Industrial method for synchronously preparing stevia rebaudiana chlorogenic acid and stevioside

A technology of stevioside and chlorogenic acid, which is applied in chemical instruments and methods, separation/purification of carboxylate, preparation of carboxylate, etc. The problems of reduced isochlorogenic acid content in leaf chrysanthemum and poor product quality stability can achieve the effect of effective separation, reduction of sewage and flocculation residue discharge, and improvement of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

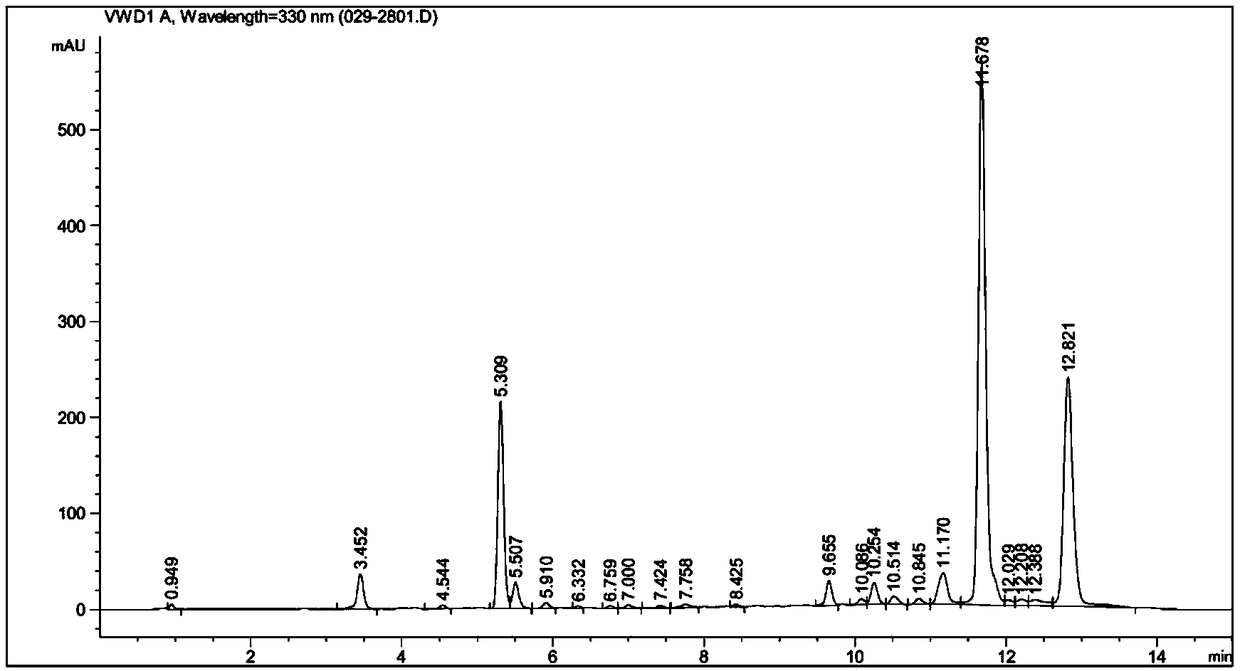

[0049] The present invention provides an industrial method for preparing stevia chlorogenic acid and the resulting product, the specific steps are as follows:

[0050] (1) Weigh 1 kg of Stevia rebaudiana powder, 85% ethanol aqueous solution as the extraction solution, the ratio of solid to liquid is 1:5 / 3.5 / 3.5, extract three times at 50°C, the first extraction time is 1.5h, 2 and 3 times The extraction time was 1 h, and the combined filtrate was used as the extract.

[0051] (2) The extract was concentrated 10 times in a water bath at 60°C and vacuum -0.08MPa to recover ethanol.

[0052] (3) Use a potentiometric titrator for on-line monitoring, use H 3 PO 4 The aqueous solution adjusts the state of the feed liquid, and the stirring is continued during the process, and the liquid addition is stopped when the electrode potential suddenly jumps.

