Method for preparing water-soluble cationic lignin-based flocculant by semi-dry method

A water-soluble cation and flocculant technology, which is applied in the field of material science, can solve the problems of large dosage, small dosage, and large flocs, and achieve the effects of less water consumption, simplified preparation conditions, and strong positive charge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

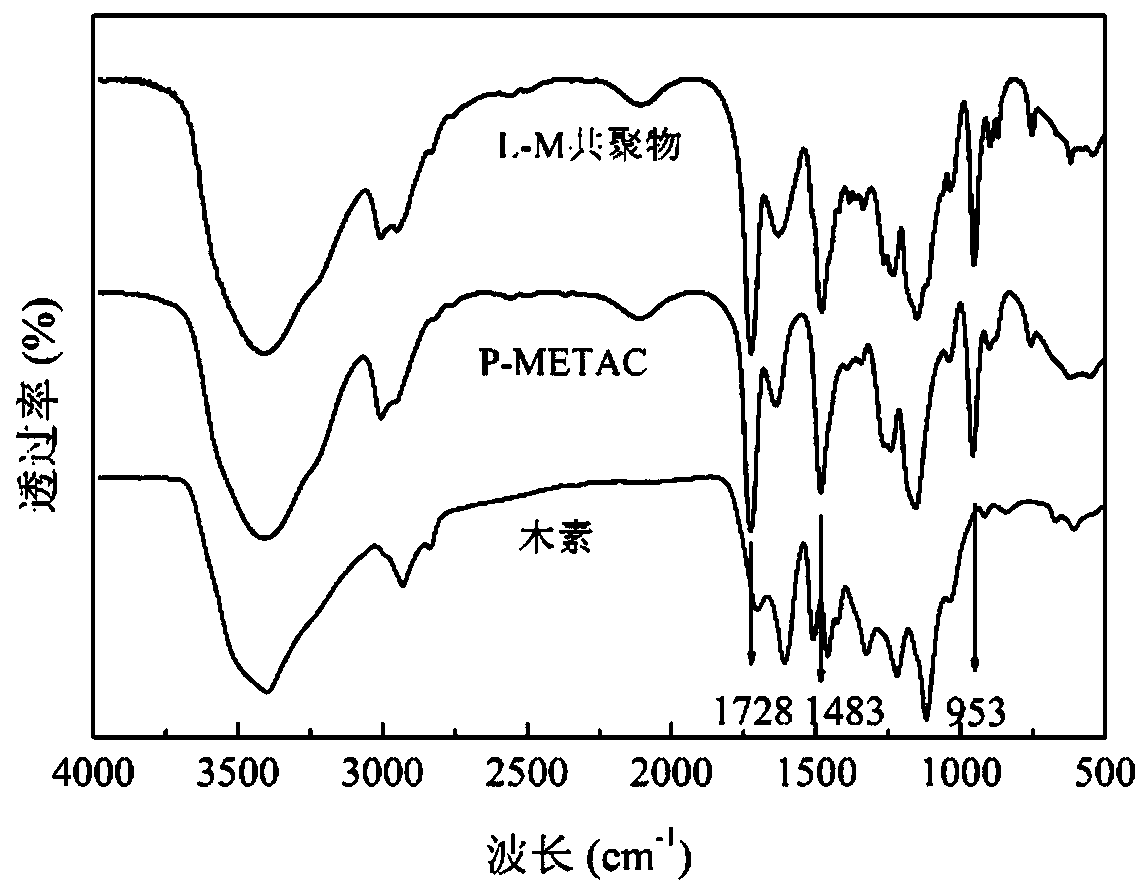

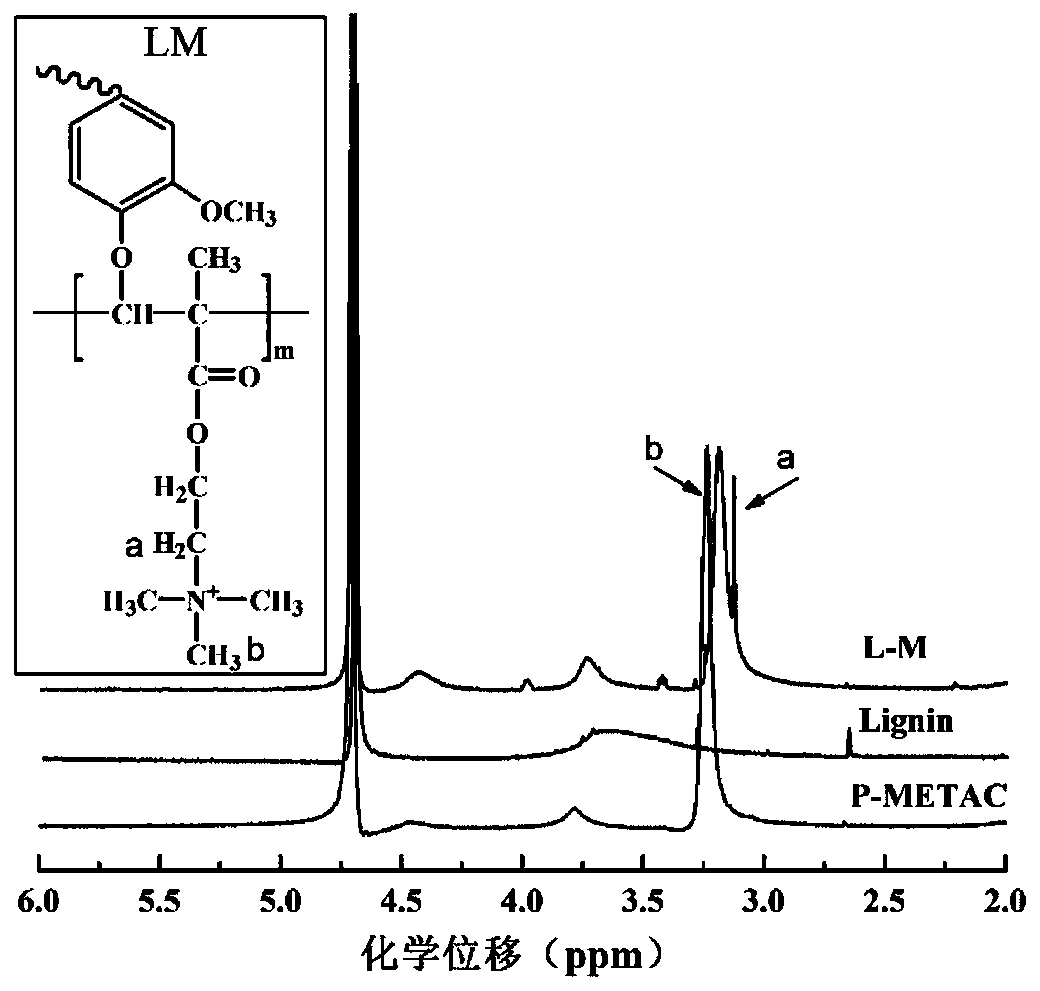

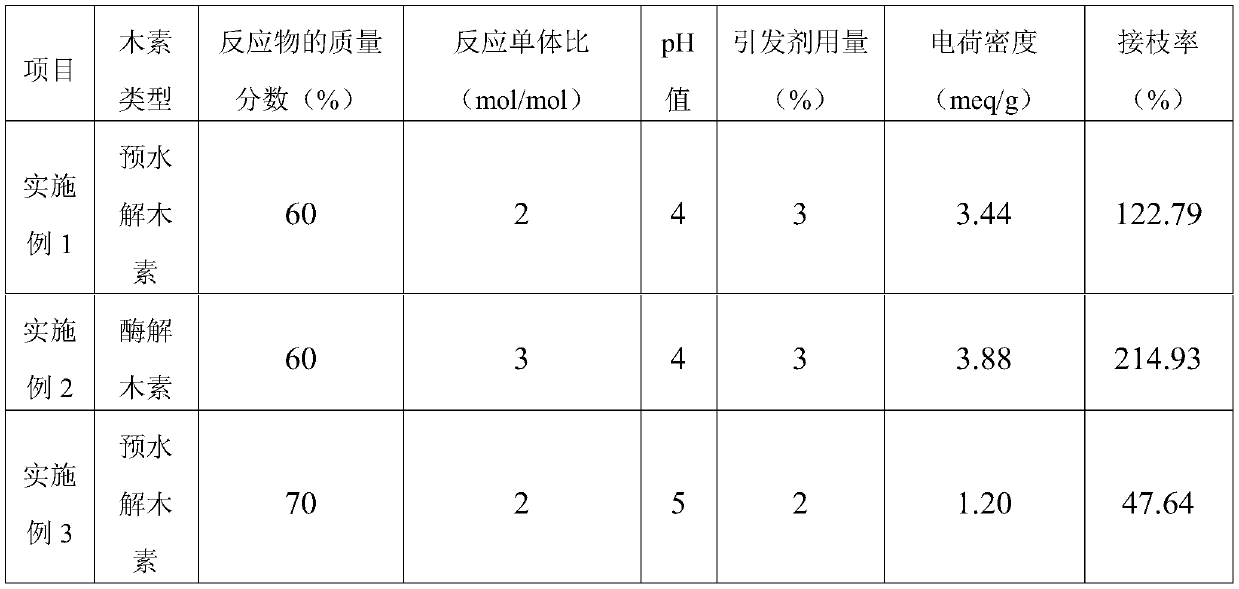

[0034] Weigh 2g of prehydrolyzed lignin, add 6.22g of METAC solution with a mass concentration of 75% and 2.89g of deionized water, fully mix and dissolve in a No. 5 ziplock bag, adjust the pH value of the reaction system to 5 to obtain a reaction solution , Nitrogen gas to fully remove the oxygen in the reaction system, after adding 0.04g of potassium persulfate, stop the nitrogen gas flow, seal the ziplock bag and place it in a water bath at 70°C for 1.5h to obtain the crude lignin grafted METAC product.

