Patents

Literature

58results about How to "Reduce production water consumption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

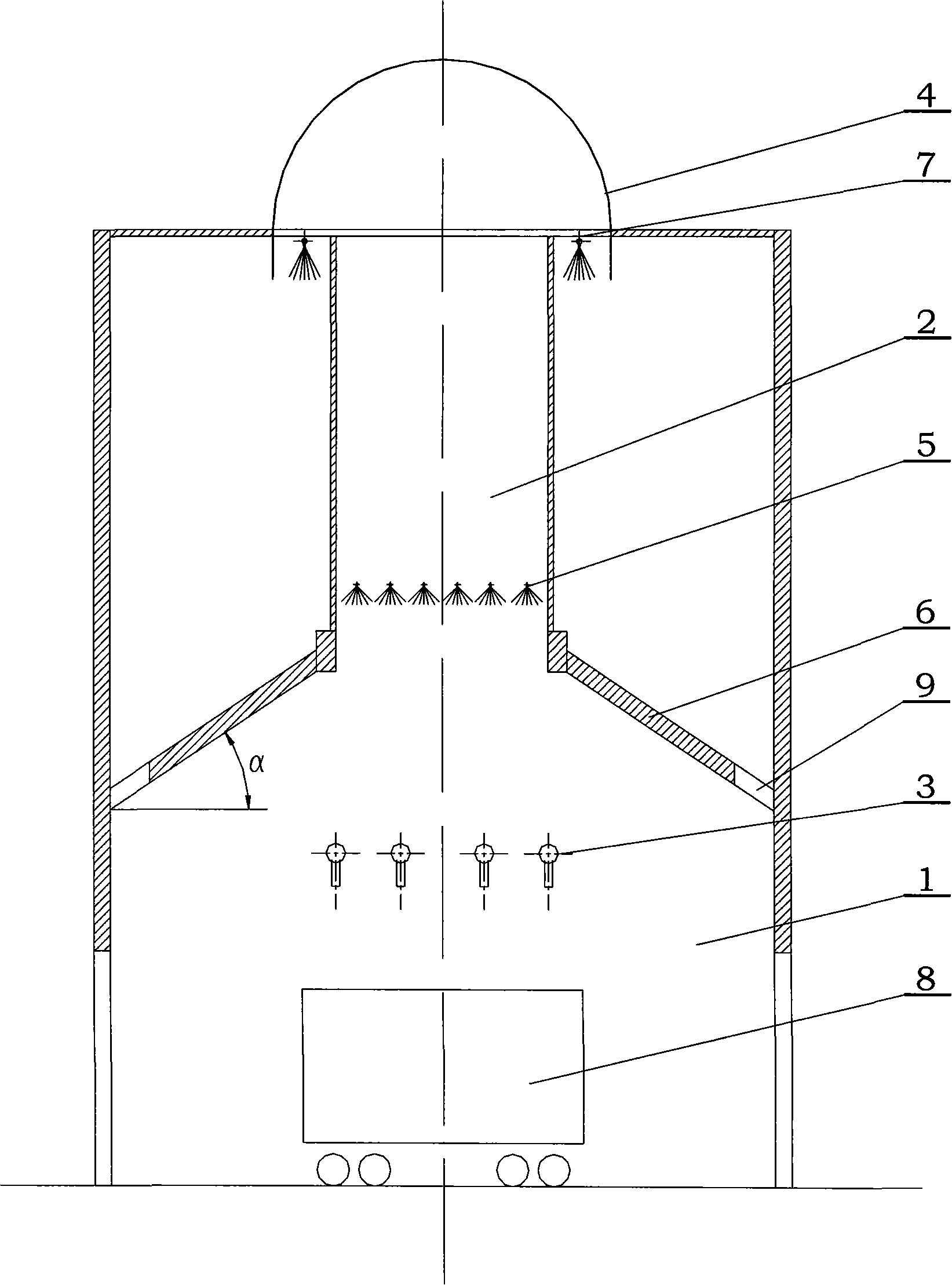

Dome type dust removing coke quenching machine

The invention relates to a dome-like dedusting coke quenching tower, which comprises the following parts: a coke quenching procedure at the bottom and a deduesting procedure at the top, wherein the coke quenching procedure is equipped with a coke quenching injecting pipe; the dedusting procedure is divided into three lattices; the bottom of two side lattices sealed by a tipping plate; the bottom of the tipping plate is equipped with blow-off hole; the included angle alpha of the tipping plate and the horizontal surface is 10-75 degree; the top of the coke quenching injecting pipe and the middle lattice entrance of the dedusting procedure are equipped with a plurality of washing and cooling devices; the top of washing and cooling devices and the top of the coke quenching tower are equipped with dome-like dedusting device which covers the middle lattice and two side lattices of the coke quenching tower dedusting procedure. The invention reduces the dust content after washing the polluting vapor with the water fog, cooling the polluting vapor, settling the polluting vapor gravitively and changing the direction of the gas flowing, which reduces the water consumption.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