[0053] (4) Use an equal volume of chloroform to extract the feed liquid obtained in the previous process step 3 times. After the o...

Embodiment 2

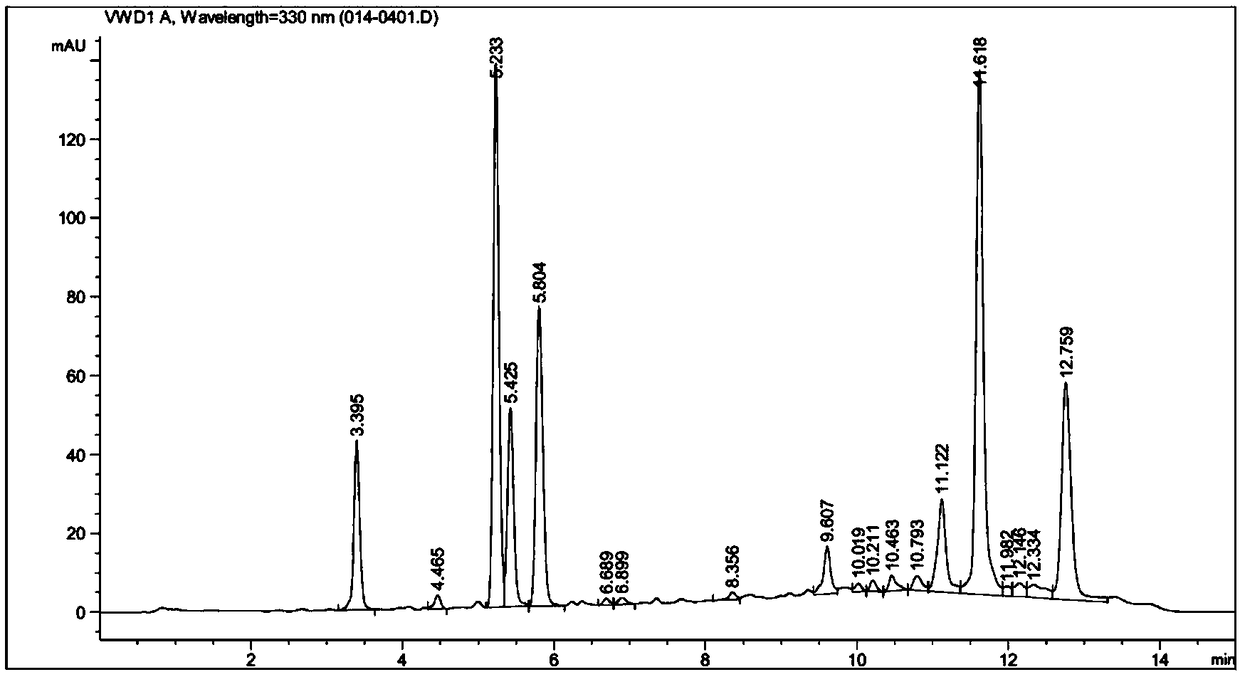

[0055] The present invention provides an industrial method for preparing stevia chlorogenic acid and the resulting product, the specific steps are as follows:

[0056] (1) Weigh 1 kg of Stevia rebaudiana powder, 95% methanol aqueous solution is the extraction solution, the ratio of solid to liquid is 1:6 / 4.5, extract twice at 50°C, the first extraction time is 1.5h, and the second extraction time Both were 1h, and the combined filtrate was used as the extract.

[0057] (2) The extract was concentrated 10 times in a water bath at 60°C and vacuum -0.08MPa to recover ethanol.

[0058] (3) Use PHS-3C pH meter for online monitoring, use H 2 SO 4 The aqueous solution adjusts the state of the feed liquid, and the process is continuously stirred until the electrode potential is 180mV to stop adding liquid.