[0035] The crude product was centrifuged and washed with absolute ethanol (3000r / min), and then dialyzed with a dialysis bag (MWCO: 3000Da) for 48h. Obtain lignin-METAC graft copolymer (referred to as L-M graft copolymer) through hot air drying.

Embodiment 2

[0037] Weigh 2g of enzymatic lignin, add 9.33g of METAC solution with a mass concentration of 75% and 3.67g of deionized water, mix and dissolve them in a No. 5 ziplock bag, adjust the pH value of the reaction system to 4 to obtain a reaction solution, and pass Nitrogen gas is used to fully remove the oxygen in the reaction system. After adding 0.06g of potassium persulfate, the nitrogen gas flow is stopped, and the ziplock bag is sealed and placed in a water bath at 70°C for 1.5 hours to obtain the crude product of lignin grafted METAC.

[0038] The crude product was centrifuged and washed with absolute ethanol (3000r / min), and then dialyzed with a dialysis bag (MWCO: 3000Da) for 48h. Obtain lignin-METAC graft copolymer (referred to as L-M graft copolymer) through hot air drying.

Embodiment 3

[0040] Weigh 2g of prehydrolyzed lignin, add 6.22g of METAC solution with a mass concentration of 75% and 1.30g of deionized water, fully mix and dissolve them in a No. 5 ziplock bag, adjust the pH value of the reaction system to 4 to obtain a reaction solution , nitrogen gas to remove oxygen in the reaction system, after adding 0.04g of potassium persulfate, stop the nitrogen gas flow, seal the ziplock bag and place it in a water bath at 70°C for 1.5h to obtain lignin-METAC graft copolymer crude product.

[0041] The crude product was centrifuged and washed with absolute ethanol (3000r / min), and then dialyzed with a dialysis bag (MWCO: 3000Da) for 48h. Obtain lignin-METAC graft copolymer (referred to as L-M graft copolymer) through hot air drying.

[0042] Implementation prepares the reaction condition of L-M graft copolymer, and solubility and graft ratio are as follows:

[0043] Table 1:

[0044]

[0045] In the present invention, the graft copolymerization of lignin ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com