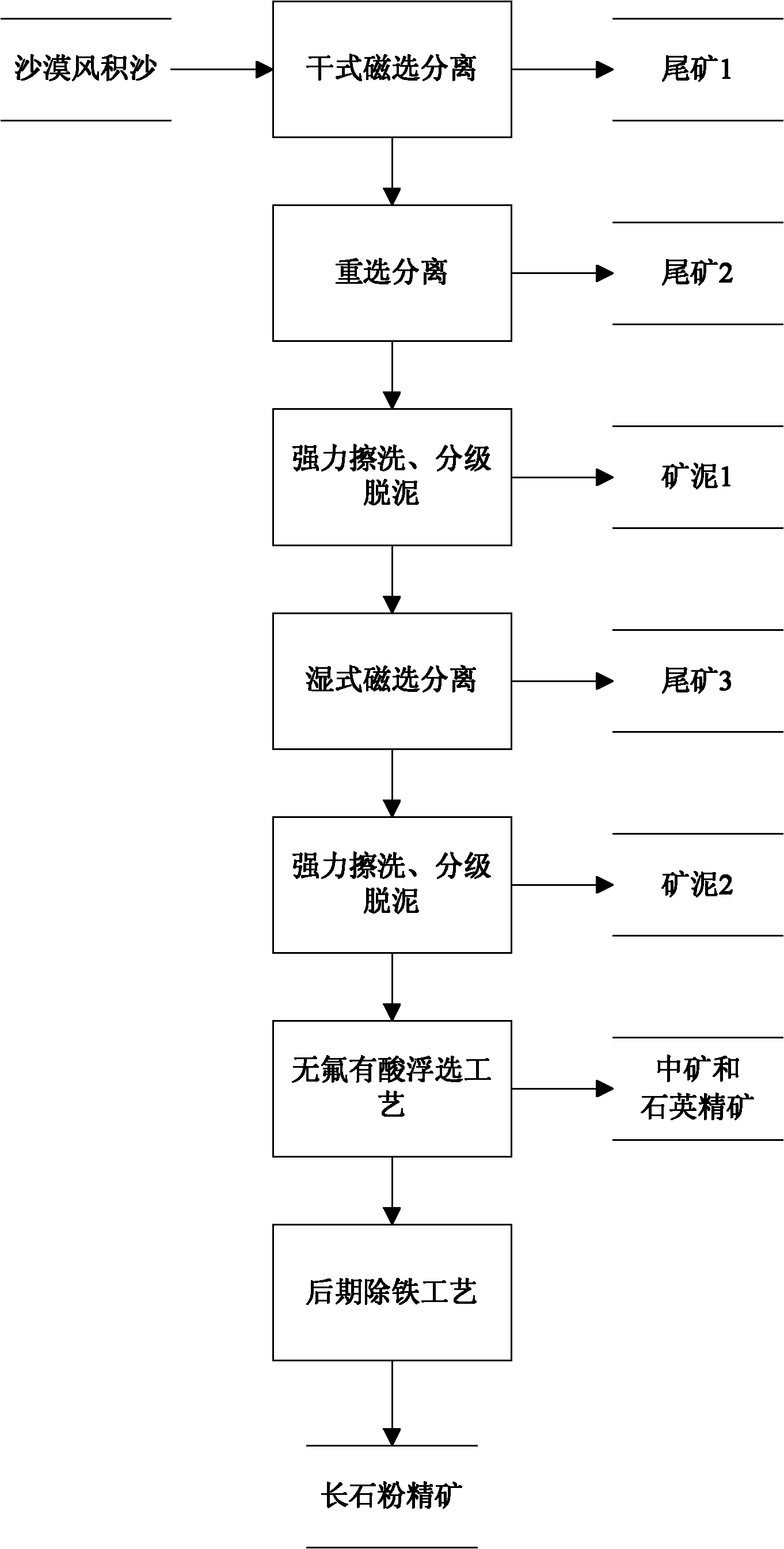

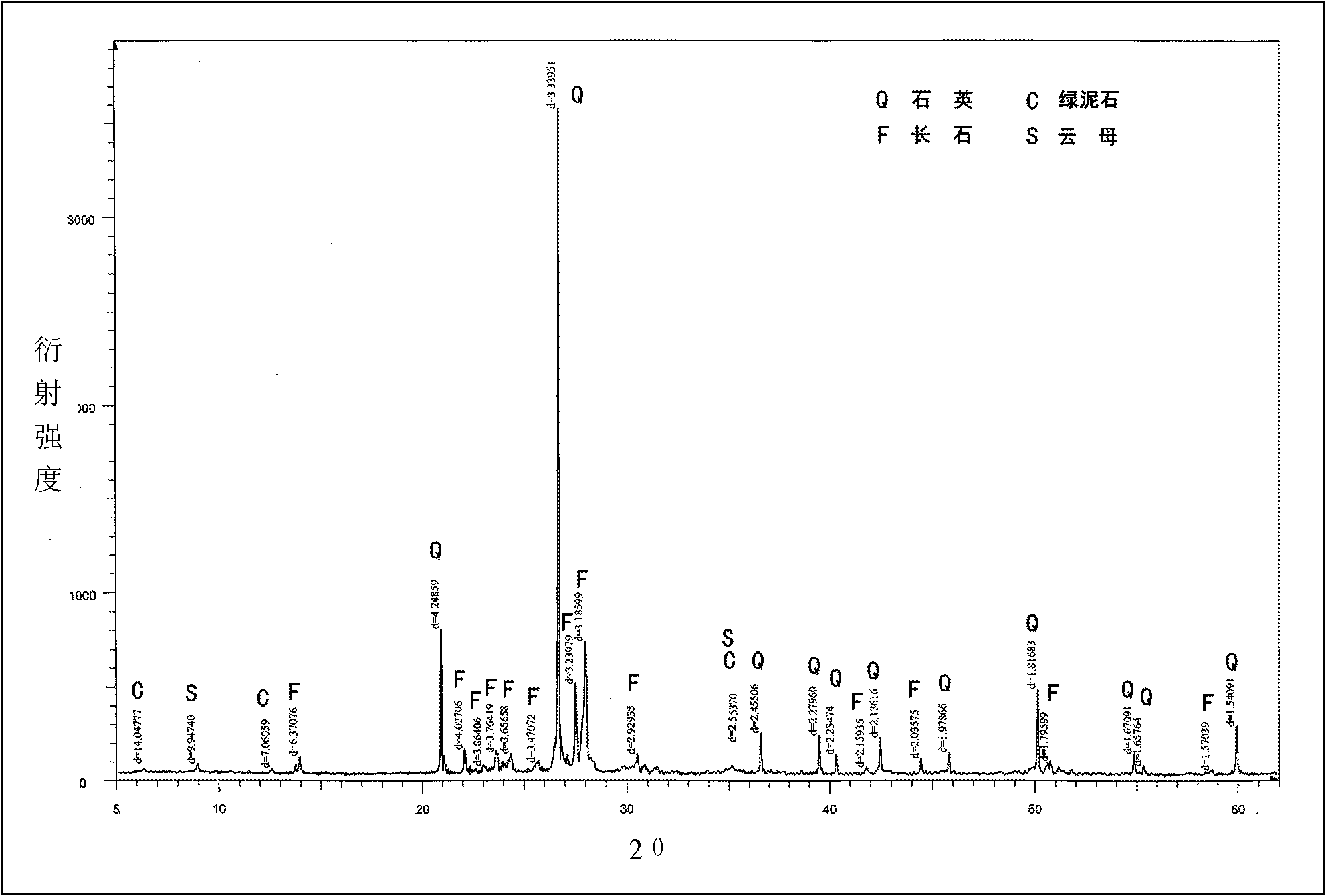

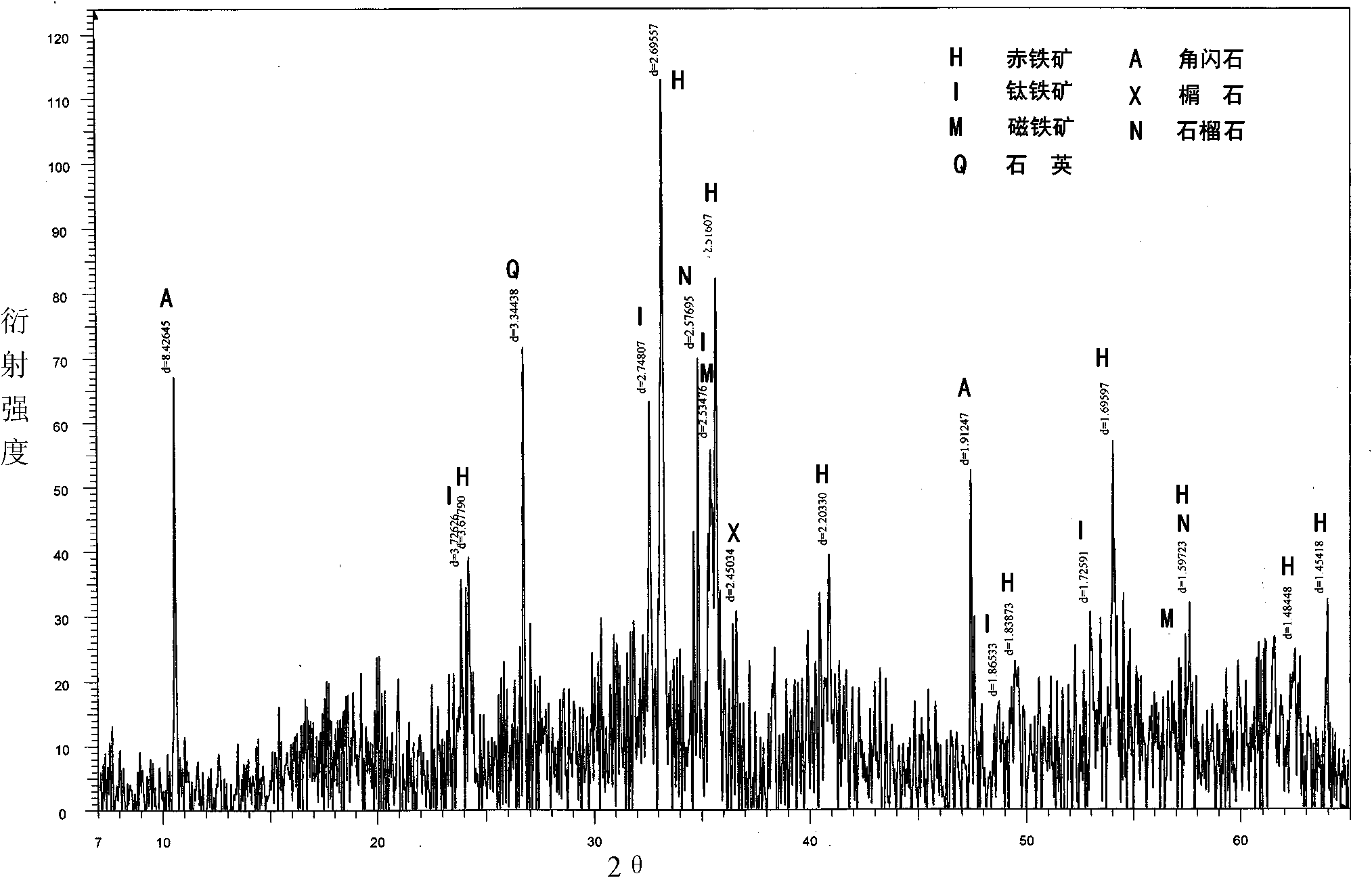

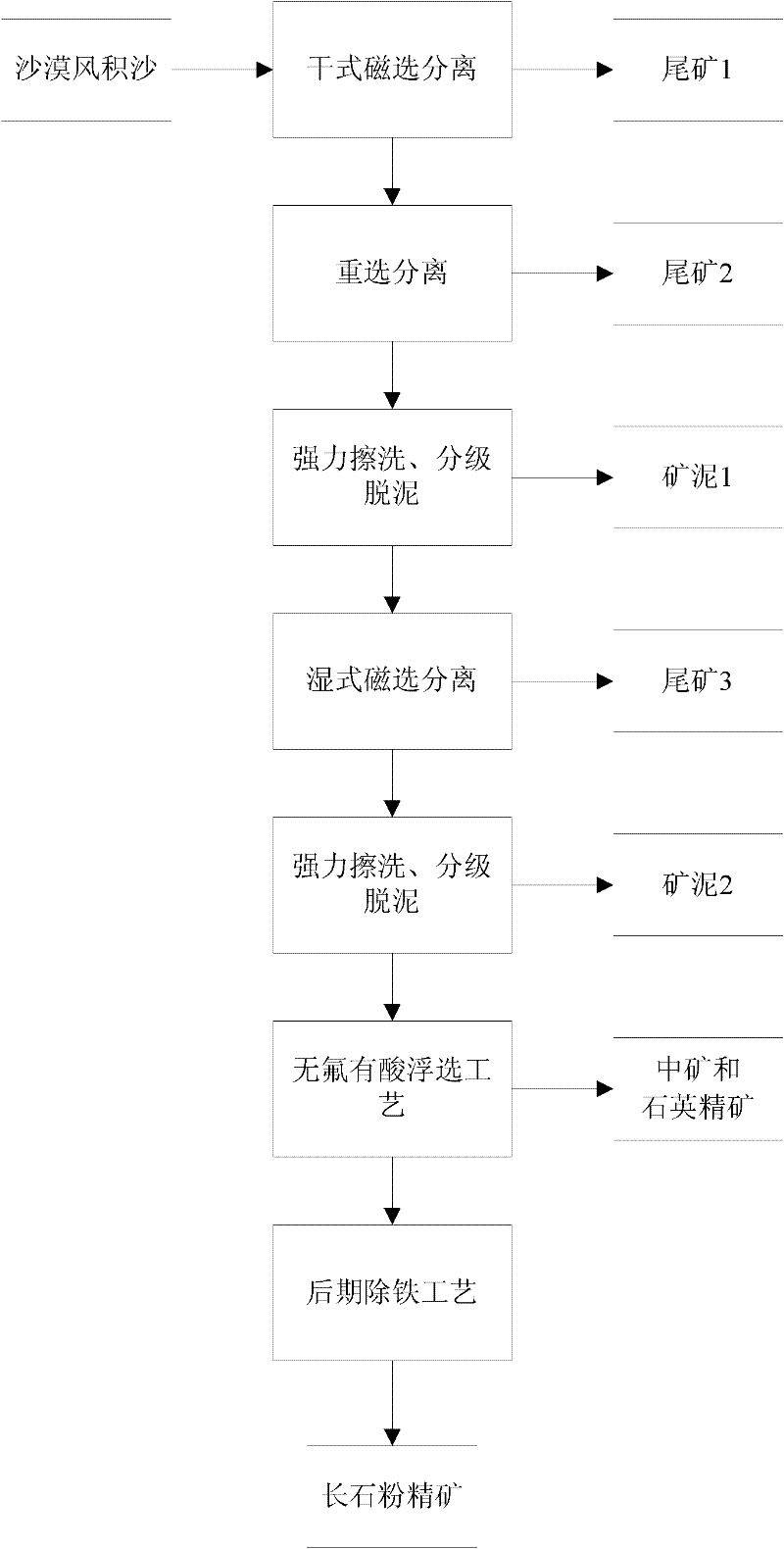

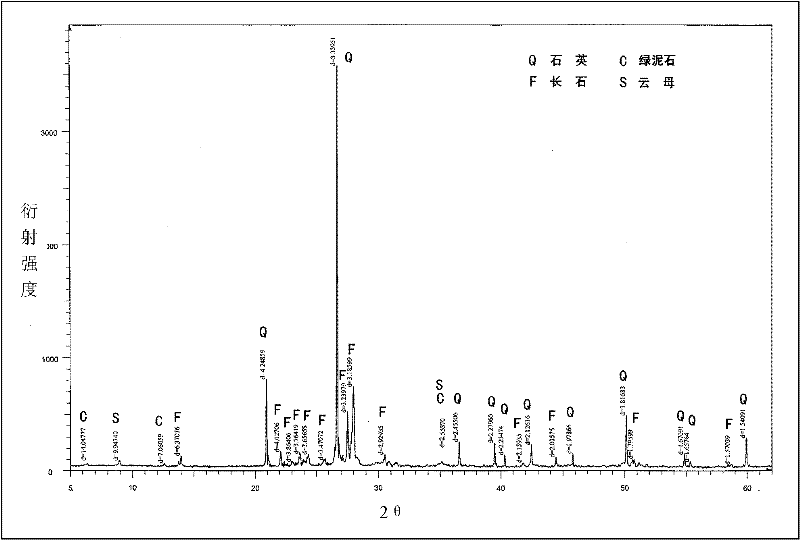

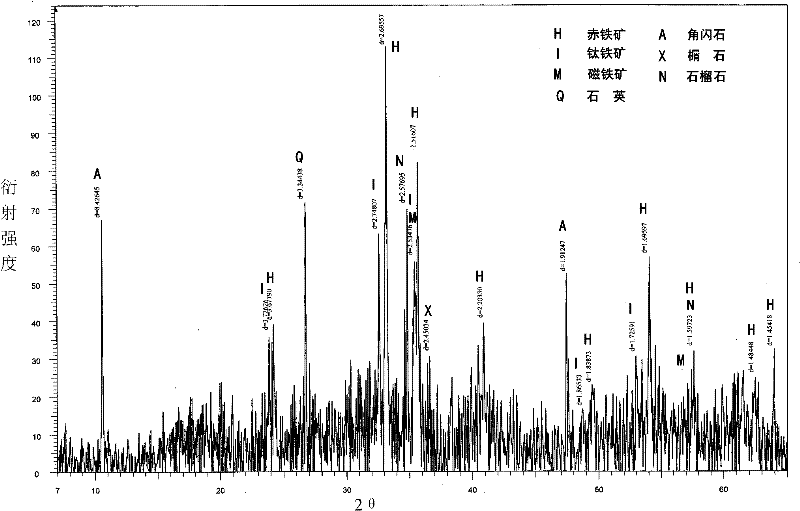

Method for preparing feldspar powder concentrate by mineral separation of aeolian sand in desert

ActiveCN101885489AReduce production water consumptionReduce manufacturing costSilicon compoundsIntermediate stageEnergy consumption

The invention belongs to an industrial utilization method of aeolian sand in desert, in particular to a method for preparing feldspar powder concentrate by mineral separation of aeolian sand in desert. The method comprises an early-stage ferrum-removal process, a middle-stage feldspar flotation separation process and a later-stage ferrum-removal process. The early-stage ferrum-removal process comprises the following specific steps: firstly, carrying out dry magnetic separation on the aeolian sand in the desert; carrying out reselection and separation on the concentrate obtained after dry magnetic separation; carrying out powerful scrubbing and sizing-desliming on the concentrate obtained after reselection and separation; and carrying out wet magnetic separation to obtain the ferrum-removal concentrate for the middle-stage feldspar flotation separation process, and carrying out the later-stage ferrum-removal process on the feldspar mineral aggregate obtained in the middle-stage feldspar flotation separation process to finally obtain the feldspar powder concentrate. The processes of the invention have the advantages of water conservation, reduced energy consumption and low cost, and can fully utilize the existing aeolian sand resources to produce the high-quality feldspar powder concentrate.

Owner:CHANGSHA RES INST OF MINING & METALLURGY +1

Method for processing acorn starch

InactiveCN101768222AReduce production water consumptionShorten the production cycleUltrasound assistedVacuum drying

The invention discloses a method for processing acorn starch, which comprises the following steps: crushing acorn kernel into one fourth to one eighth size of the original kernel; removing tannin in the acorn kernel by adopting an ultrasound assisted three-stage countercurrent leaching process, wherein the process conditions of each stage in the ultrasound assisted three-stage countercurrent leaching is that: the ratio of material to water is 1:5-1:6; the temperature is 40 to 45 DEG C; the time is 50 to 60 min; the ultrasonic power is 262 to 454 W, and the frequency is 25.6 to 47.6 kHz; bleaching with water which is two times of the acorn kernel, and pulping, dehydrating and bleaching to remove impurities; finally, drying wet acorn starch for 60 to 80 minutes under the conditions that the vacuum degree is 0.08 to 0.09 MPa and the temperature is 50 to 60 DEG C by adopting vacuum drying technology and device to, and crushing and screening to obtain pure acorn starch products with the water content of lower than 12 percent and the tannin content of only 0.175 percent. The method for processing the acorn starch has the advantages of low water consumption in production, low wastewater emission and short production cycle, wherein the time used in each cycle is about four hours.

Owner:SHAANXI UNIV OF TECH

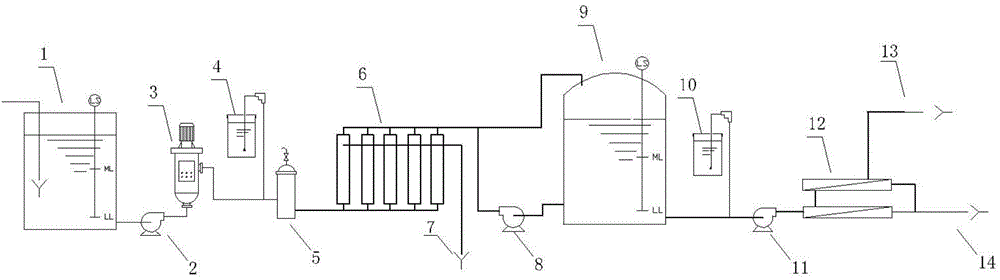

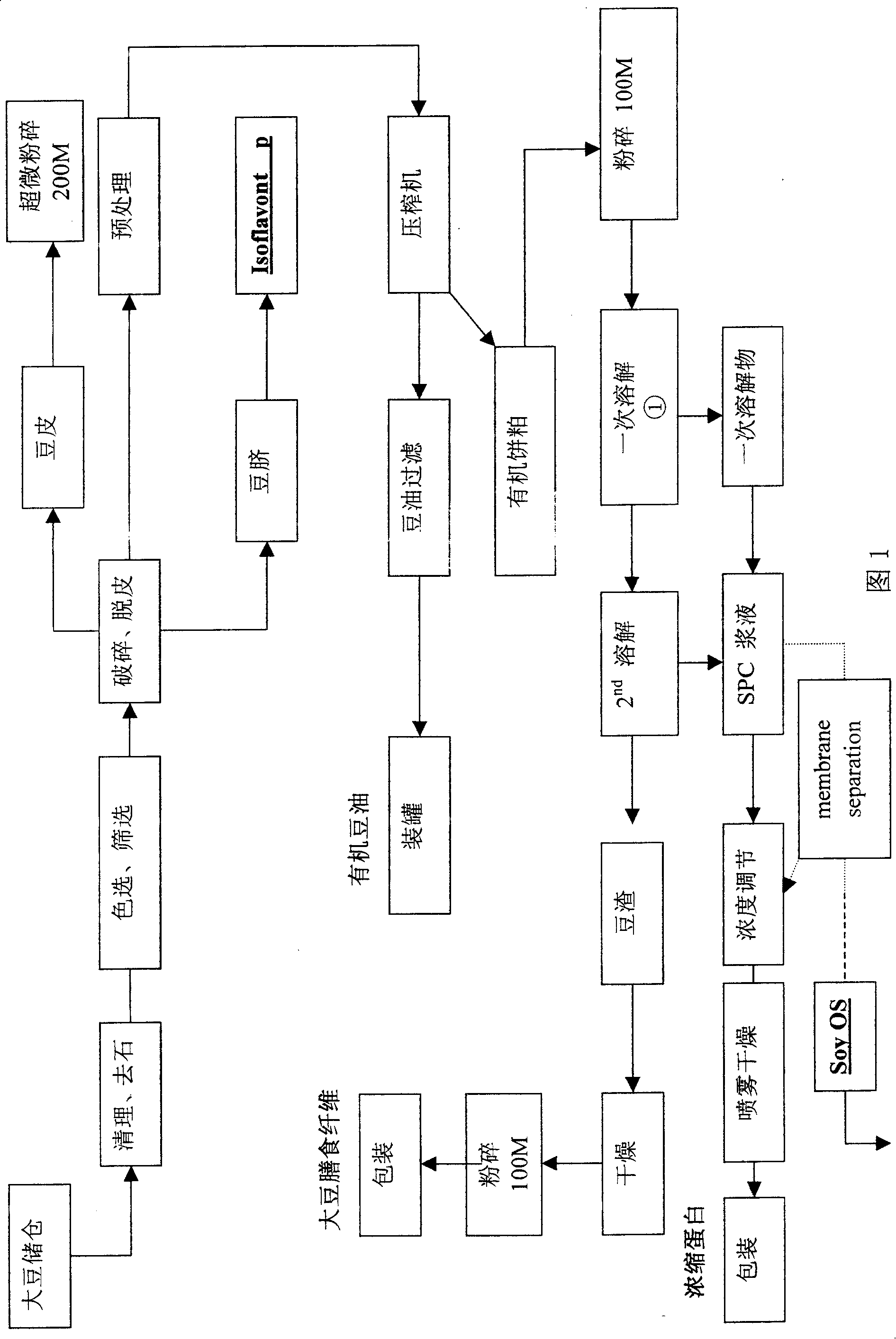

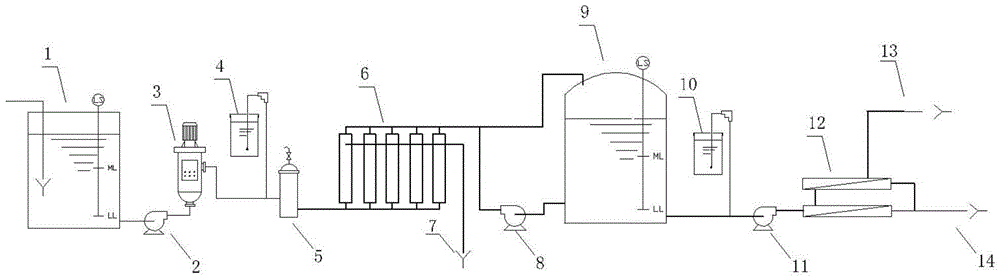

Device and method for realizing printing and dyeing dyed wastewater reuse and dye recovery

ActiveCN104609605AAchieve retentionAchieve reuseMultistage water/sewage treatmentSeparation technologyUltrafiltration

The invention relates to a printing and dyeing wastewater reuse, and particularly relates to a device and a method for printing and dyeing wastewater water-soluble dye recovery on the basis of a membrane separation technology. The device comprises a raw water booster pump, a self-cleaning filter, a precise filter, an ultrafiltration membrane assembly, an ultrafiltration backwash pump, an ultrafiltration water tank, a high-pressure pump, a nanofiltration membrane assembly, and a reducer and scale inhibitor pouring system which are communicated with a wastewater collection pool. The method comprises the steps of draining the dyed wastewater to the wastewater collection pool and pumping the dyed wastewater in the self-cleaning filter through the raw water booster pump to remove large-particle suspended matters and impurities, then entering the wastewater into the precise filter to remove the remainder suspended matters, then entering the wastewater into an ultrafiltration membrane to remove bacteria, colloids and macromolecular organic compounds, finally pumping the wastewater in a nanofiltration membrane device through the high-pressure pump to remove micromolecular organic compounds and divalent ions, thereby producing high-quality reclaimed water and simultaneously intercepting and recovering most of activated dye molecules.

Owner:DALIAN UNIV OF TECH

Method for advanced treatment of yeast waste water

InactiveCN101172680AReduce concentrationGood removal effectWater/sewage treatment by flocculation/precipitationWater/sewage treatment by sorptionFlocculationYeast

The invention relates to an advanced treatment method of yeast waste water, the advanced treatment method of yeast waste water is characterized in that the following steps are included: the inorganic flocculant is added in yeast waste water biochemical water after biochemical treatment, and quickly stirred in a stirring rotation rate ranging from 300 to 600 revolutions per minute; wherein, the inorganic flocculant is aluminium salt or iron salt, and the adding amount of the inorganic flocculant complies with that: 11to 15mM Fe3+ or Al3+ is added into a gram COD of yeast waste water; and then the organic flocculant is added and stirred; the organic flocculant is cation type polyacrylamide, 2 to 10 milligrams of organic flocculant is added in each liter of yeast waste water biochemical water; after stirring, the mixture enters into the settling pond for separating the solid from the liquid as well as settling the flocculation; the supernatant solution is directly discharged or further removed the COD and the chrominance by active carbon absorption. The invention has advantages of high removal rate of COD and chrominance.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

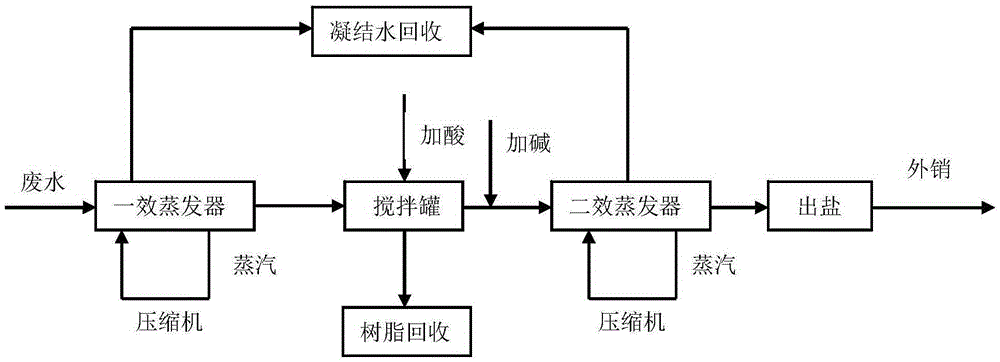

Method for treating rubber vulcanization accelerator wastewater by combination of MVR (mechanical vapor recompression) evaporation and chemical treatment

ActiveCN105417822AReduce sewage CODLow running costMultistage water/sewage treatmentNature of treatment waterChemistryVapor phase

The invention provides a method for treating rubber vulcanization accelerator wastewater by combination of MVR (mechanical vapor recompression) evaporation and chemical treatment. The method comprises the steps of putting wastewater into a first effect evaporator of the MVR, heating steam until the evaporating temperature of a vapor phase is 80 to 100 DEG C, evaporating supplied material wastewater and enabling the salt concentration of same to reach 15 percent to 25 percent; adding the wastewater with 15 percent to 25 percent of salt concentration by evaporating into a stirring tank with a stirring function for performing acid adjustment and adjusting the pH to 1 to 5, performing filter pressing and recycling resin after mixing and sedimenting for 30 to 60 min; adding alkali into the wastewater after filter pressing and adjusting the pH to 6 to 8, then entering into a second effect evaporator of the MVR for concentration, and separating salt by a centrifugal machine; the combination of the most energy-efficient MVR evaporation technology and chemical treatment is adopted, industrial salt which can be exported can be obtained, COD (Chemical Oxygen Demand) of the wastewater is greatly reduced, the effluent standard can be met after post processing; the COD of condensation water by MVR evaporation is very low and the condensation water can be reused for production, the water consumption of production is lowered, and the production cost is saved.

