Rhodotorula, culture method thereof and application of rhodotorula in production of biolipid

A cultivation method and bio-oil technology, applied in the field of red yeast, can solve problems such as unfavorable industrial application of red yeast, increased product impurity content, sensory and quality decline, etc., to reduce post-processing difficulty, improve bio-oil quality, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The inventor isolated and screened the initial strain from a potato stem. Pick a single colony growing on the yeast extract-peptone-glucose-agar (YPD) solid medium, dilute it with normal saline and spread it on fresh YPD medium. After a single colony grows, re-dilute and spread it according to the above method . After 10 repetitions, the colonies were consistent with the cell shape and stable in character. The composition of the yeast extract-peptone-glucose-agar (YPD) solid medium is: 1% yeast extract, 2% peptone, 2% glucose, and 2% agar powder.

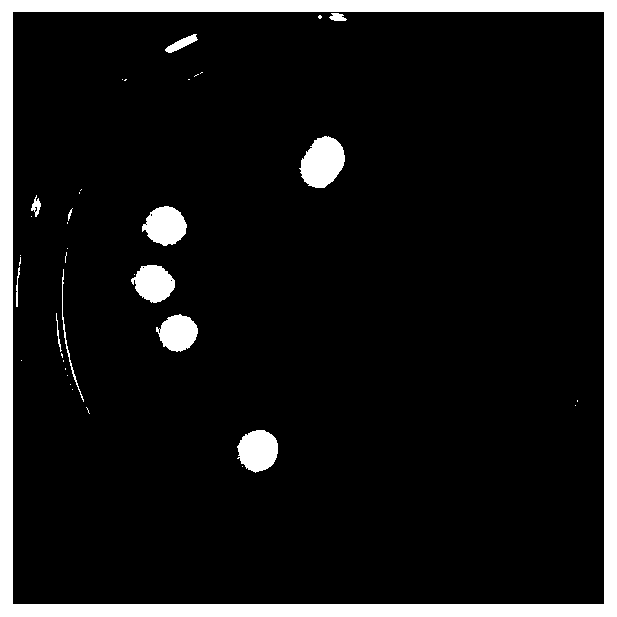

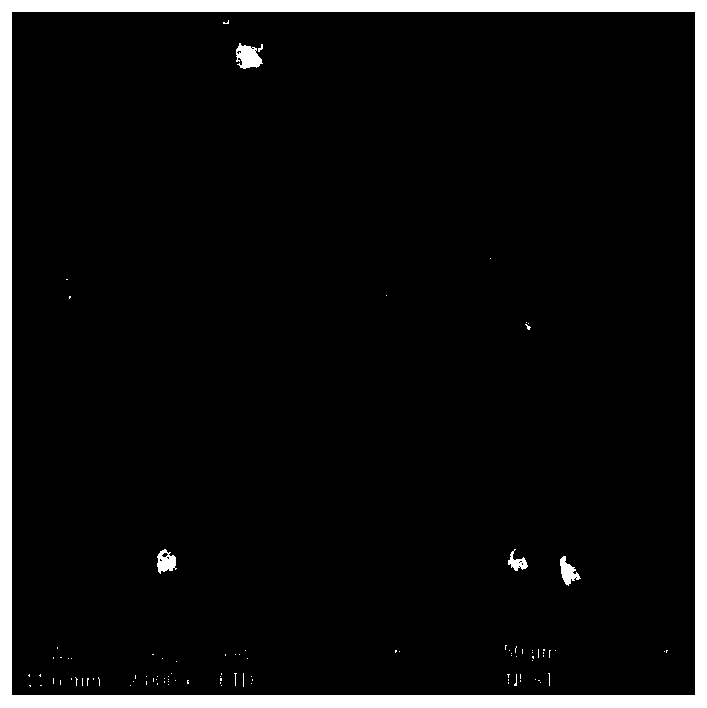

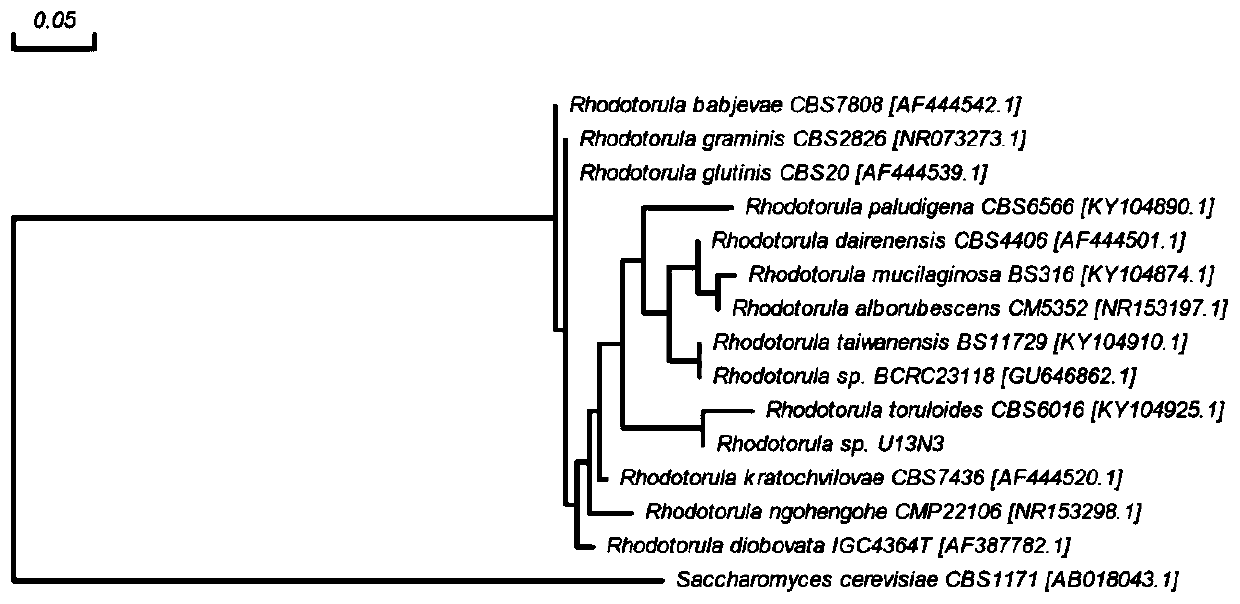

[0033] After the strain was cultured on YPD solid medium at 30°C for 3 days, the colony was nearly round, with a smooth and shiny surface, slightly raised in the middle, neat edges, and off-white ( figure 1 ). After the bacterium colony is dispersed, it is observed under a scanning electron microscope, the thalline is oval, and multiple thallines are connected into long chains ( figure 2 ). Suspend the colonies in norma...

Embodiment 2

[0036] A single colony of Rhodotorula U13N3 grown on YPD solid medium was picked and inoculated into 20 mL of a 100 mL shake flask containing seed medium, cultured at 25°C for 48 h, and the shake flask rotated at 100 rpm to obtain a seed culture solution. The composition of the seed medium is: glucose 30g / L, K 2 HPO 4 2g / L, yeast powder 1.5g / L, MgSO 4 ·7H 2O 1.5g / L, (NH 4 ) 2 SO 4 1.2g / L, pH 4.5.

