completed, distill ethanol and unreacted Methyl acrylate to obtain pitch-based graphene-based asphalt warm mix agent.

[0023] Add the asphalt war...

Embodiment 3

[0025] Add pitch-based graphene quantum dots and hexamine with a molar ratio of 1:1.1 into the reactor, add water-carrying agent xylene accounting for 30wt% of the total mass of the reaction raw materials, stir and heat up to reflux, and amidation reaction occurs at the reflux temperature, The reaction temperature was 150° C., and the reaction was carried out for 6 hours. Afterwards, the xylene was distilled off, the vacuum was evacuated to 0.096 MPa, and the temperature was raised to 240°C to carry out the imidazoline cyclization reaction for 6 hours to obtain the imidazoline intermediate. Prepare an ethanol solution with a mass fraction of 50% from methyl acrylate with an imidazoline intermediate molar ratio of 1:1.1, and slowly add it dropwise to the imidazoline, and react for 12 hours under stirring at 40°C. After the reaction is completed, distill ethanol and unreacted Methyl acrylate to obtain pitch-based graphene-based asphalt warm mix agent.

[0026] Add the asphalt w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com