Owner:KEMAI CHEM

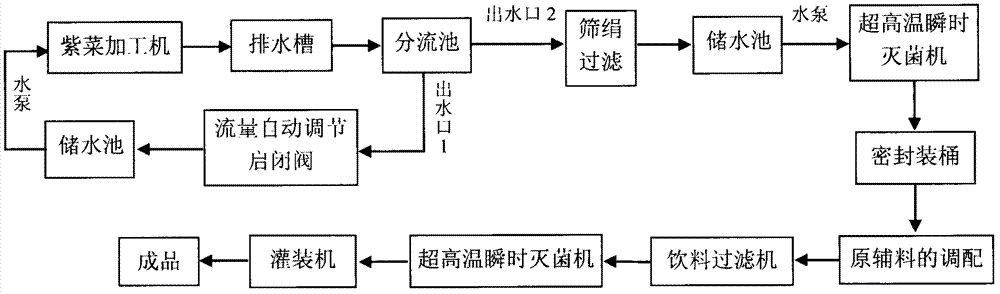

Method for recycling water in laver processing

InactiveCN102948830AAvoid pollutionReduce production water consumptionClimate change adaptationBioloigcal waste fertilisersReclaimed waterEnvironmental engineering

The invention discloses a method for recycling water in laver processing. The method includes a process of recycling the water produced by a laver processing machine, and a process of adopting the recycled water as the raw material to produce beverage. The process of cycling the water produced by the laver processing machine comprises the following steps: draining the water into a flow splitting tank by a draining pipe of the laver processing machine; automatically adjusting a switch valve to be switched on by virtue of the flow in a water outlet when the water in the flow splitting tank is accumulated to be higher than the water outlet; pumping the water to a material inlet of the laver processing machine by a water pump; automatically adjusting the switch valve to be switched off once the water circulating volume reaches a set volume; draining the water from another water outlet; filtering the water, and transferring the water into an ultrahigh-temperature instant sterilizer to sterilize; and then storing the water into a storage tank and sealing after the sterilizing. The process of adopting the recycled water as the raw material to produce beverage comprises the following steps: taking the sterilized circulating water as the raw material; and mixing the sterilized circulating water with auxiliary materials; filtering by a beverage filter; transferring water into the ultrahigh-temperature instant sterilizer to sterilize; and then filling by a filling machine after sterilizing. The laver residues obtained by filtering can be used as feeds or vegetable fertilizers.

Owner:苏州思维德生物科技有限公司

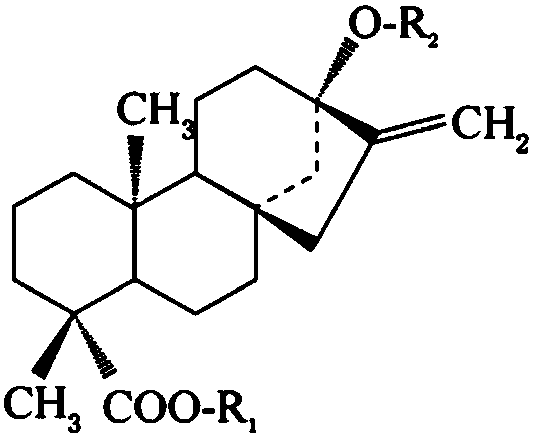

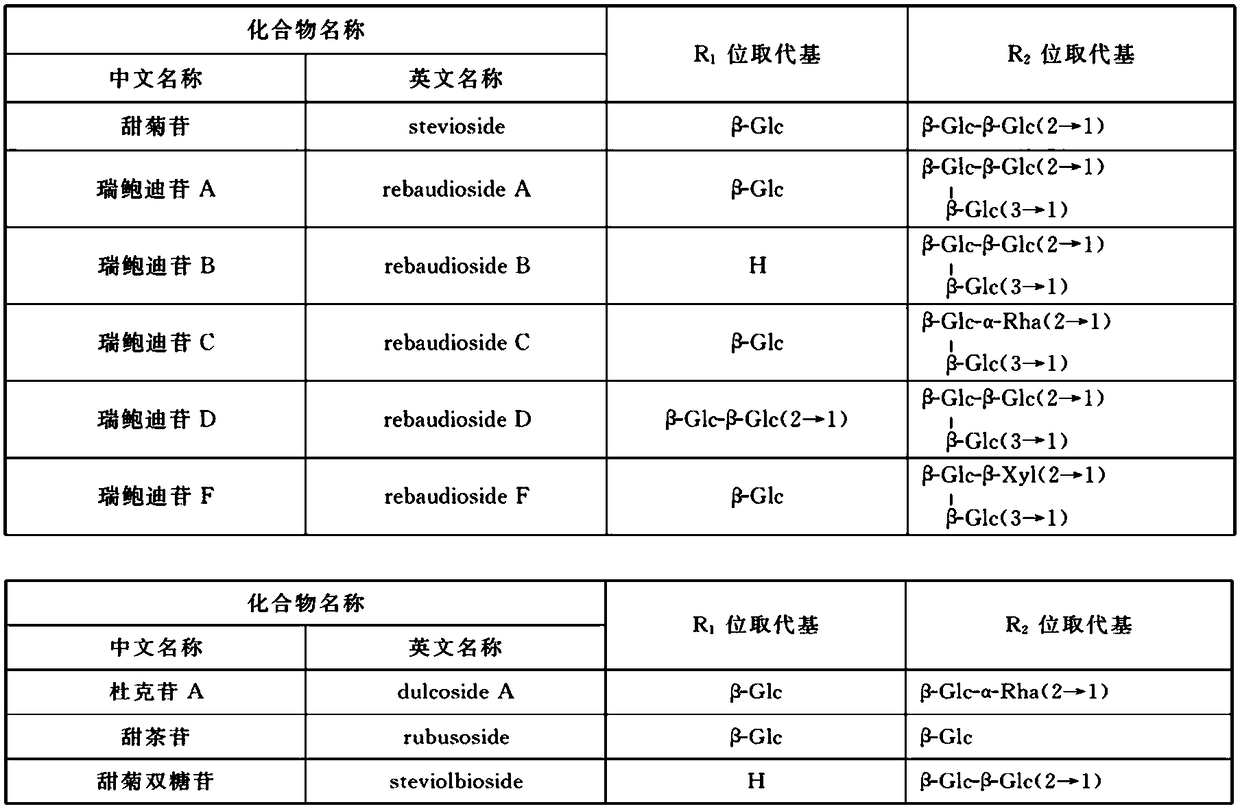

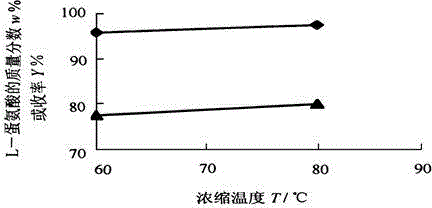

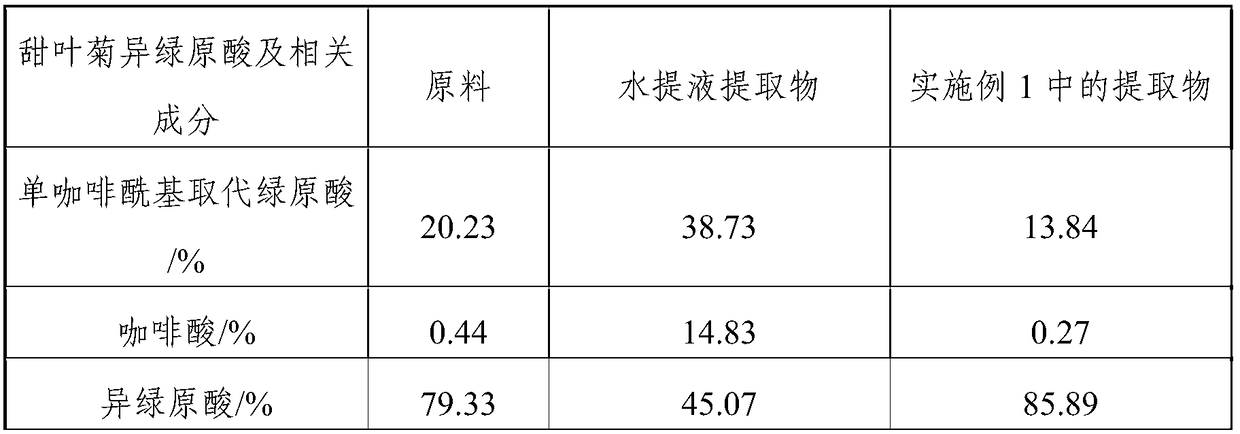

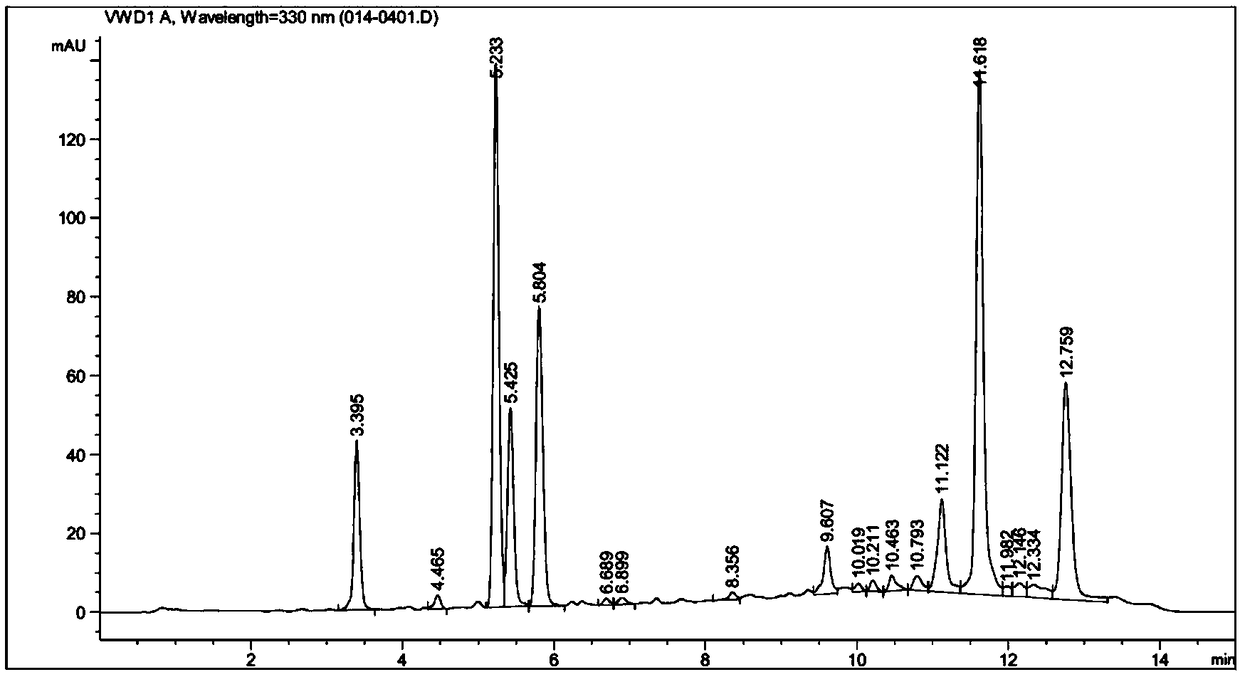

Industrialized utilization method of stevia rebaudiana and chlorogenic acid and stevioside

ActiveCN109265346AAvoid hydrolysisGuaranteed validitySugar derivativesOrganic compound preparationHigh concentrationAlcohol

The invention relates to an industrialized method for extracting chlorogenic acid and stevioside of stevia rebaudiana. The method has the main improvement points that firstly, stevia rebaudiana powderis extracted by a high-concentration alcohol solution; then, extraction liquid is adsorbed by polar adsorption resin subjected to hydroxyl modification; chlorogenic acid type substances are obtained;finally, glycoside resin is used for separation to obtain stevioside. The method provided by the invention has the advantages that the hydrolysis of isochlorogenic acid ingredients in the tevia rebaudiana can be prevented; the effective ingredient content and efficiencies of a stevia rebaudiana chlorogenic acid product can be ensured; the successful separation and extraction of the isochlorogenicacid are realized. The method can also realize the effective separation of the stevioside; the production efficiency is improved; the stevioside quality is improved.

Owner:CHENGUANG BIOTECH GRP CO LTD

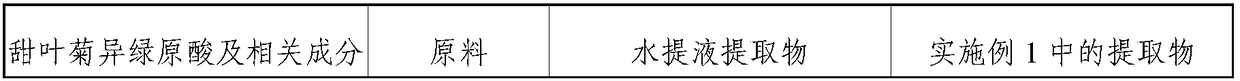

Method for producing organic concentration protein of soybean

InactiveCN101171951AGood for healthNo emissionsProtein composition from vegetable seedsFood preparationAdditive ingredientConcentration gradient

The invention relates to a production method of soybean organic concentrated protein, which comprises crushed soybean pulp obtained after degreasing is performed through a squeezing method. The soybean pulp is immersed in water, and dairy salt and soda powder are added simultaneously during the immersion; the solution is segregated from the mixture of powder and water; the solution is put into a concentration gradient regulator or a double-effect evaporator to perform concentration; the concentrated solution is sterilized through high temperature; isotrope is performed, and the solution is dried, to obtain light yellow albumen powder grain with protein level of 60 to 70 percent. The invention has the positive effects that the raw material is organic soybean pulp squeezed through a machine, acid, alkali and alcohol are not used during the production process, to ensure that the product is green and organic, the natural taste is maintained, the invention contains all the protein of 2S, 7S, 11S and 15S and oligosaccharide, the isoflavone content in the product is five times higher than the prior art, and the lecithine content is enhanced by nearly 50 percent. The natural nutrition ingredient of the soybean is maintained to the maximum degree. The production water consumption is small, the water resource is saved, no waste water is drained, and the environment is not polluted. The production technology is simple, and the production cost is low.