[0037] Take 20mL of seed solution and inoculate into a 500mL shake flask containing 80mL of fermentation medium, the inoculation amount is 10%, and culture at 100rpm and 25°C for 6 days to obtain a fermentation medium. The composition of the fermentation medium is: glycerol 30g / L, K 2 HPO 4 2g / L, yeast powder 1.5g / L, MgSO 4 ·7H 2 O 1.5g / L, (NH 4 ) 2 SO 4 1.2g / L, pH 6.5.

[0038] The obtained fermented liquid is centrifuged to obtain the red yeast cell. Then add 6 mol / L hydrochloric acid until the final concentration of hydrochloric acid is 4 mol / L, then treat in a wat...

Embodiment 3

[0042] According to the method of Example 2, Rhodotorula U13N3 was inoculated into the seed medium, cultured at 35° C. for 24 hours, and the rotation speed of the shake flask was 300 rpm, to obtain a seed culture solution. The composition of the seed medium is: glycerol 30g / L, K 2 HPO 4 2g / L, yeast powder 1.5g / L, MgSO 4 ·7H 2 O 1.5g / L, (NH 4 ) 2 SO 4 1.2g / L, pH 5.9.

[0043] The obtained seed culture solution was inoculated into the fermentation medium with an inoculation amount of 5%, and cultured at 300 rpm and 37° C. for 9 days to obtain a fermentation medium. The composition of the fermentation medium is: glycerol 60g / L, K 2 HPO 4 2g / L, yeast powder 1.5g / L, MgSO 4 ·7H 2 O 1.5g / L, (NH 4 ) 2 SO 4 1.2g / L, pH 5.6. The obtained fermentation culture liquid is subjected to solid-liquid separation to obtain Rhodotorula thallus.

[0044] Wash the Rhodotorula thallus once with physiological saline, and extract oil according to the method described in Example 2, and fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com