Novel papermaking method reconstituted tobacco pulp washing process

A technology of reconstituted tobacco leaves and papermaking method, which is applied in the field of pulp washing process of reconstituted tobacco leaves by new papermaking method, which can solve the problems of high temperature and high humidity in the working environment, small use range of preservatives, high concentration of fine fibers, etc., so as to improve the cleaning degree of pulp, High reliability of equipment operation and good slurry quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

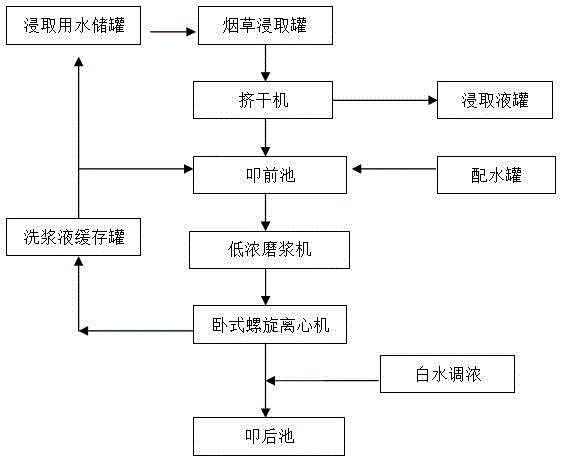

[0022] like figure 1 Shown, a kind of novel papermaking method reconstituted tobacco leaf pulp washing process of the present invention comprises the following steps:

[0023] (1) The raw material is leached in the tobacco leaching tank;

[0024] (2) The leached raw materials are transported to the squeeze dryer and squeezed dry, and the leaching liquid is transported to the leaching liquid tank for storage;

[0025] (3) The squeezed material is sent to the pre-knock tank to dilute the concentration;

[0026] (4) Use a low consistency refiner for low consistency beating;

[0027] (5) The pulp after beating is separated into solid and liquid by a horizontal screw centrifuge;

[0028] (6) The centrifuged washing liquid is collected into the buffer tank; a part of the washing liquid in the buffer tank is measured and used to adjust the material concentration in the pre-knock tank, and a part of the washing liquid in the buffer tank is measured and poured into the leaching wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com