Owner:JILIN GUANGTAI BIOLOGICAL PROTEIN TECH

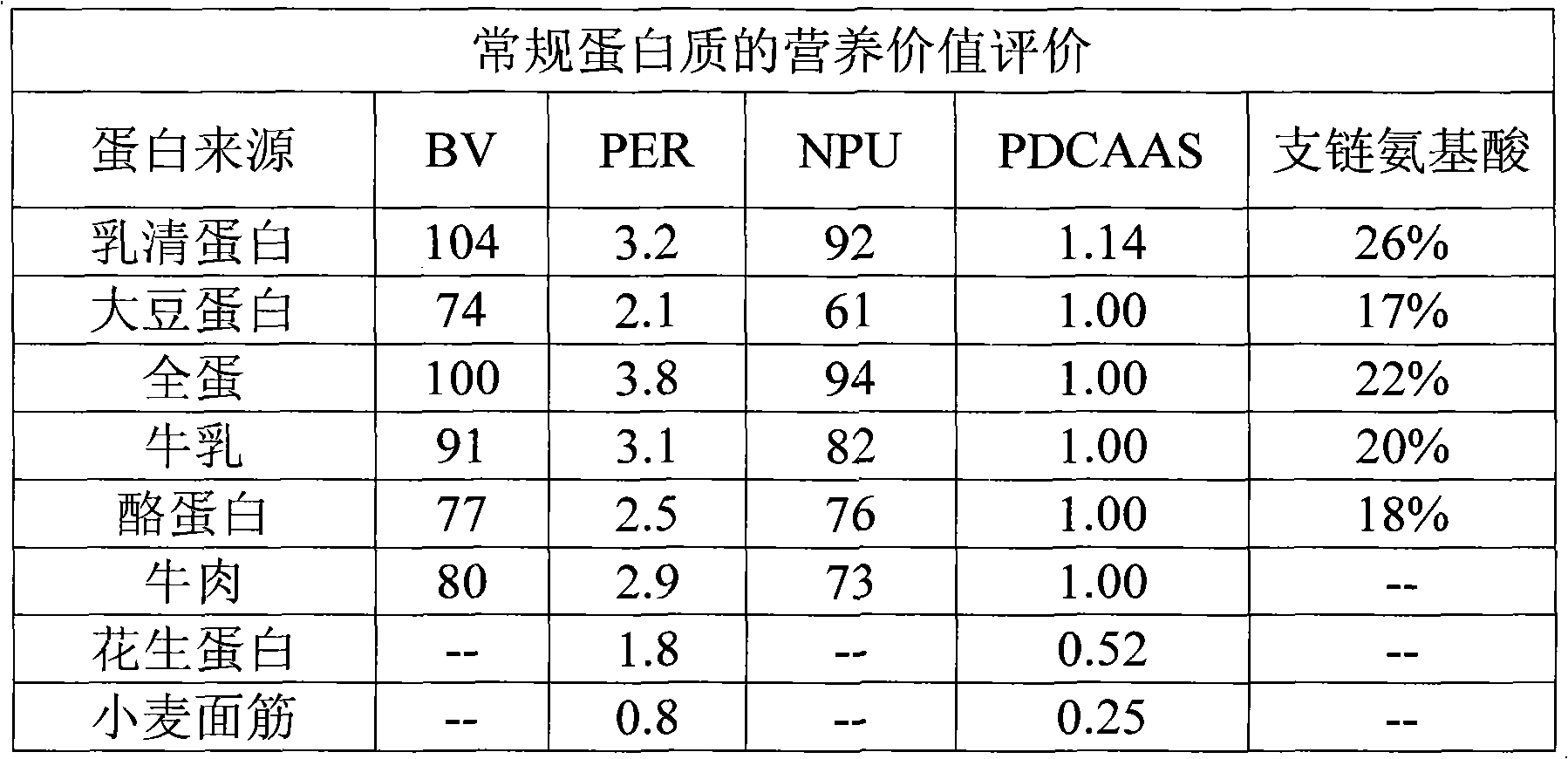

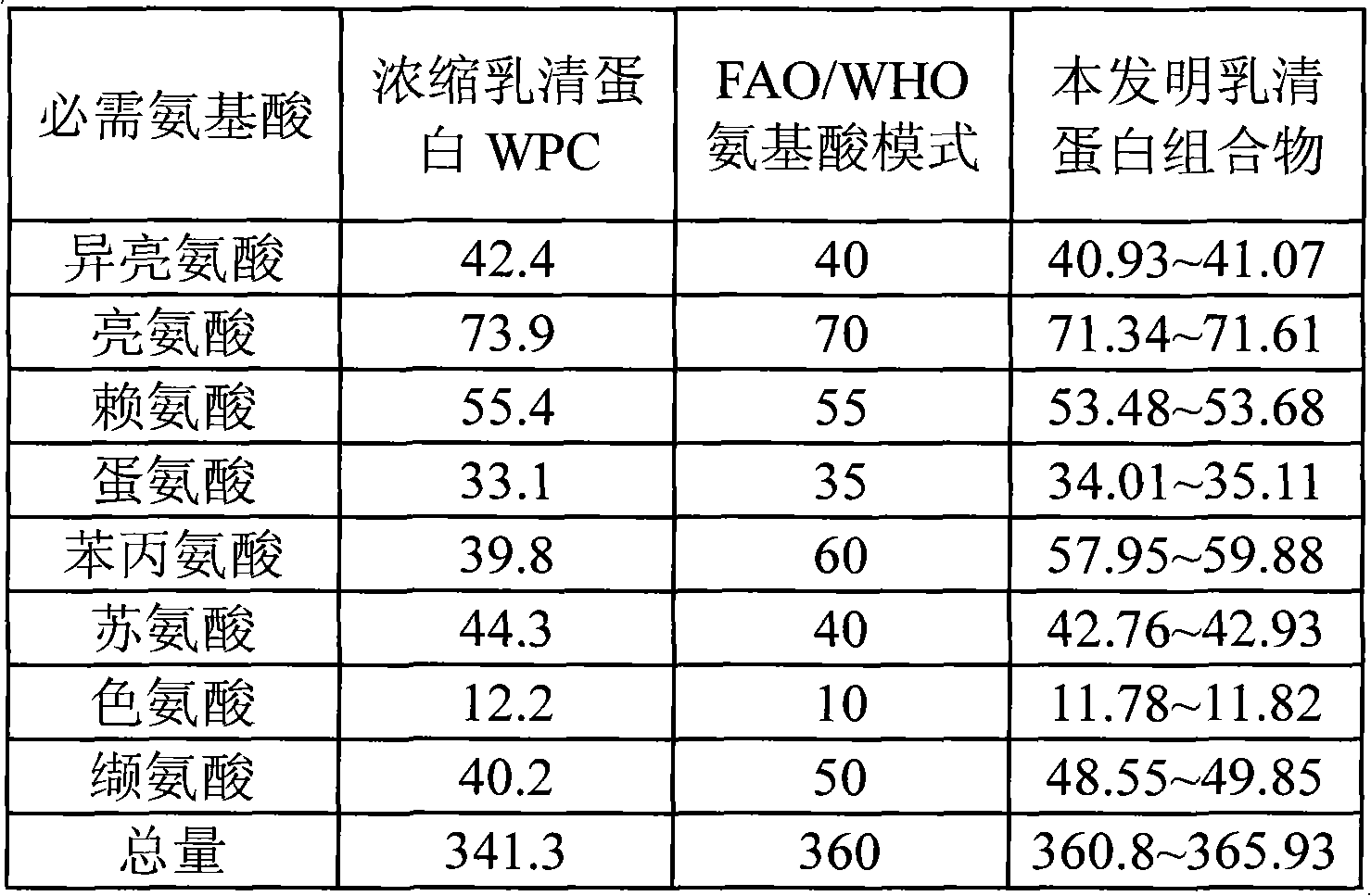

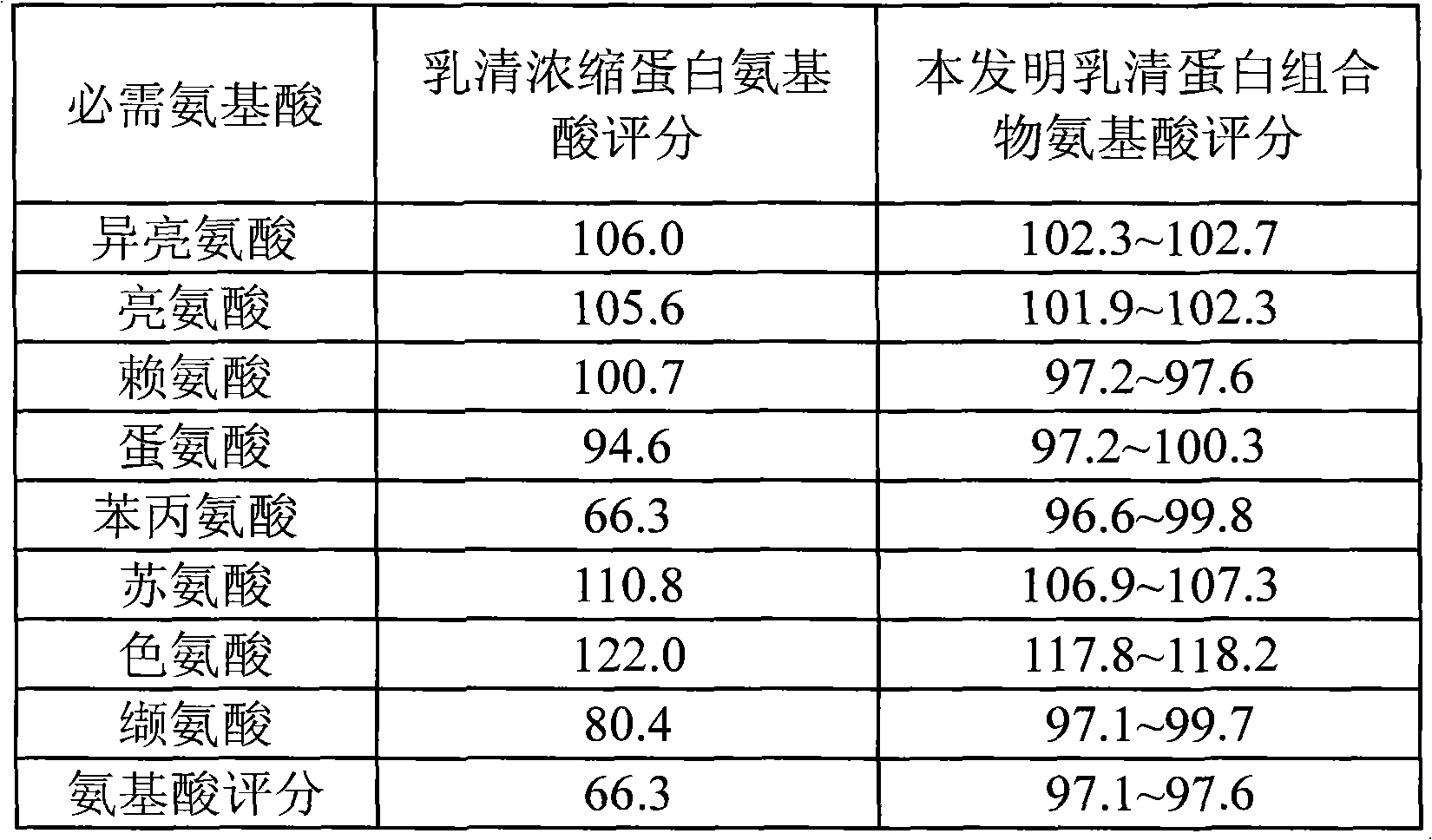

Whey protein composition and preparation method thereof

ActiveCN102599402AGood brewabilityOvercome the disadvantage of poor brewabilityFood preparationAdditive ingredientWhey protein isolate

The invention discloses a whey protein composition and a preparation method thereof. The formula of the whey protein composition comprises the following components in percentage by mass based on the total weight of the whey protein composition: 40 to 90 percent of whey protein concentrate and / or whey protein isolate, 0 to 50 percent of carbohydrate, 0.6 to 1.8 percent of phenylalanine, 0.3 to 0.9percent of valine, 0.06 to 0.2 percent of methionine, 3 to 6 percent of beta-cyclodextrin, 0.5 to 1.0 percent of sodium carboxymethylcellulose and 0.2 to 0.6 percent of soybean phospholipid. The preparation method comprises the following steps of: (1) mixing the phenylalanine, the valine, the methionine, the beta-cyclodextrin, the sodium carboxymethylcellulose and water to obtain an aqueous solution, and drying to obtain an amino acid mixture; (2) mixing the whey protein concentrate and / or the whey protein isolate, the carbohydrate and the amino acid mixture to obtain a dry mixture; and (3) granulating the dry mixture obtained in the (2) and the soybean phospholipid, and thus obtaining the whey protein composition. The whey protein composition has good instant property, high nutritional value and good flavor and mouthfeel.

Owner:BRIGHT DAIRY & FOOD CO LTD

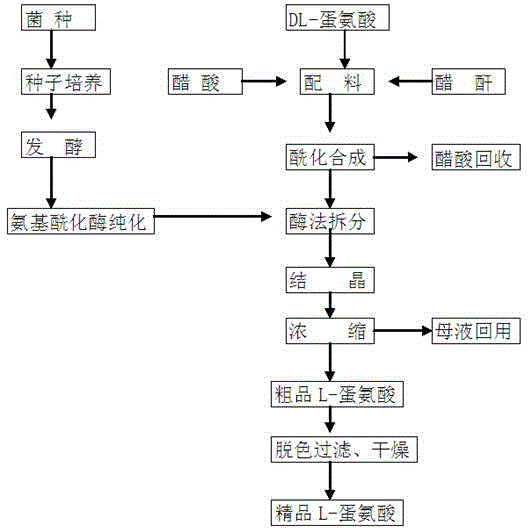

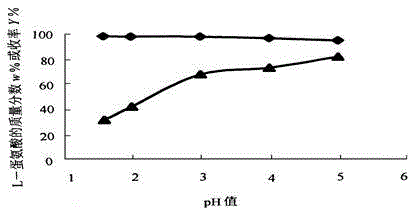

Production technology of L-methionine

InactiveCN104152524AThe fermentation process is simpleSimple extraction processFermentationChemical synthesisDL-methionine

The invention relates to the technical field of methionine, and particularly discloses a production technology of L-methionine. According to the production technology of L-methionine, L-methionine adopts DL-methionine as a raw material and is prepared through biological enzyme resolution; and stereospecificity of amino-acylase is L type, amino-acylase can perform resolution on chemosynthetic N-acetylDL-amino acid, and L-methionine is prepared through a series of biochemical treatment according to the characteristic of amino-acylase. According to the invention, a non-aqueous solution acylation technology is adopted, acylation yield is increased to 126%-128%, the enzymatic resolution period is shortened to 35 hours, a fluxing agent is recycled, sewage discharge is reduced, and the total yield of L-methionine production reaches 82%.

Owner:SHANDONG YANGCHENG BIOLOGY TECH CO LTD

Oxygen-free cooling and residual heat recovering method for magnetizing-roasted iron ore product

InactiveCN103789536AChange the water cooling processReduce pollutionIncreasing energy efficiencyMagnetic separationIronstoneGranularity

The invention relates to the technical field of metallurgy, in particular to an oxygen-free cooling and residual heat recovering method for a magnetizing-roasted iron ore product. The method comprises the following steps: feeding a magnetizing-roasted high-temperature material being 800-850 DEG C and 8-25 millimeters in granularity from the upper part of a vertical cooler; introducing blast furnace gas of which the CO or H2 volume content is not greater than 30 percent from the lower part of the vertical cooler, and controlling the flow rate of the high blast coal gas at 0.8-1.5 m / s; performing heat exchange between the high-temperature material and the blast coal gas in the vertical cooler during inverse flow, wherein the temperature of the high-temperature material is lowered below 200 DEG C, and the temperature of the blast coal gas is raised to 700-750 DEG C. The magnetizing-roasted high-temperature material undergoes secondary oxidation in a cooling process, and can undergo secondary micro-reduction in the cooling process in the cooler, so that the quality of the magnetizing-roasted iron ore product is improved. Meanwhile, the over-reduction of the material is prevented, and cyclic utilization of residual heat is realized.

Owner:JIUQUAN IRON & STEEL GRP

Industrial utilization method for stevia, stevioside and chlorogenic acid

ActiveCN109293712AAvoid hydrolysisGuaranteed validitySugar derivativesOrganic compound preparationGlycosideHigh concentration

The invention relates to an industrialization method for comprehensive utilization of stevia. The method is mainly characterized in that the stevia is extracted with a high-concentration alcohol solution, then the obtained extract is purified by using an organic solvent, and the extract is adjusted to be alkaline according to the acidic characteristic of chlorogenic acid to make the chlorogenic acid form a salt and have an increased polarity in order to realize effective separation of the chlorogenic acid and a glucoside component in the adsorption link. The method allows the high-quality stevioside and chlorogenic acid to be obtained, significantly improves the comprehensive utilization rate of stevia, reduces the waste of natural stevia resources, reduces the resource consumption in theproduction process, reduces waste discharge, is a high-benefit green production process, and can greatly advance the industry.

Owner:CHENGUANG BIOTECH GRP CO LTD

Industrial method for synchronously preparing stevia rebaudiana chlorogenic acid and stevioside

PendingCN109438241AAvoid hydrolysisGuaranteed validitySugar derivativesOrganic compound preparationWater insolubleOrganic layer

The invention relates to an industrial method for synchronously preparing stevia rebaudiana chlorogenic acid and stevioside. The industrial method includes carrying out alcohol extraction on stevia rebaudiana which is used as a raw material, and then adjusting feed liquid states to allow chlorogenic acid to be in free molecular states; carrying out extraction separation by water-insoluble moderate-polarity organic solvents; enriching the stevia rebaudiana chlorogenic acid on organic layers; enriching the stevioside on water layers. Compared with the traditional water extraction processes, theindustrial method has the advantages that chlorogenic acid components in the stevia rebaudiana can be prevented from being hydrolyzed, so that the contents and effects of effective components in stevia rebaudiana chlorogenic acid products can be guaranteed; effective separation can be carried out on the premise that the quality and the production efficiency of stevioside products are unaffected, the production efficiency can be greatly improved, and the proportion of isochlorogenic acid in the obtained products is close to the proportion of isochlorogenic acid in the raw material; production water consumption can be reduced to a great extent, discharge of sewage and flocculation residues can be decreased, accordingly, the industrial method is a green production process with high benefits,and the progress of the industry can be promoted to a great extent.

Owner:CHENGUANG BIOTECH GRP CO LTD

Method for producing biological organic fertilizer from wheat straw

InactiveCN104355709AShorten composting timeReduce production water consumptionBio-organic fraction processingOrganic fertiliser preparationWater contentNutrient

The invention relates to a method for producing a biological organic fertilizer from wheat straw. The method comprises the following steps: crushing the wheat straw to be less than 50mm; spraying a bacterial liquid onto the crushed wheat straw, uniformly mixing, controlling the water content to be within 70-85% and the pH value to be 7; turning over when the temperature of the material is risen to be 50 DEG C, and controlling the fermentation temperature to be 50-70 DEG C and the fermentation time to be 5-15 days; when the compost size of the fertilizer is collapsed by 1 / 3-1 / 2 at the final fermentation point, drying the fertilizer in air, so as to obtain the biological organic fertilizer. As the bacterial liquid is used in biological organic fertilizer fermentation production, the composting time is shortened, the water amount for production is reduced, no toxicity, harm or odor is generated, the environment is not polluted, the nutrients can be maintained, the content of organic matters in the fertilizer is increased, and the quality of the fertilizer is improved.

Owner:重庆市盛馨种业有限公司

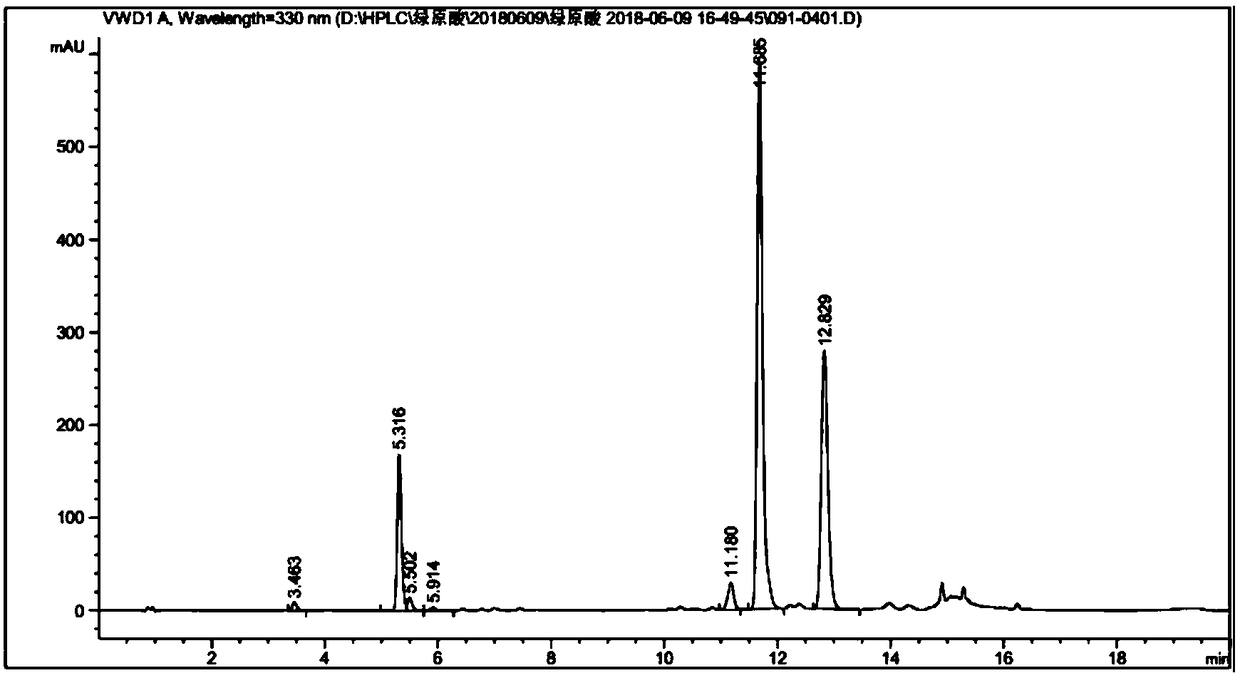

Nitro-cotton cotton pulp dewatering method

The invention discloses a nitro-cotton cotton pulp dewatering method, relates to the technical field of nitro-cotton production, and provides a nitro-cotton cotton pulp dewatering method in which the nitro-cotton loss amount is little during dewatering. The nitro-cotton cotton pulp dewatering method comprises the following steps that 1, heavy impurities and iron chips in cotton pulp are removed; 2, the cotton pulp concentration is adjusted by adopting a concentrator to enable the concentration of cotton materials in the cotton pulp to be increased to 8%-15%; 3, the cotton pulp is conveyed to a horizontal sedimentation centrifuge; 4, the horizontal sedimentation centrifuge is started to perform solid-liquid separation on the nitro-cotton cotton pulp, and the working parameters of the horizontal sedimentation centrifuge are as followed: the rotating speed of a main engine ranges from 2000 r / min to 2500 r / min, the differential speed is 20 r / min, and the internal circle diameter of a water fender is 179 mm. According to the nitro-cotton cotton pulp dewatering method, it can be guaranteed that the wastewater solid content of a nitro-cotton product with the very small particle size is smaller than or equal to 2%o after dewatering is performed, and compared with an existing dewatering technology, the wastewater solid content is significantly decreased, and the product yield is increased.