[0059] (4) Using an equal volume of ethyl acetate to extract the feed liquid obtained in the previous process step 3 times, after the organic phase was concentrated and the res...

Embodiment 3

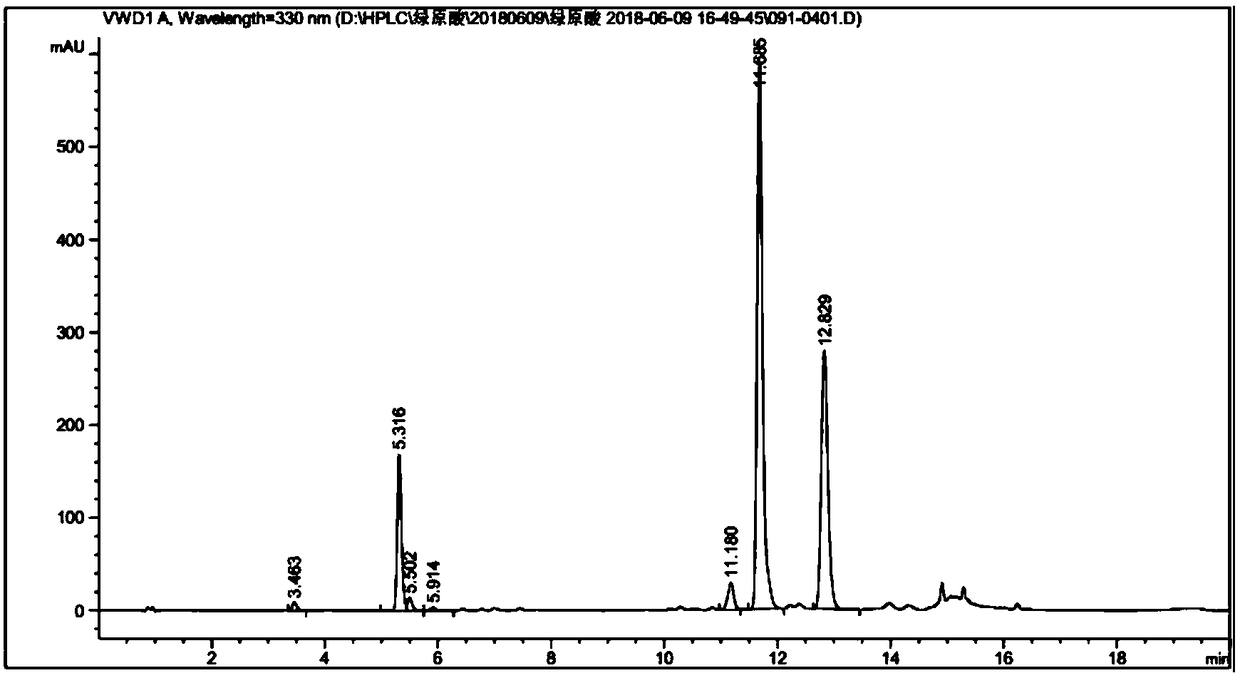

[0061] The present invention provides an industrial method for preparing stevia chlorogenic acid and the resulting product, the specific steps are as follows:

[0062] (1) Weigh 1 kg of Stevia rebaudiana powder, 75% propanol aqueous solution is the extraction solution, the ratio of solid to liquid is 1:6 / 4.5, extract twice at 50°C, the first extraction time is 1.5h, and the second extraction The time is 1h, and the combined filtrate is used as the extract.

[0063] (2) The extract was concentrated 10 times in a water bath at 60°C and vacuum -0.08MPa to recover ethanol.

[0064] (3) Use a PHS-3C pH meter for online monitoring, use formic acid aqueous solution, and keep stirring during the process, and stop adding liquid when the pH is 3.0.

[0065] (4) Use an equal volume of ether to extract the feed liquid obtained in the previous process step 3 times. After the organic phase is concentrated and the resin is purified, 72.8g of stevia chlorogenic acid product is obtained. The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com