Industrial utilization method for stevia, stevioside and chlorogenic acid

A technology of steviol glycosides and stevia, applied in chemical instruments and methods, separation/purification, and application of carboxylic acid esters, can solve problems such as inability to obtain stevia chlorogenic acid, affect the quality of glycoside products, and fail to meet market requirements , to achieve effective separation, improve purity and quality, improve efficiency and life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

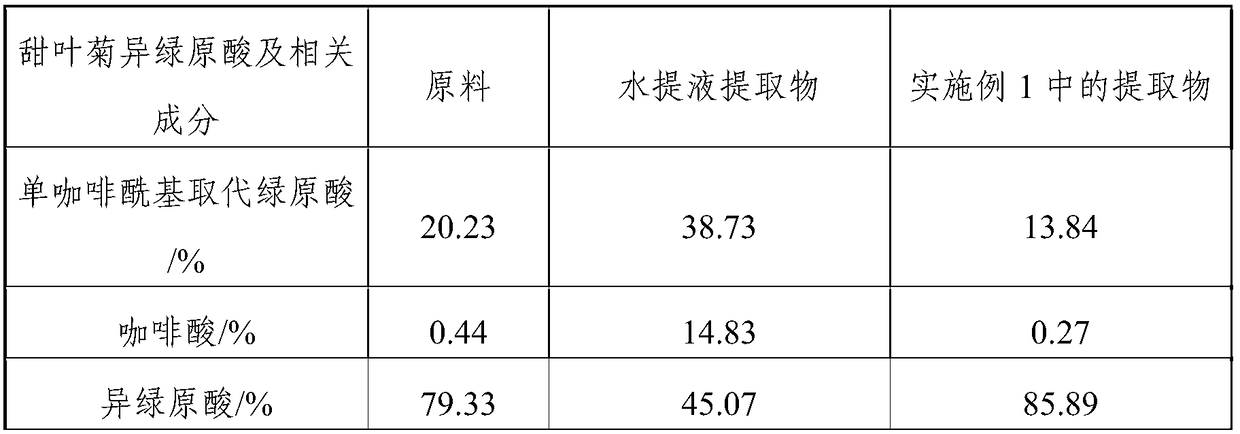

Embodiment 1

[0057] This embodiment relates to a method for industrialized utilization of stevia, comprising the following steps:

[0058] (1) Take 1 kg of stevia powder by weighing, use 85% ethanol aqueous solution as extracting liquid, repeat extraction 3 times to the powder of described stevia under the condition of 50 ℃, the solid-liquid ratio in 3 extraction processes is respectively 1 : 5 / 3.5 / 3.5, the 1st extraction time is 1.5h, the 2nd and 3rd extraction time is 1h, and the combined filtrate is used as extracting solution;

[0059] (2) Concentrate the extract to 1 / 10 of the original volume in a water bath at 60°C and vacuum-0.08MPa, add an equal volume of n-hexane to the concentrate for liquid-liquid extraction for 3 times, take the water layer to obtain Extraction solution with low polarity impurities;

[0060] (3) Adjust the pH of the extract to remove low-polar impurities to 10.0, and adjust the solid content to 10%, then adsorb it through 1.5L of T28 resin, and adjust the flow...

Embodiment 2

[0063] This embodiment relates to a method for industrialized utilization of stevia, comprising the following steps:

[0064] (1) Take by weighing 1 kg of stevia powder, use 95% methanol aqueous solution as extracting liquid, repeat extraction 2 times to the powder of described stevia under the condition of 50 ℃, the solid-liquid ratio in 2 extraction processes is respectively 1 : 6 / 4.5, the 1st extraction time is 1.5h, the extraction time of the 2nd time is 1h, and the combined filtrate is used as extractant;

[0065] (2) Concentrate the extract to 1 / 10 of the original volume in a water bath at 60°C and a vacuum of -0.08MPa, add an equal volume of diethyl ether to the concentrate for liquid-liquid extraction for 3 times, take the water layer, and obtain the low Extraction of polar impurities;

[0066] (3) Adjust the pH of the extract to remove low-polarity impurities to 9.5, and adjust the solid content to 8%, which is adsorbed by 1.5L of 201-H resin, and the flow rate of th...

Embodiment 3

[0069] This embodiment relates to a method for industrialized utilization of stevia, comprising the following steps:

[0070] (1) Take by weighing 1 kg of stevia powder, use 75% propanol aqueous solution as extracting liquid, repeat extraction 2 times to the powder of described stevia under the condition of 50 ℃, the solid-liquid ratio in 2 extraction processes is respectively 1:6 / 4.5, the extraction time for the first time is 1.5h, the extraction time for the second time is 1h, and the combined filtrate is used as the extraction solution;

[0071] (2) Concentrate the extract to 1 / 10 of the original volume in a water bath at 60° C. and a vacuum of -0.08 MPa, add an equal volume of cyclohexane to the concentrate for liquid-liquid extraction for 3 times, and take the water layer to obtain Extraction solution to remove low-polarity impurities;

[0072] (3) Adjust the pH of the extract to remove low-polarity impurities to 9.0, and adjust the solid content to 6%. It is adsorbed by...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com