Owner:SICHUAN NITROCELLULOSE CORP

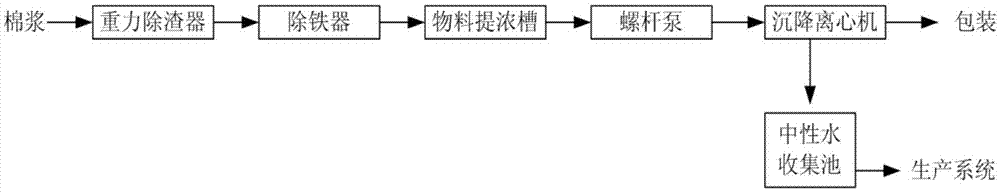

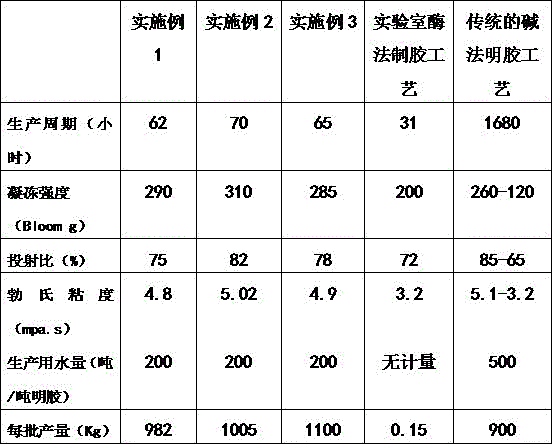

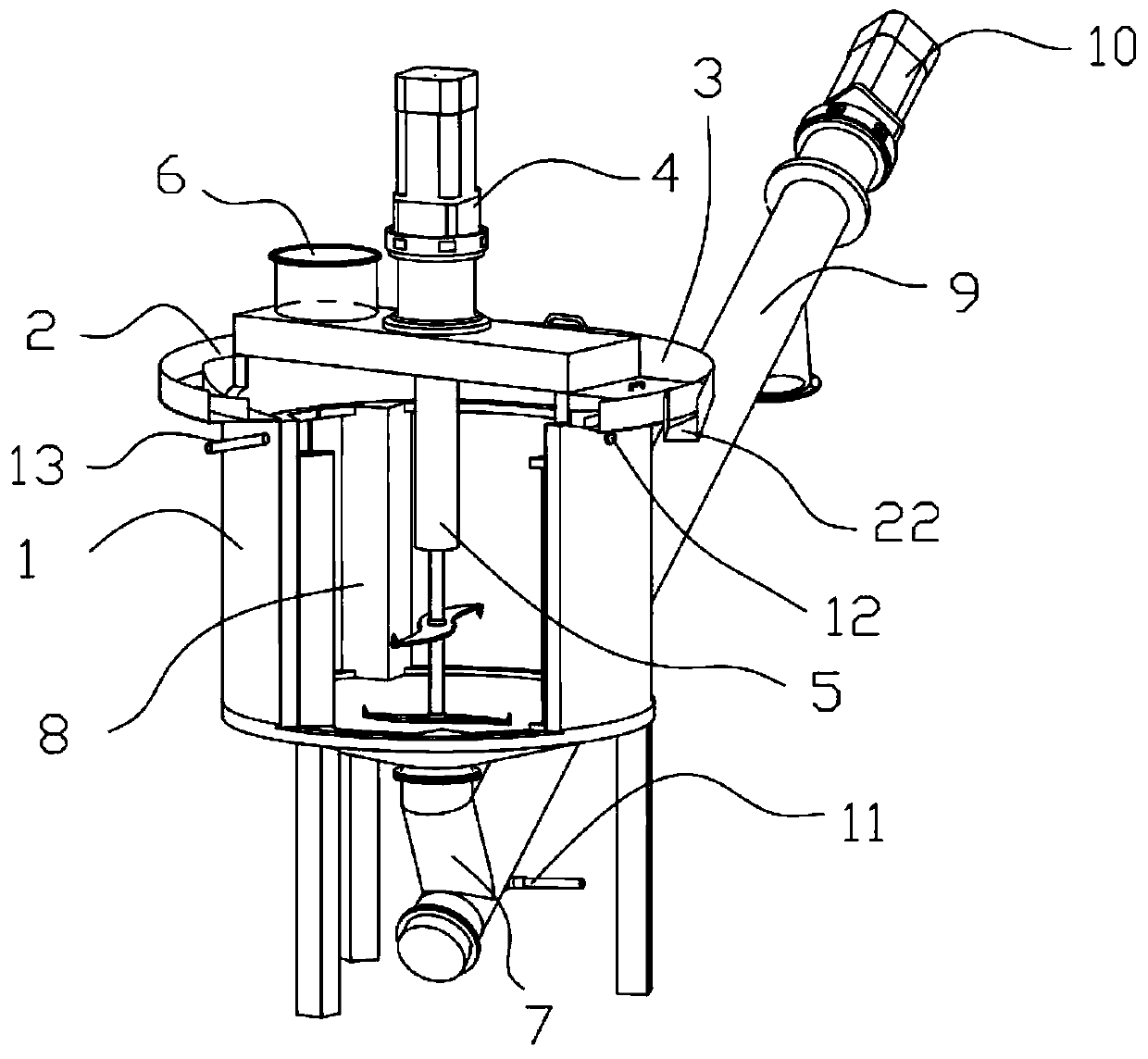

Process for enzymatic preparation of gelatin

The invention provides a process for enzymatic preparation of gelatin. The process comprises steps of crushing bone grains, conducting acid pickling, extracting gel, filtering the gel, concentrating the gel and sterilizing the gel, wherein the step of acid pickling is implemented by the following operations: mixing a bone grain raw material with water according to a weight ratio of 1 to (1-5), controlling a pH value at 1-2.5, conducting soaking for 6-10h, removing a liquid phase by virtue of centrifugal separation, and collecting solid materials settled on a rotary drum wall. The process provided by the invention, compared with a conventional gelatin process by virtue of an alkaline method, can shorten a production cycle, greatly improve efficiency and improve the quality stability of the gelatin.

Owner:NINGXIA XINHAOYUAN BIOLOGICAL POLYTRON TECH INC

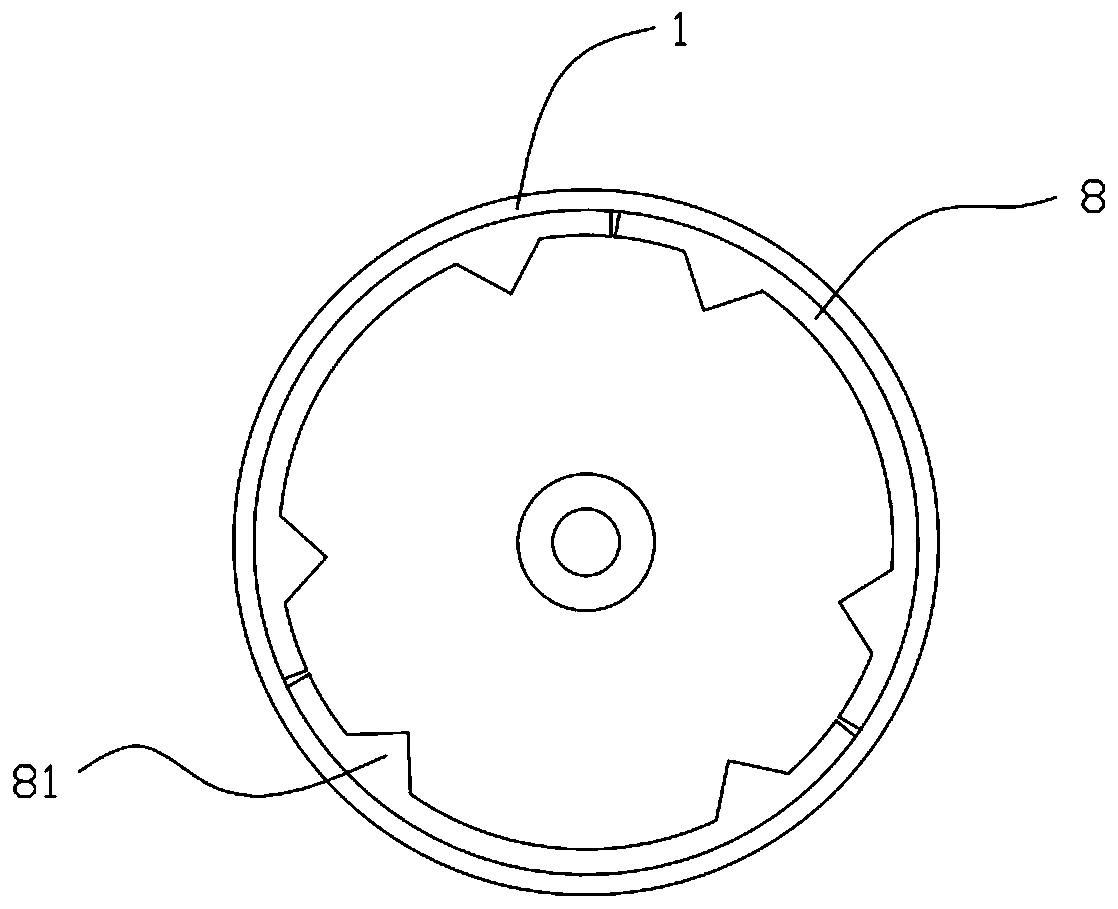

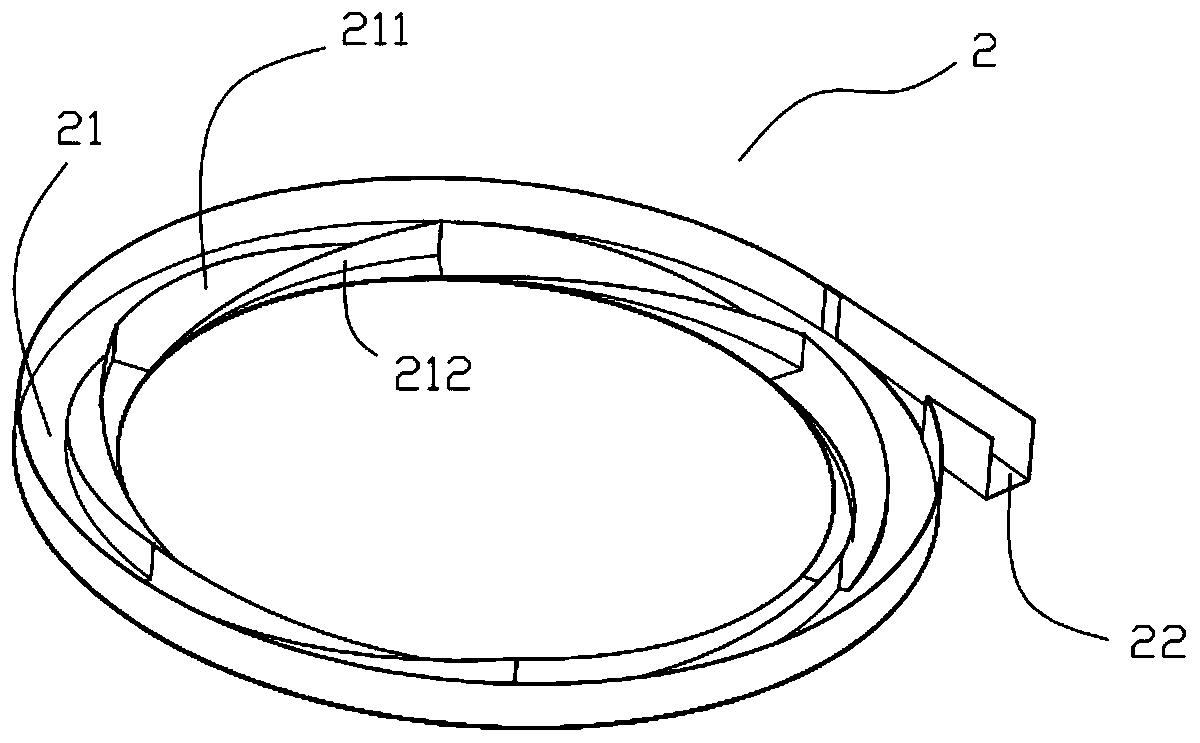

Eggshell membrane separation device, method and production line

The invention discloses an eggshell membrane separation device, method and production line. The eggshell membrane separation device includes a shell, a drainage plate, an upper cover plate and a mixing motor. The drainage plate is provided with a diversion groove and a collecting groove, the diversion groove communicates with the collecting groove, the output end of the mixing motor is connected with a mixing paddle, and the mixing paddle is provided with a first large blade and a second small blade; and the shell is further internally provided with a plurality of arc baffles, the baffles aremovably attached to the inner wall of the shell, and each baffle is provided with one or more bulges. Under the combined action of mechanical agitation, shear breaking and physical water separation ofthe device, the cleaning of eggshell membranes and the high-efficiency continuous automatic separation discharging are realized simultaneously. By using the separation method, device and production line, the purity of the eggshell membranes obtained by separation can reach up to 97% or more, and moreover, by additionally arranging a recovery and purification water pool behind an egg membrane collection device, production water can be recycled. The separation method has the significant advantages of convenient operation, high separation efficiency, high purity of the separated egg membranes, continuous and automatic operation and cost saving.

Owner:湖北神地农业科贸有限公司 +2

Method for preparing feldspar powder concentrate by mineral separation of aeolian sand in desert

ActiveCN101885489BReduce production water consumptionReduce manufacturing costSilicon compoundsIntermediate stageEnergy consumption

The invention belongs to an industrial utilization method of aeolian sand in desert, in particular to a method for preparing feldspar powder concentrate by mineral separation of aeolian sand in desert. The method comprises an early-stage ferrum-removal process, a middle-stage feldspar flotation separation process and a later-stage ferrum-removal process. The early-stage ferrum-removal process comprises the following specific steps: firstly, carrying out dry magnetic separation on the aeolian sand in the desert; carrying out reselection and separation on the concentrate obtained after dry magnetic separation; carrying out powerful scrubbing and sizing-desliming on the concentrate obtained after reselection and separation; and carrying out wet magnetic separation to obtain the ferrum-removal concentrate for the middle-stage feldspar flotation separation process, and carrying out the later-stage ferrum-removal process on the feldspar mineral aggregate obtained in the middle-stage feldspar flotation separation process to finally obtain the feldspar powder concentrate. The processes of the invention have the advantages of water conservation, reduced energy consumption and low cost, andcan fully utilize the existing aeolian sand resources to produce the high-quality feldspar powder concentrate.

Owner:CHANGSHA RES INST OF MINING & METALLURGY +1

Comprehensive treatment method for recycling waste calcium water and waste acid obtained through algin production

ActiveCN105481136AOvercoming the difficulty of subsidenceOvercome costsMultistage water/sewage treatmentSalt-wastingCalcification

The invention belongs to the technical field of alga chemical production and relates to a comprehensive treatment method for recycling waste calcium water and waste acid obtained through algin production. The comprehensive treatment method comprises 1, removing suspended solids in waste calcium water, 2, adding a calcium removal agent into the waste calcium water to remove calcium and carrying out settlement, 3, removing impurities in the supernatant, directly utilizing the supernatant as return water, adding calcium carbonate into the waste acid for a reaction so that a calcium chloride solution is obtained and adding hydrochloric acid into the calcium chloride solution so that a calcium chloride mass concentration is at least 12%, and 4, filtering the calcium chloride solution and directly utilizing the filtered calcium chloride solution in an algin solution calcification process in algin production. The comprehensive treatment method solves the problem that the existing waste water treatment process has high settlement difficulty and a high cost and produces a large amount of calcium salt wastes. The comprehensive treatment method realizes comprehensive recycle of algin processing waste water.

Owner:SHANDONG JIEJING GROUP CORP

A device and method for realizing reuse of printing and dyeing wastewater and recovery of dyestuffs

ActiveCN104609605BAchieve retentionAchieve reuseMultistage water/sewage treatmentSeparation technologyHigh pressure

The invention relates to a printing and dyeing wastewater reuse, and particularly relates to a device and a method for printing and dyeing wastewater water-soluble dye recovery on the basis of a membrane separation technology. The device comprises a raw water booster pump, a self-cleaning filter, a precise filter, an ultrafiltration membrane assembly, an ultrafiltration backwash pump, an ultrafiltration water tank, a high-pressure pump, a nanofiltration membrane assembly, and a reducer and scale inhibitor pouring system which are communicated with a wastewater collection pool. The method comprises the steps of draining the dyed wastewater to the wastewater collection pool and pumping the dyed wastewater in the self-cleaning filter through the raw water booster pump to remove large-particle suspended matters and impurities, then entering the wastewater into the precise filter to remove the remainder suspended matters, then entering the wastewater into an ultrafiltration membrane to remove bacteria, colloids and macromolecular organic compounds, finally pumping the wastewater in a nanofiltration membrane device through the high-pressure pump to remove micromolecular organic compounds and divalent ions, thereby producing high-quality reclaimed water and simultaneously intercepting and recovering most of activated dye molecules.

