Preparation of catalyst with carrier of ceria-zirconia solid solution and application of catalyst in NOx removal

A cerium-zirconium solid solution and catalyst technology, applied in the selective catalytic oxidation of NO, the preparation of supported transition metal chromium, and the field of catalyst preparation, can solve the problems of complicated methods and complicated preparation methods, and achieve simplified preparation conditions and simplified The effect of the preparation step, promoting the probability of being oxidized

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

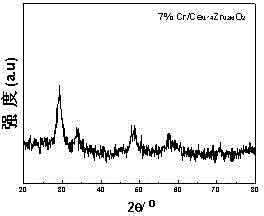

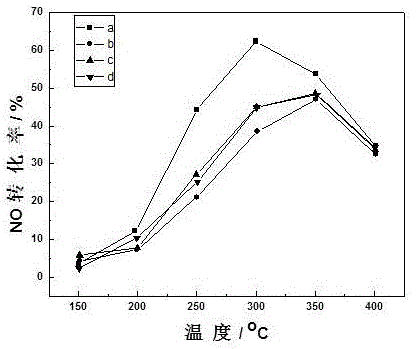

[0026] The catalyst for catalytic oxidation of NO prepared according to the present invention, wherein the Ce / Zr mass ratio of the cerium-zirconium solid solution carrier is 0.25:1, and the loading amount of the main active component chromium is 7% (mass fraction).

[0027] (1) Preparation of cerium-zirconium solid solution carrier by hydration method:

[0028] Dissolve cerium nitrate and zirconium oxychloride (according to the above ratio) in deionized water, stir for 2 hours, reflux in a water bath at 60°C for 4 hours, dry in an oven at 120°C for 12 hours, and finally calcinate at 500°C in air for 6 Hour;

[0029] (2) Loading active component chromium to cerium-zirconium solid solution carrier by impregnation method:

[0030] Dissolve chromium nitrate and cerium-zirconium solid solution carrier in deionized water according to the above ratio, stir for 2 hours, reflux in a water bath at 60°C for 4 hours, dry in an oven at 120°C for 12 hours, and finally calcinate at 400°C in...

Embodiment 2

[0032] The catalyst for catalytic oxidation of NO produced according to the present invention, wherein the Ce / Zr of the cerium-zirconium solid solution carrier is 4:1 (mass ratio), and the loading amount of the main active component chromium is 10% (mass fraction).

[0033] (1) Preparation of cerium-zirconium solid solution carrier by hydration method:

[0034] Dissolve cerium nitrate and zirconium oxychloride (according to the above ratio) in deionized water, stir for 2 hours, reflux in a water bath at 60°C for 4 hours, dry in an oven at 120°C for 12 hours, and finally calcinate at 500°C in air for 6 Hour;

[0035] (2) Loading active component chromium to cerium-zirconium solid solution carrier by impregnation method:

[0036] Dissolve chromium nitrate and cerium-zirconium solid solution carrier in deionized water according to the above ratio, stir for 2 hours, reflux in a water bath at 60°C for 4 hours, dry in an oven at 120°C for 12 hours, and finally calcinate at 500°C in...

Embodiment 3

[0038] The catalyst for catalytic oxidation of NO prepared according to the present invention, wherein the Ce / Zr of the cerium-zirconium solid solution carrier is 1:1 (mass ratio), and the loading amount of the main active component chromium is 10% (mass fraction).

[0039] (1) Preparation of cerium-zirconium solid solution carrier by hydration method:

[0040] Dissolve cerium nitrate and zirconium oxychloride (according to the above ratio) in deionized water, stir for 2 hours, reflux in a water bath at 80°C for 4 hours, dry in an oven at 120°C for 12 hours, and finally calcinate at 500°C in air for 6 Hour;

[0041] (2) Loading active component chromium to cerium-zirconium solid solution carrier by impregnation method:

[0042] Dissolve chromium nitrate and cerium-zirconium solid solution carrier in deionized water according to the above ratio, stir for 2 hours, reflux in a water bath at 60°C for 4 hours, dry in an oven at 120°C for 12 hours, and finally calcinate at 500°C in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com