High-performance foam warm mix asphalt and preparation method thereof

A technology of warm mix asphalt and foamed asphalt, applied in the field of high-performance foam warm mix asphalt and its preparation, can solve the problems of water stability and high temperature rutting resistance, reduce the adhesion between asphalt and stone interface, and increase the damage of asphalt pavement. Risks and other issues to improve water stability, high temperature rutting resistance, and reduce looseness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

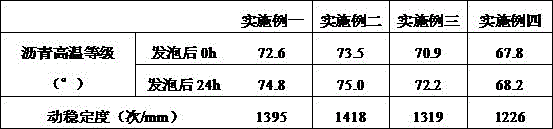

Examples

Embodiment 1

[0034] 【formula】

[0035] No. 70 road petroleum asphalt 100Kg; polyphosphoric acid 0.8Kg;

[0036] 1.5 Kg of diamine-type cationic asphalt emulsifier; 2 Kg of water.

[0037] 【Preparation】

[0038] (1) Heat the No. 70 road petroleum asphalt to 150°C;

[0039] (2) Add the formula amount of polyphosphoric acid into the hot asphalt and stir it thoroughly for 40 minutes;

[0040] (3) Add the stirred hot asphalt, water and diamine-type cationic asphalt emulsifier into the foaming device to form foamed asphalt in the foaming cavity;

[0041] (4) Immediately after the foamed asphalt is prepared, it is sprayed into the mixing tank and mixed with the aggregate to form an asphalt mixture.

[0042] Carry out relevant mixture performance tests, and at the same time take foamed asphalt samples for asphalt performance tests.

[0043] The foaming rate is 9 times, and the half-life is 12s.

Embodiment 2

[0045] 【formula】

[0046] No. 90 road petroleum asphalt 100Kg; polyphosphoric acid 1.5Kg;

[0047] 1 Kg of cetyltrimethylammonium bromide; 2.5Kg of water.

[0048] 【Preparation】

[0049] (1) Heat the No. 90 road petroleum asphalt to 160°C;

[0050] (2) Add the formula amount of polyphosphoric acid into the hot asphalt and stir it thoroughly for 50 minutes;

[0051] (3) Add the stirred hot asphalt, water and cetyltrimethylammonium bromide into the foaming device to make it form foamed asphalt in the foaming cavity;

[0052] (4) Immediately after the foamed asphalt is prepared, it is sprayed into the mixing tank and mixed with the aggregate to form an asphalt mixture.

[0053] Carry out relevant mixture performance tests, and at the same time take foamed asphalt samples for asphalt performance tests.

[0054] The foaming rate is 8.5 times, and the half-life is 11.6s.

Embodiment 3

[0056] 【formula】

[0057] No. 70 road petroleum asphalt 100Kg; polyphosphoric acid 0.5Kg;

[0058] Diamine type split cationic asphalt emulsifier 2 Kg; water 1.5Kg.

[0059] 【Preparation】

[0060] (1) Heat the No. 70 road petroleum asphalt to 140°C;

[0061] (2) Add the formula amount of polyphosphoric acid into the hot asphalt, and stir thoroughly for 60 minutes;

[0062] (3) Add the stirred hot asphalt, water and diamine-type cationic asphalt emulsifier into the foaming device to form foamed asphalt in the foaming cavity;

[0063] (4) Immediately after the foamed asphalt is prepared, it is sprayed into the mixing tank and mixed with the aggregate to form an asphalt mixture.

[0064] Carry out relevant mixture performance tests, and at the same time take foamed asphalt samples for asphalt performance tests.

[0065] The foaming rate is 8.7 times, and the half-life is 10.9s.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com