Owner:DALIAN UNIV OF TECH

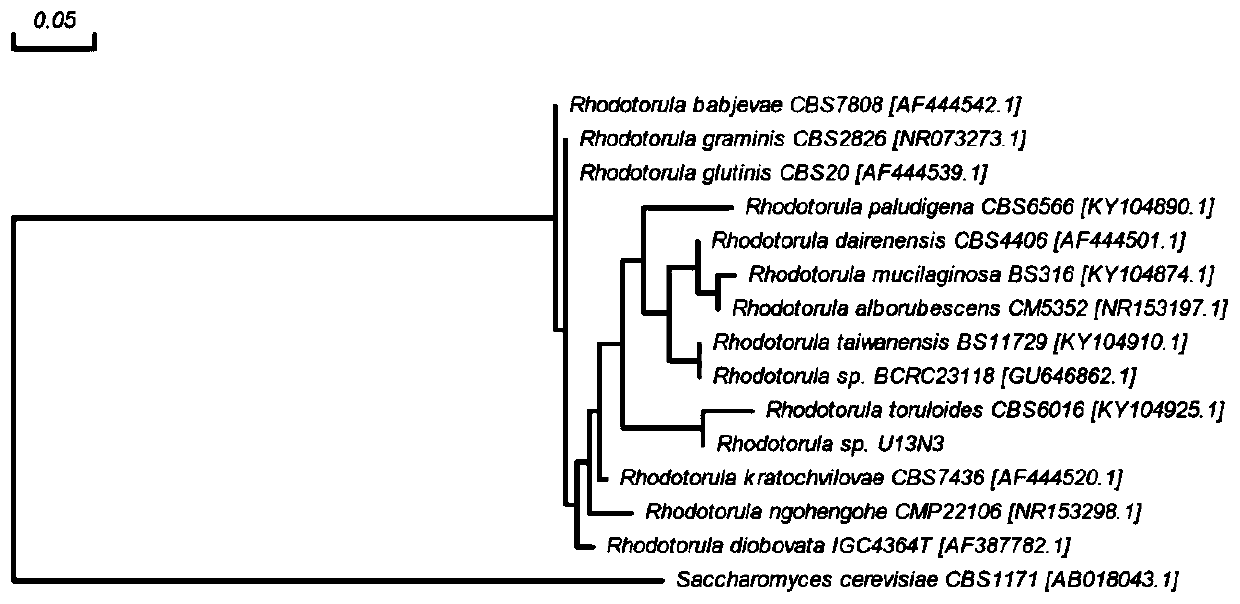

Rhodotorula, culture method thereof and application of rhodotorula in production of biolipid

ActiveCN110885765ALow pigment contentImprove qualityFungiMicroorganism based processesBiotechnologyRhodotorula

The invention discloses rhodotorula, a culture method thereof and an application of the rhodotorula in production of biolipid. The rhodotorula U13N3 disclosed by the invention is preserved in China Center for Type Culture Collection, and the preservation number is CCTCC NO: M 2019503. The rhodotorula U13N3 is characterized in that the carotene production capacity is lost, and bacterial colonies are off-white on a yeast extract-peptone-glucose-agar culture medium. The rhodotorula U13N3 can be fermented by utilizing various carbon sources, and when glycerol is used as a carbon source to be cultured at 37 DEG C, the intracellular grease content can reach 65% of the dry weight of thalli. The rhodotorula U13N3 is wide in environmental adaptability, can utilize various cheap carbon sources to produce biolipid at high yield, does not contain pigments in cells, is beneficial to reducing the impurity content during grease extraction and improving the grease quality, and has a good application prospect.

Owner:NANJING UNIV OF SCI & TECH

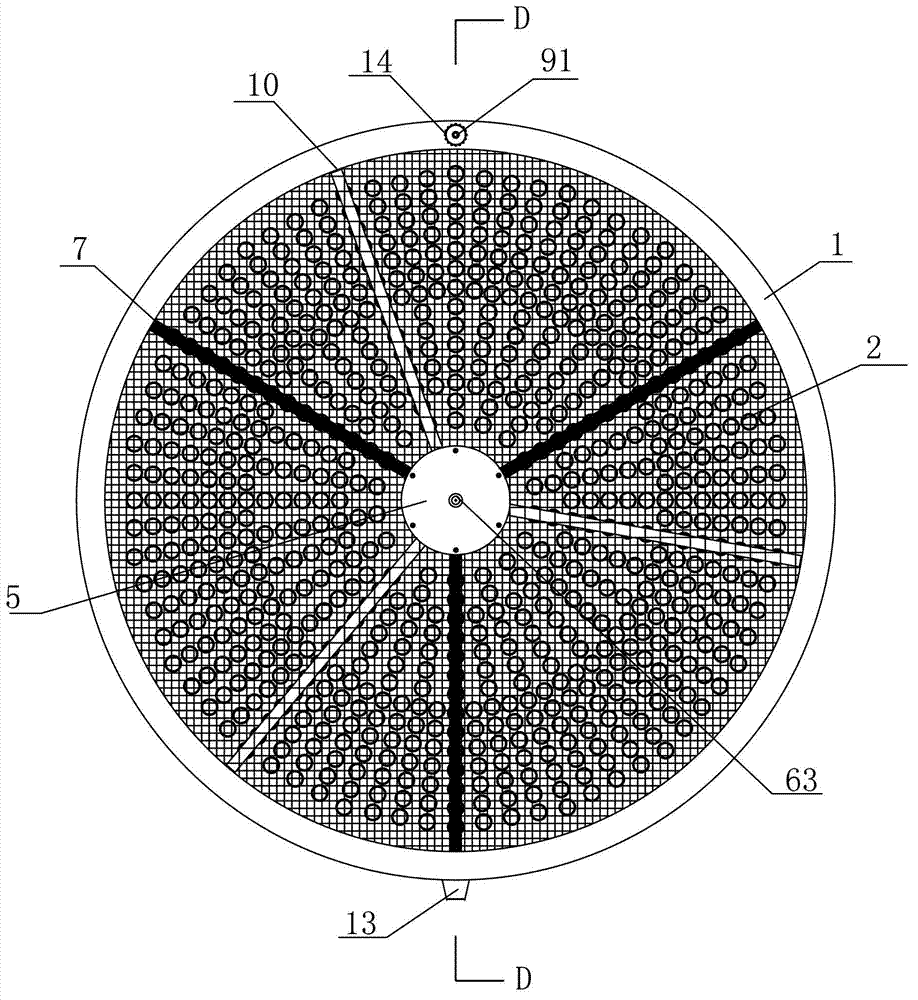

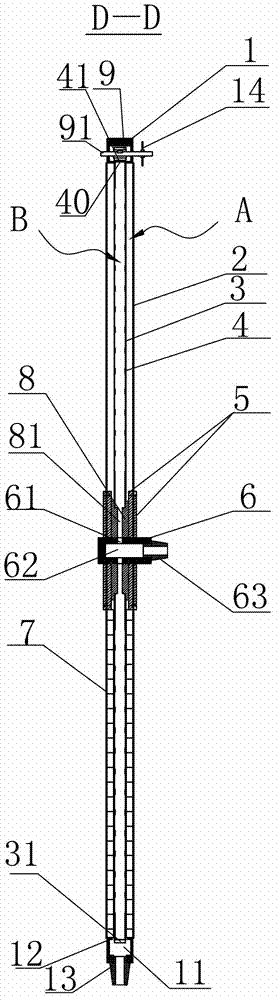

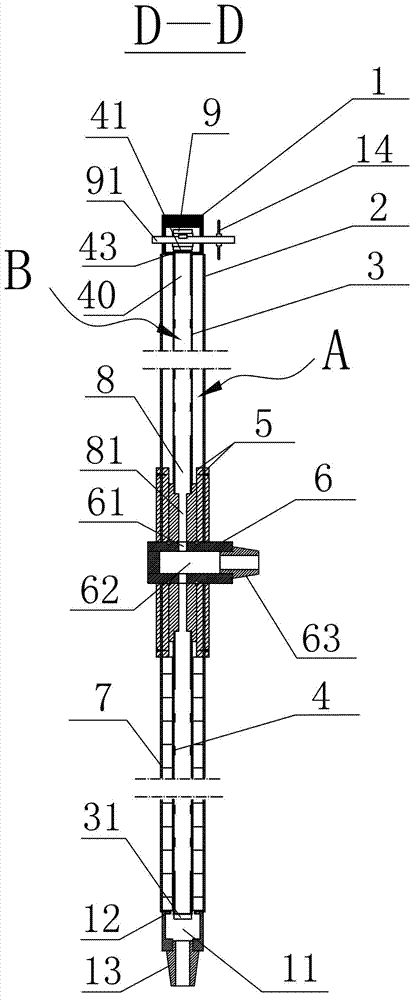

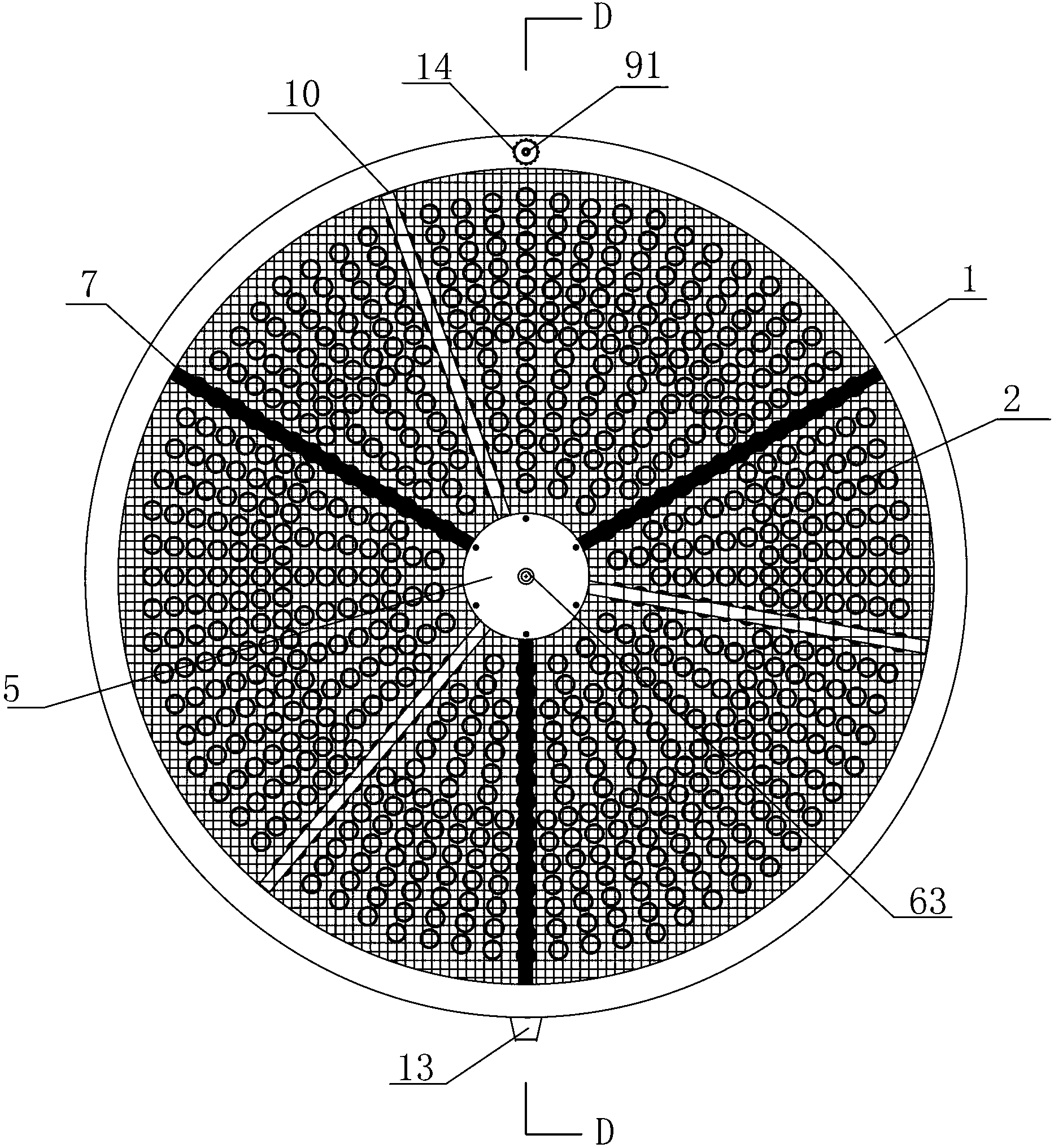

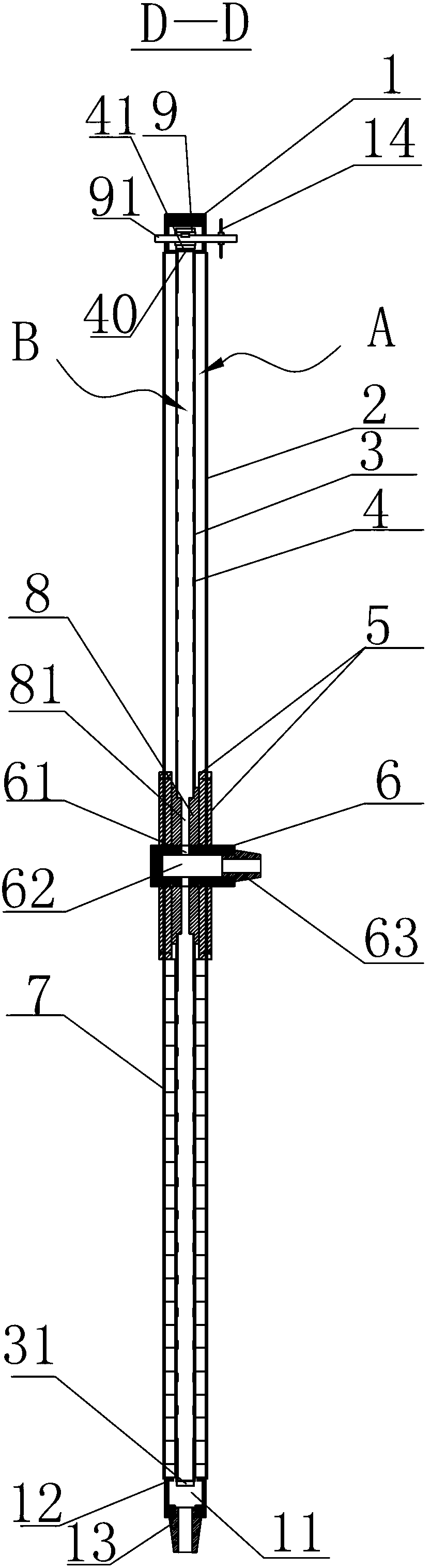

Rotating disc type micro-grid assembly for backwash-free dynamic membrane

ActiveCN102923849AStable generationMetabolic stabilitySustainable biological treatmentBiological water/sewage treatmentUltrasound attenuationCircular disc

The invention relates to a rotating disc type micro-grid assembly for a backwash-free dynamic membrane. The rotating disc type micro-grid assembly comprises a circular-disc shaped filter tank, wherein the interior of the filter tank is a micro-grid cavity; the rotating disc type micro-grid assembly is characterized in that a micro-grid base material is an outer micro-grid; the filter tank is an outer filter tank; a central water outlet pipe perpendicular to a disc surface of the outer filter tank is arranged on a circle center part of the outer filter tank; a water outlet rotating disc which is matched with the central water outlet pipe in a sliding mode is sleeved on the central water outlet pipe; clamping discs which are fixedly connected with the central water outlet pipe and are fixed on two sides of the outer micro-grid are respectively sleeved on two sides of the water outlet rotating disc; a circular-disc shaped inner filter tank which is connected with the water outlet rotating disc is arranged in the outer filter tank coaxially; teeth are circumferentially arranged outside the inner filter tank; a disturbance water catchment channel is arranged in the outer filter tank; a transmission gear engaged with the teeth are arranged in the outer filter tank; a rotational vibration attenuation brush plate of which a plurality of brush hairs are in contact with the back side of the outer micro-grid is arranged on the inner micro-grid surface which covers the disc surface of a water receiving disc; and a disturbance water drainage nozzle is arranged on the bottom of the outer filter tank. The rotating disc type micro-grid assembly has the advantages of stability in yielding water quality, high flux, high water production rate and simplified facilities.

Owner:清池水环境治理科技发展(天津)有限公司

Rotating disc type micro-grid assembly for backwash-free dynamic membrane

ActiveCN102923849BStable generationMetabolic stabilitySustainable biological treatmentBiological water/sewage treatmentUltrasound attenuationCircular disc

The invention relates to a rotating disc type micro-grid assembly for a backwash-free dynamic membrane. The rotating disc type micro-grid assembly comprises a circular-disc shaped filter tank, wherein the interior of the filter tank is a micro-grid cavity; the rotating disc type micro-grid assembly is characterized in that a micro-grid base material is an outer micro-grid; the filter tank is an outer filter tank; a central water outlet pipe perpendicular to a disc surface of the outer filter tank is arranged on a circle center part of the outer filter tank; a water outlet rotating disc which is matched with the central water outlet pipe in a sliding mode is sleeved on the central water outlet pipe; clamping discs which are fixedly connected with the central water outlet pipe and are fixed on two sides of the outer micro-grid are respectively sleeved on two sides of the water outlet rotating disc; a circular-disc shaped inner filter tank which is connected with the water outlet rotating disc is arranged in the outer filter tank coaxially; teeth are circumferentially arranged outside the inner filter tank; a disturbance water catchment channel is arranged in the outer filter tank; a transmission gear engaged with the teeth are arranged in the outer filter tank; a rotational vibration attenuation brush plate of which a plurality of brush hairs are in contact with the back side of the outer micro-grid is arranged on the inner micro-grid surface which covers the disc surface of a water receiving disc; and a disturbance water drainage nozzle is arranged on the bottom of the outer filter tank. The rotating disc type micro-grid assembly has the advantages of stability in yielding water quality, high flux, high water production rate and simplified facilities.

