Asphalt mixture with high anti-rut capability and preparation method therefor

A technology of asphalt mixture and anti-rutting agent, which is applied in the field of pavement materials, can solve the problems of poor compatibility between anti-rutting agent and asphalt, high cost of anti-rutting agent, segregation, etc., and achieve an increase in softening point, strong engineering application value, The effect of simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A kind of AC-13 type asphalt mixture with high anti-rutting ability is characterized in that: it is composed of the following components by weight percentage:

[0030] Mineral material adopts limestone: 95.4Kg,

[0031] Asphalt adopts 70# matrix: 4.6Kg;

[0032] Anti-rutting agent: 0.184Kg.

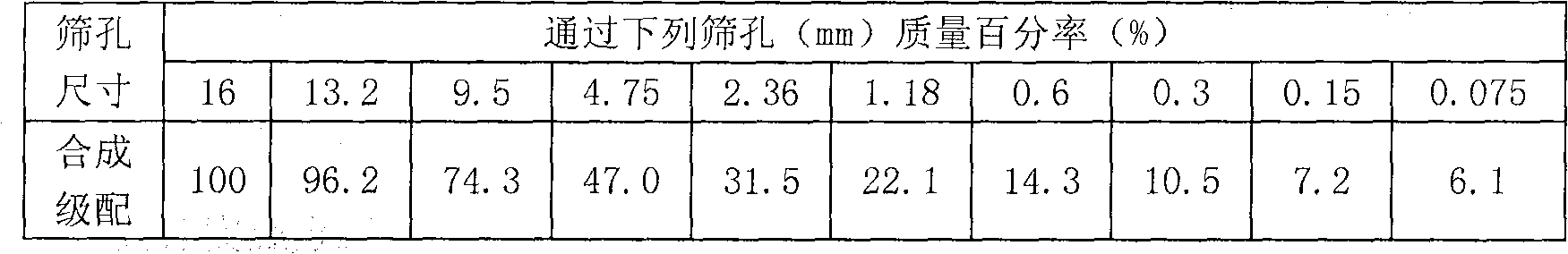

[0033] Among them, the mineral materials adopt the following gradation:

[0034]

[0035] Wherein, anti-rutting agent is made of the following components by weight percentage:

[0036] Aluminum trichloride hexahydrate: 6kg;

[0037] Waste rubber powder: 2kg;

[0038] Drinking water 92kg.

[0039] The preparation method of the anti-rutting agent is as follows: take 6 kg of aluminum chloride hexahydrate and 92 kg of drinking water at room temperature, mix and stir evenly, then slowly add 2 kg of 40 mesh waste rubber powder into the aqueous aluminum chloride solution, and stir while adding, until The whole solution is mixed evenly to obtain the anti-rutting agent.

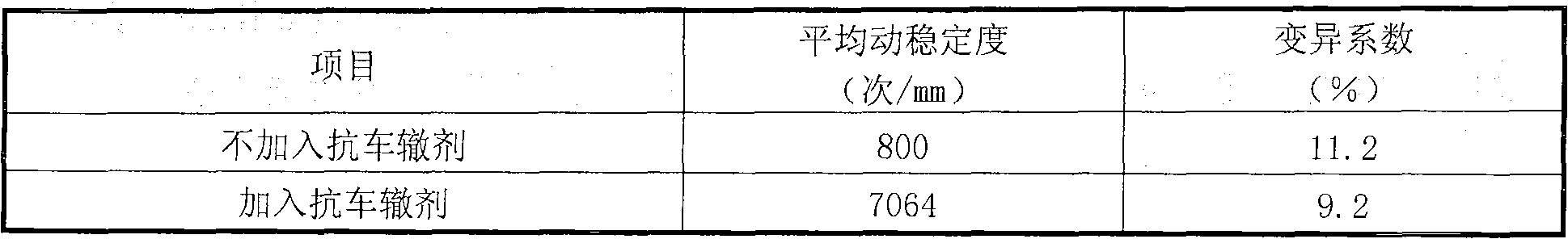

[0040] T...

Embodiment 2

[0045] An AC-20 rubber powder modified asphalt mixture with high rutting resistance, characterized in that it consists of the following components in weight percentage:

[0046] Mineral material adopts limestone: 95.2Kg,

[0047] Asphalt adopts rubber powder modified asphalt: 4.8Kg;

[0048] Anti-rutting agent: 0.24Kg.

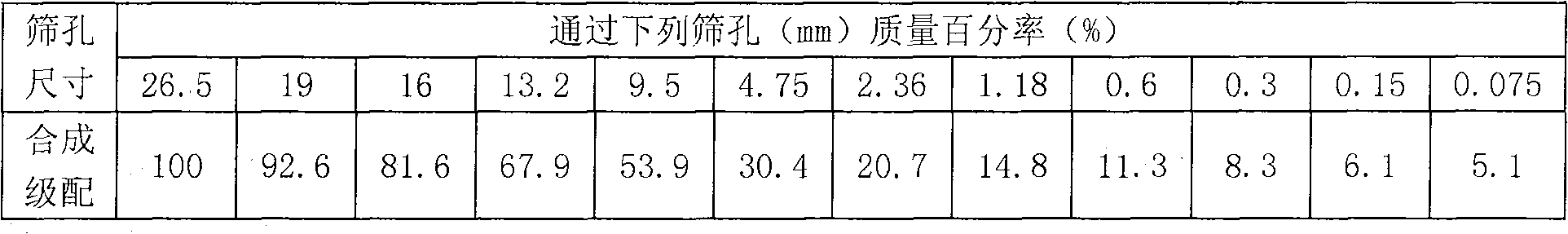

[0049] Among them, the mineral materials adopt the following gradation:

[0050]

[0051] Wherein, the anti-rutting agent is composed of the following components by weight percentage:

[0052] Aluminum trichloride hexahydrate: 5kg;

[0053] Waste rubber powder: 3kg;

[0054] Drinking water 92kg.

[0055] The preparation method of the anti-rutting agent is as follows: take 5 kg of aluminum trichloride hexahydrate and 92 kg of drinking water at room temperature, mix and stir evenly, then slowly add 3 kg of 40 mesh waste rubber powder into the aqueous aluminum chloride solution, and stir while adding, until The whole solution is mixed evenly to obtain th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com