Owner:清池水环境治理科技发展(天津)有限公司

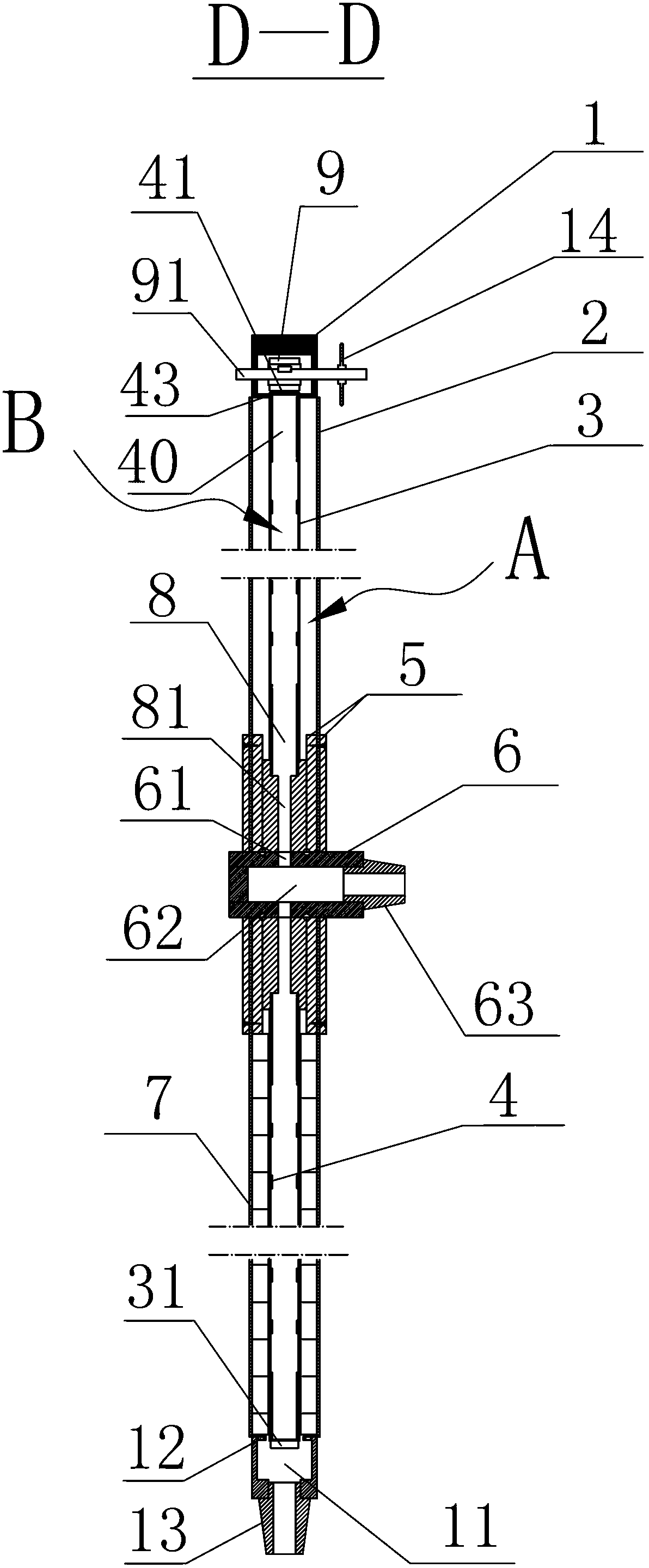

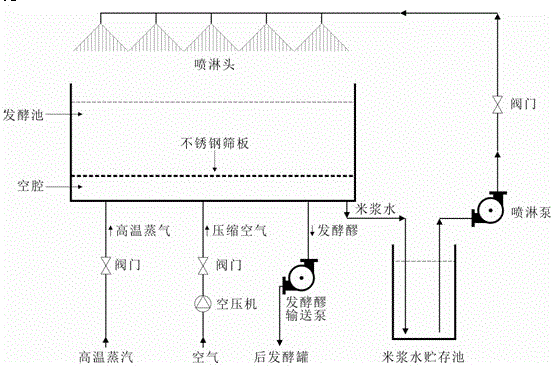

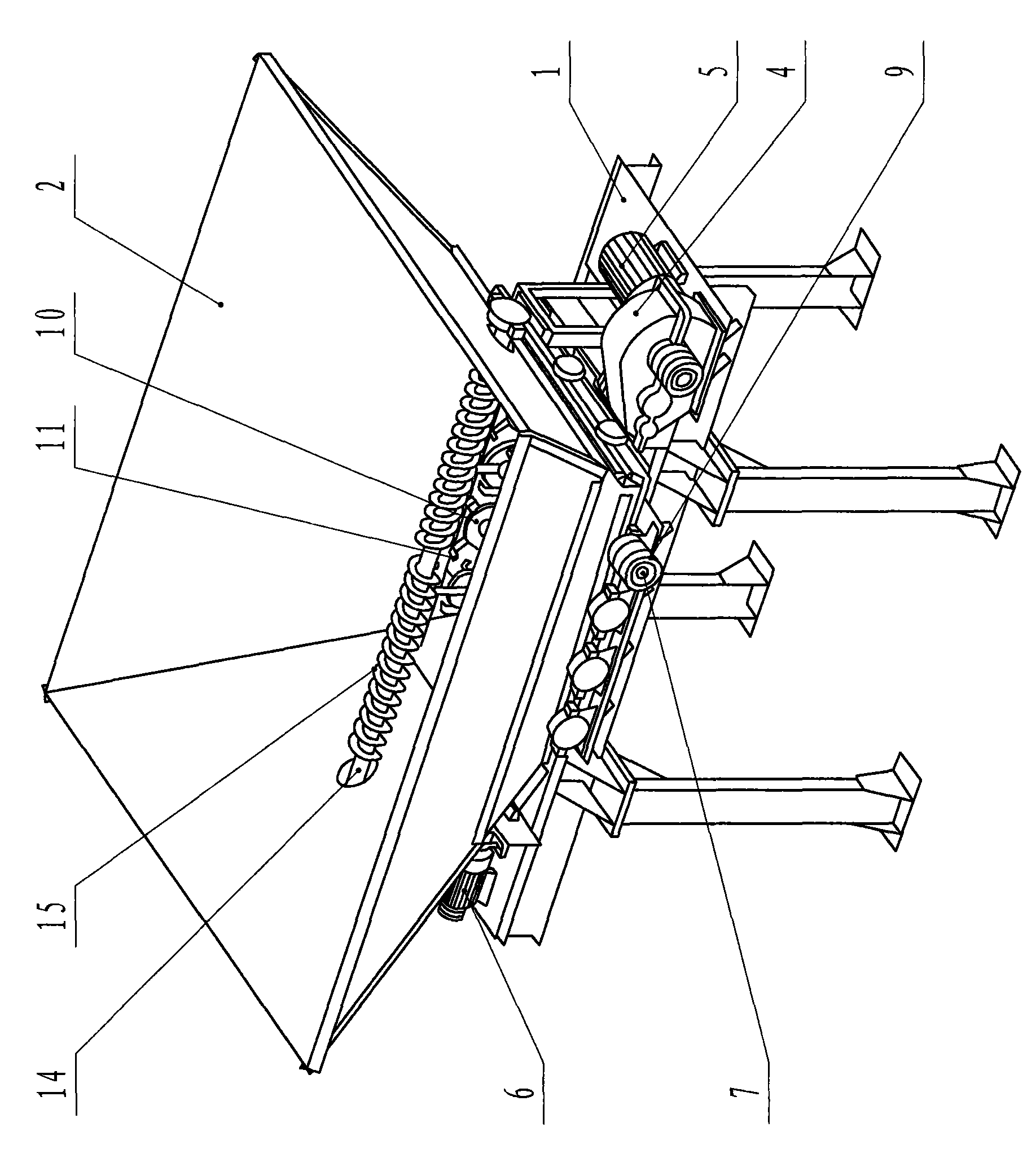

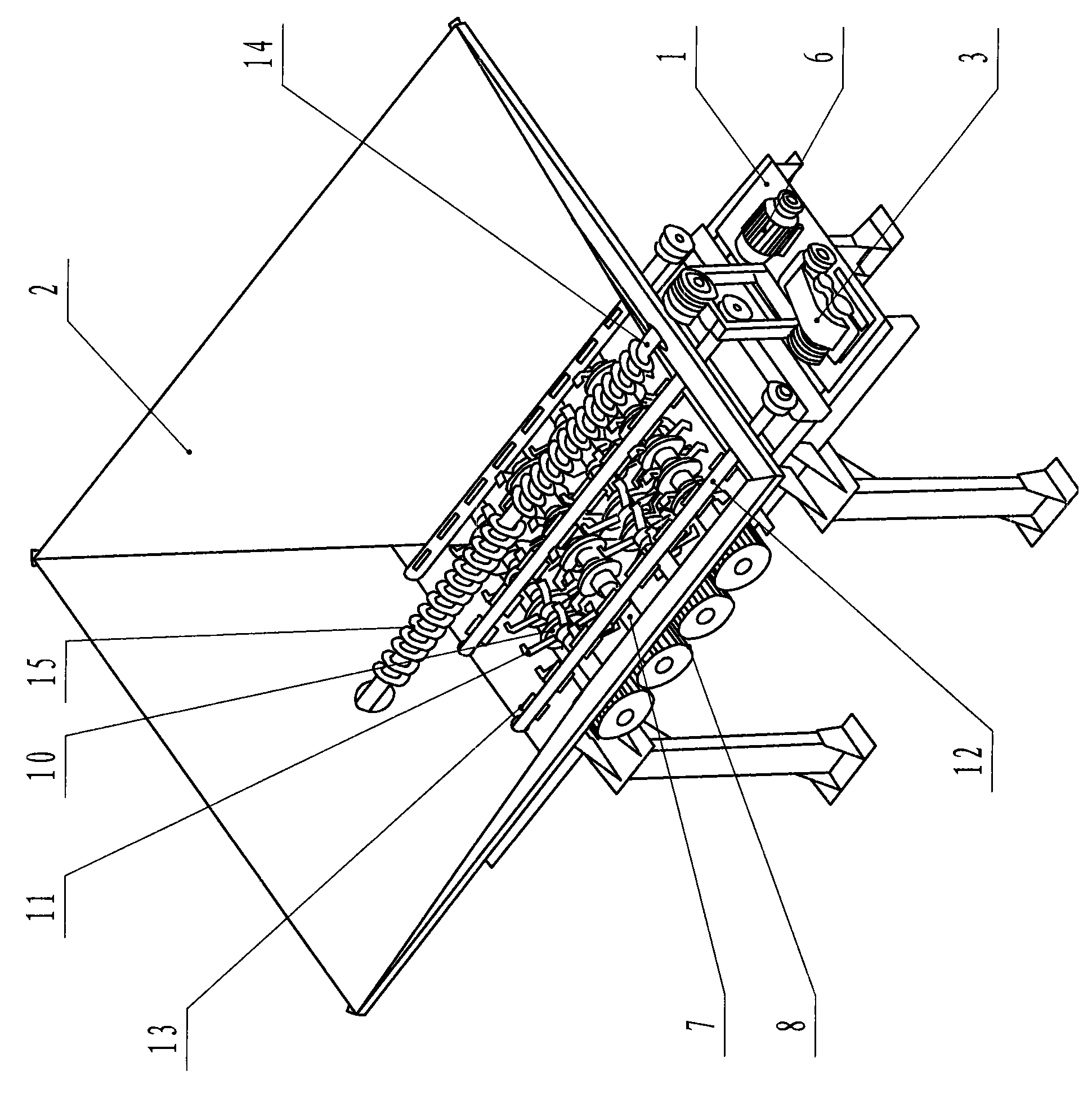

Energy-saving and water-saving yellow wine production device

InactiveCN106635636AEmission reductionReduce production water consumptionAlcoholic beverage preparationWater savingChemical oxygen demand

Traditional yellow wine production relates to extremely complicated technical processes such as rice soaking, rice steaming, cylinder filling, yeast adding, fermentation, filtering, boiling and ageing, during which large amounts of labor is required for transporting materials from one container to another, the rice soaking process can produce a large amount of rice milk, resulting in a COD (chemical oxygen demand) up to 53000 mg / L, accordingly waste of crops and environmental pollution are caused. Therefore, the invention relates to an energy-saving and water-saving yellow wine production device integrating rice soaking, rice steaming and fermentation. The energy-saving and water-saving yellow wine production device is characterized in that 1) rice soaking is performed in a cycling spraying manner, which, compared with traditional flooding type rice soaking manners, can save water by more than 1 / 2, and meanwhile, rice milk can be completely utilized to achieve zero discharge; 2) rice soaking period is shortened to 1-2 hours, so that losses of raw material rice during rice soaking can be significantly reduced; 3) rice soaking, rice steaming and fermentation are performed in situ through one device, so that material conveying strength can be significantly reduced, energy sources, labor, facilities and rice soaking and washing water can be saved, and meanwhile production lands can also be saved.

Owner:绍兴市抱龙山酒业有限公司

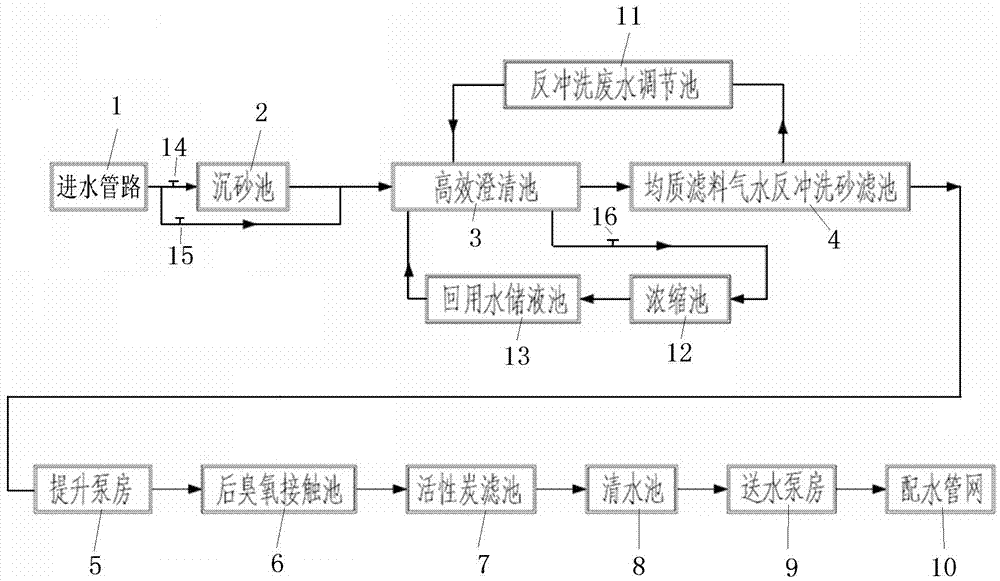

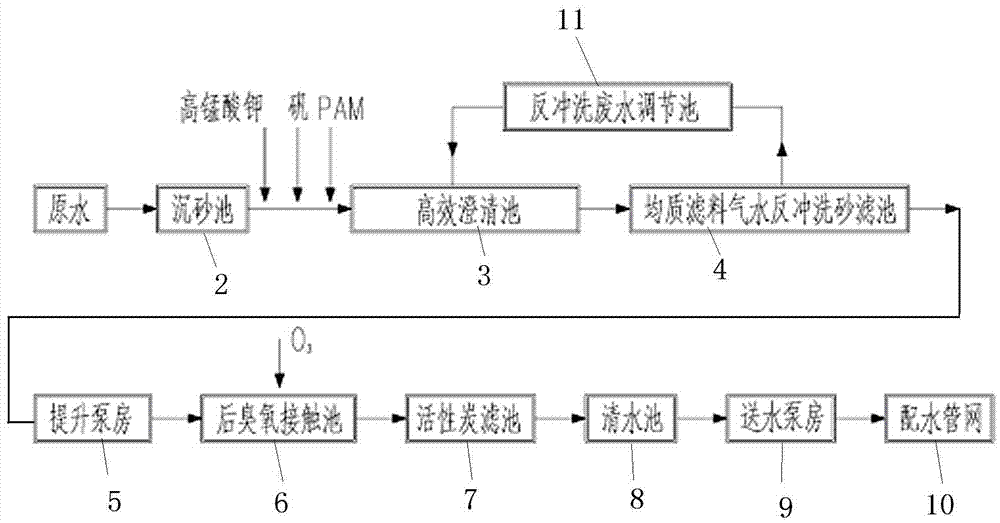

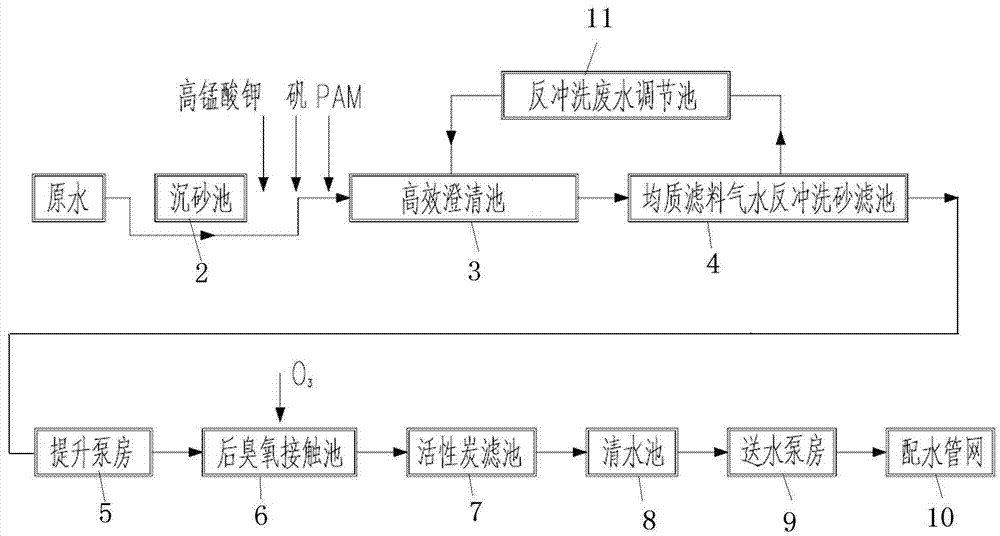

Treatment technology of water treatment device for treating raw water with higher turbidity variation

ActiveCN105439318AIncrease profitReduce production water consumptionMultistage water/sewage treatmentTurbidityWater quality

The invention discloses a water treatment device for treating raw water with higher turbidity variation and a water treatment technology of the water treatment device. Due to the characteristic of the wider turbidity variation range of the raw water, pretreatment, conventional treatment, advanced treatment and recycled water treatment processes are optimized and combined, the operation mode can be adjusted under the condition of different turbidities of the raw mater, the treatment procedure is optimized on the premise that the effluent quality is guaranteed, the production water consumption of a water factory is reduced, reusable production wastewater is recycled, and the utilization rate of the raw water is effectively increased. The combination technology has the advantages that the land can be saved, the procedure is optimized, the production water consumption is reduced and the automatic management level is improved, and has a remarkable advantage in the aspect of guarantee of the effluent quality.

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP

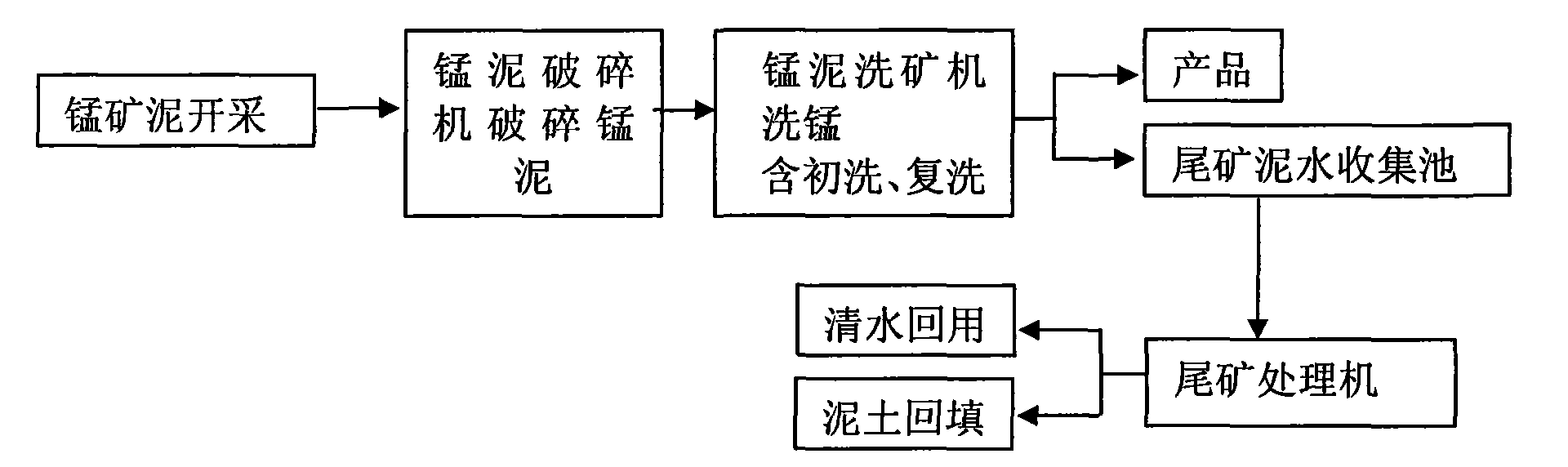

High-efficiency and energy-saving manganese washing process without arranging tailing pond or polluting environment

InactiveCN101628257AAvoid pollution effectsWon't breakGrain treatmentsWet separationManganeseWater resources

The invention discloses a high-efficiency and energy-saving manganese washing process without arranging a tailing pond and polluting the environment. The mined manganese slime is broken by a manganese slime breaking machine and then is washed by a manganese slime manganese-washing machine to obtain manganese ore, the water for washing the manganese slime enters a tailing slime water collecting tank and separated through a tailing treatment machine, the clean water is reused and the slime is back filled. The invention has the advantages that: firstly, the manganese washing is locally carried out after mining the manganese ore, therefore, the link of manganese ore slime transport is reduced and the production and transportation cost is reduced; secondly, water resources are saved and the pollution to the environment is also avoided due to the recycling of the manganese washing water; thirdly, no tailing pond is required, not only the land occupation is little, but also the original potential safety hazard of production of the tailing pond is overcome and the construction investment is reduced; and fourthly, the manganese slime breaking machine is additionally arranged, therefore, the problem that the large manganese slime cannot enter the machine before or the damage to the manganese washing machine is great is solved, and the ore washing efficiency is greatly improved by 35 percent than the original process efficiency.

Owner:陈星亮

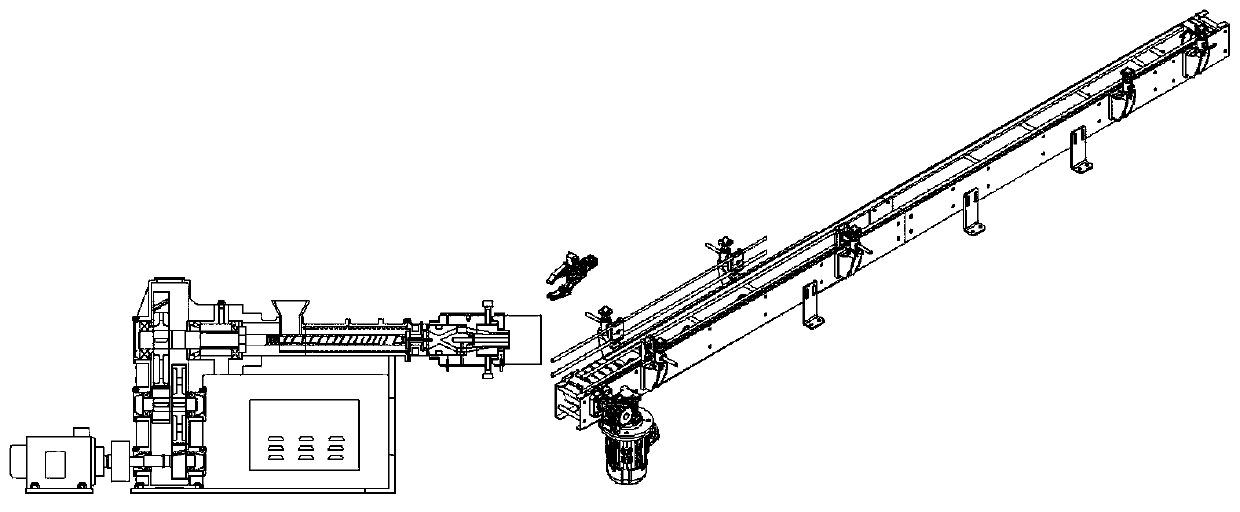

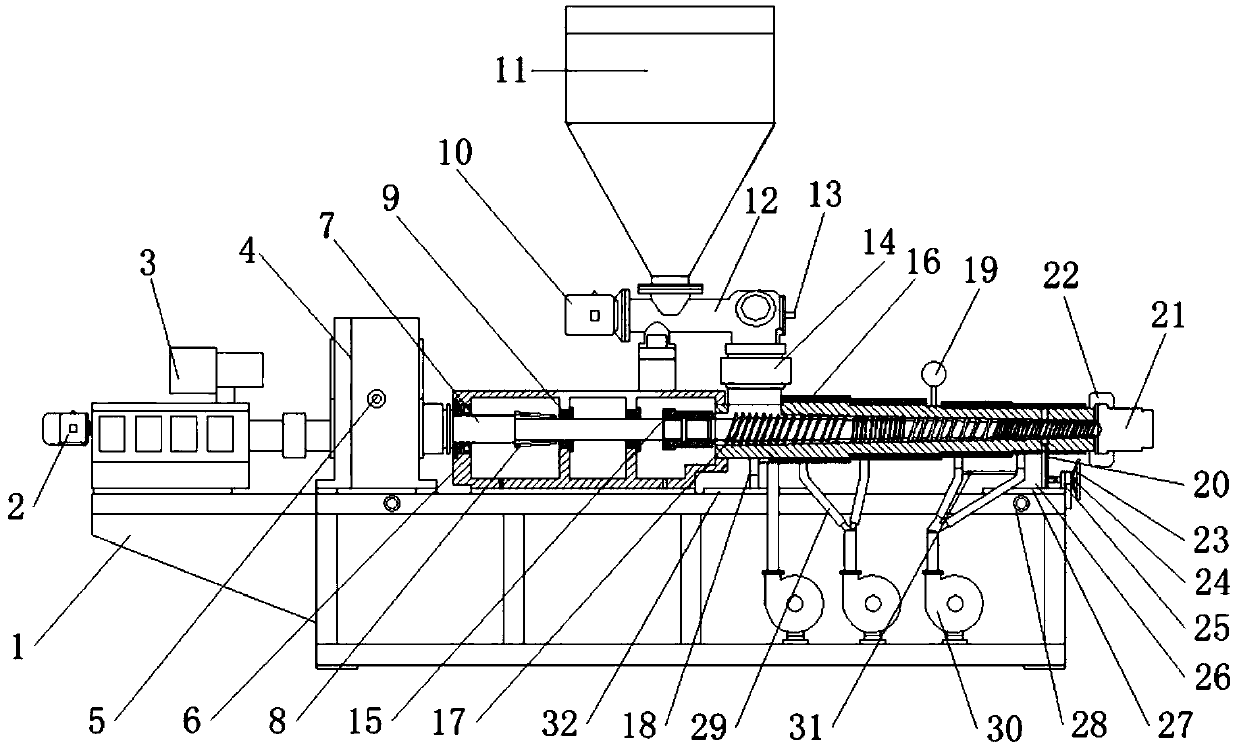

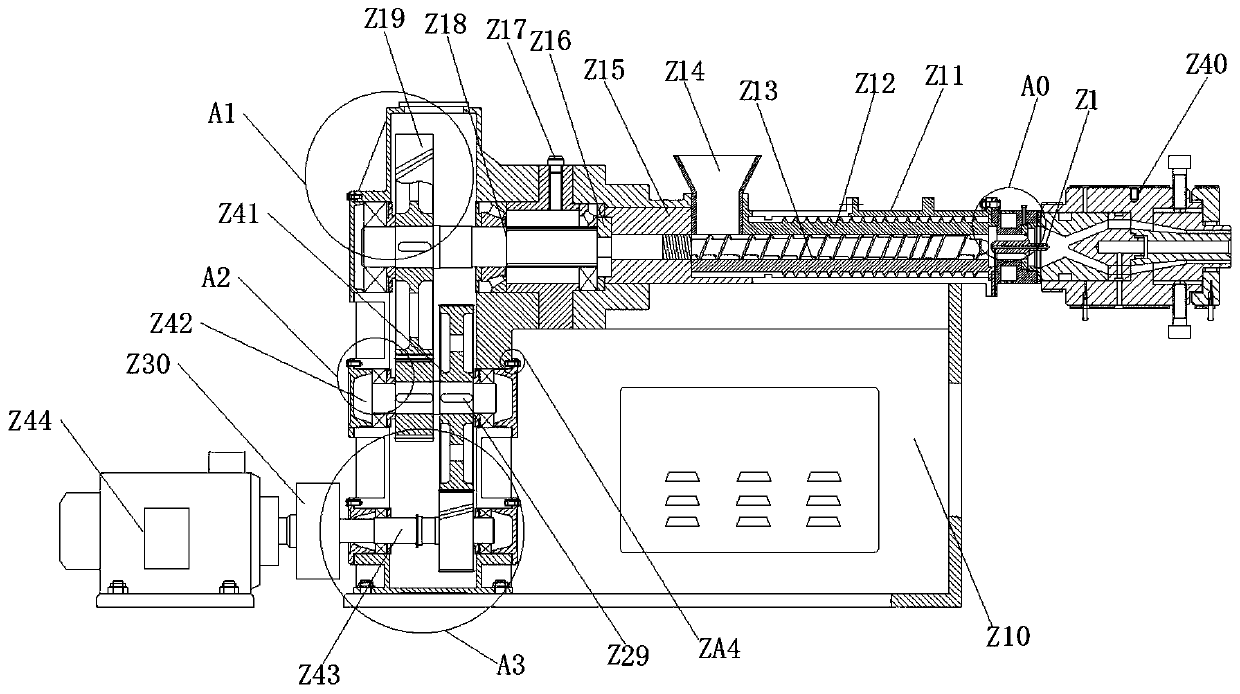

Plastic master batch, conical double screw extruding machine, and injection moulding production processing process line

The invention discloses a plastic master batch, a conical double screw extruding machine, and an injection moulding production processing process line. The gas-barrier degradable plastic master batchis composed of, by weight, 50 to 55 parts of polyhydroxyalkanoate PHA, 15 to 20 parts of polylactic acid PLA, 2 to 3 parts of feather powder, 0.2 to 0.5 part of epoxy soybean oil, 0.2 to 0.5 part of dioctyl adipate, 0.5 to 0.8 part of glycidyl methacrylate (GMA), 0.5 to 0.8 part of alpha-alkyl cyanoacrylate, 1.0 to 1.3 parts of zinc oxide, and 1.0 to 1.5 parts of graphene. The injection moulding production processing process line using the gas-barrier degradable plastic master batch comprises an injection moulding machine Z; the back part of the injection moulding machine Z is provided with injection moulding moulds including an injection moulding mould A; a plastic product is produced using the injection moulding moulds, and then is placed on a product conveyor belt D using a product clamp C; and the product clamp C is arranged on a three dimensional rotating mechanical arm.

Owner:林素治

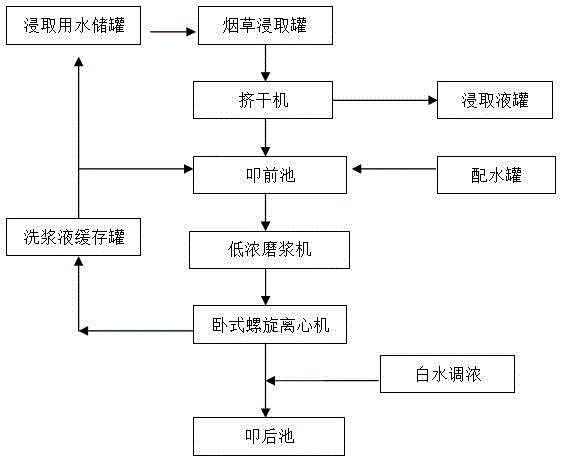

Novel papermaking method reconstituted tobacco pulp washing process

A novel papermaking method reconstituted tobacco pulp washing process includes the following steps of firstly, extracting raw materials; secondly, conducting squeeze-drying through a squeeze-drying machine, and storing the materials in an extraction liquid tank; thirdly, sending squeeze-dried materials into a before-knocking pool so that concentration can be diluted; fourthly, conducting low-concentration pulping work through a low-concentration pulping machine; fifthly, conducting solid-liquid separating through a horizontal spiral centrifugal machine; sixthly, collecting centrifuged pulp washing liquid in a buffer tank, and collecting centrifuged solid materials in an after-knocking pool. The pulp washing degree is improved, the pulp dryness degree is improved, the content of parenchyma cells, sugar and other substances in pulp is reduced, the pulp quality is good, and a paper machine can be easily accelerated. The water recycling period of a pulping system is prolonged, production water consumption is reduced, and production cost is reduced. Pulp washing liquid is comprehensively used, the raw material soluble matter extraction rate is increased, and product yield is increased. Pulp washing procedures are reasonably set, the horizontal spiral centrifugal machine is large in processing capacity, the pulp washing efficiency can be improved, device running reliability is high, and production running is stable.

Owner:HENAN CIGARETTE IND TOBACCO SLICE

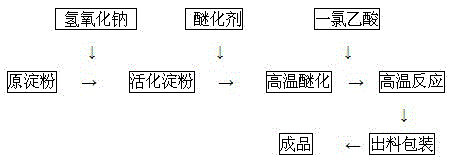

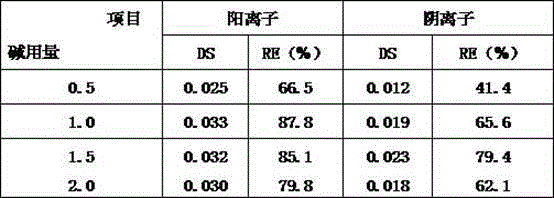

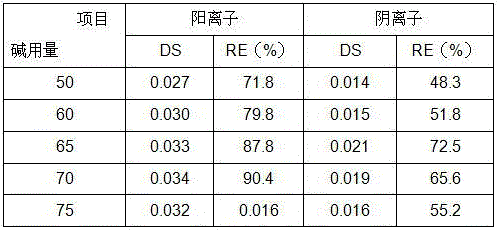

Method for preparing carboxy-type amphoteric starch in one step by semi-dry process

The invention discloses a method for preparing carboxyl-type amphoteric starch in one step by a semi-dry process, which is characterized in that: firstly adding a cationic reagent 3-chloro-2-hydroxypropyl-trimethylammonium chloride to carry out etherification reaction on the original starch, After the etherification reaction, directly add the anionizing reagent monochloroacetic acid to carry out the carboxymethylation reaction. Both anionization and cationization reactions are carried out in one kettle to prepare carboxy-type amphoteric starch in one step, and the production process is uninterrupted. The invention can effectively solve the shortcomings of wet process and dry process. Cationic and anionic groups are connected in the same starch chain, so that the product has the characteristics of cationic starch and anionic starch, and various performances are improved; the reaction time can be shortened from 8 hours to 6 hours; due to the shortened process, energy saving and consumption reduction, so that The product cost can be saved by about 12%.

Owner:抚州新天下知识产权咨询管理有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com