Rotating disc type micro-grid assembly for backwash-free dynamic membrane

A backwash and turntable technology, applied in sustainable biological treatment, water/sludge/sewage treatment, biological water/sewage treatment, etc., can solve the problem of affecting water production rate, high equipment investment, and decreased film adhesion To achieve the effect of reducing production water consumption, solving uneven generation, and maintaining filtration flux

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

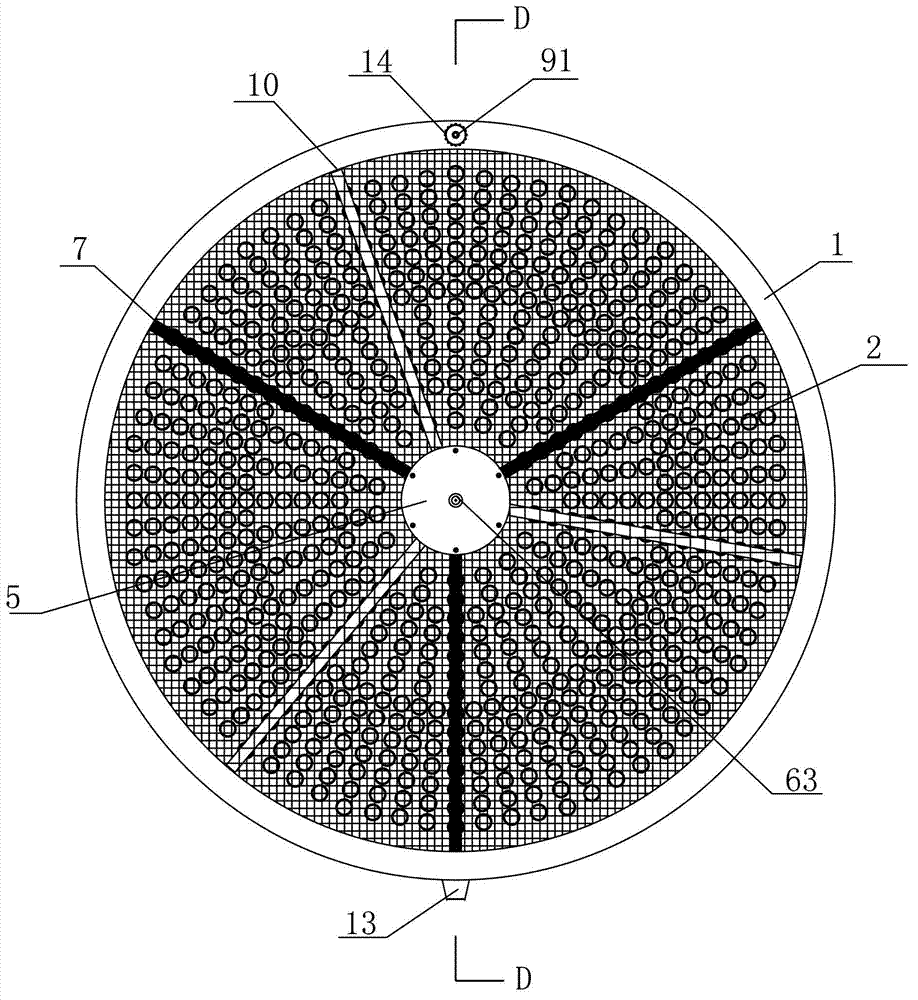

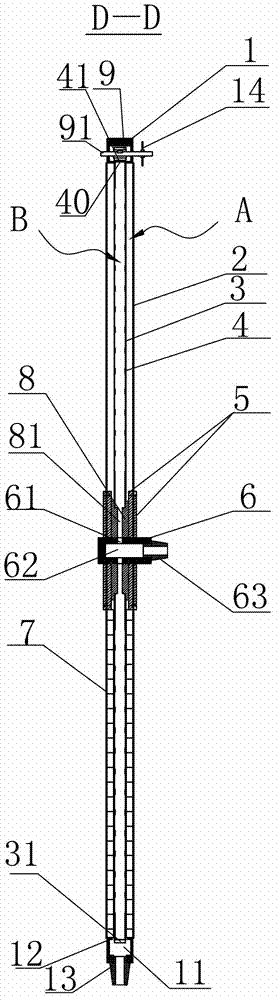

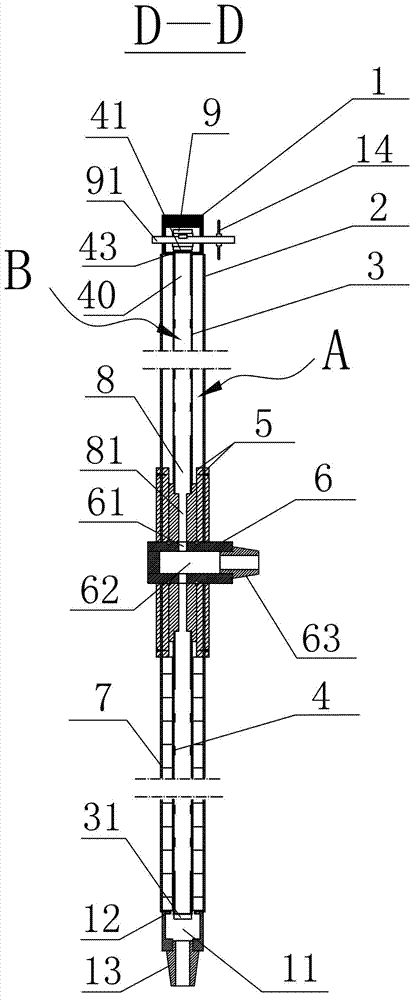

[0021] Figure 1 to Figure 4It shows a rotating disk type non-backwashing dynamic membrane micro-grid assembly, which includes a disc-shaped interior formed by a rigid impermeable circular frame 1 and a micro-network matrix fixed and packaged on both ends of the circular frame as a micro-network space. The filter box of the cavity is characterized in that the above-mentioned micro-network matrix is the outer micro-network 2, the above-mentioned filter box is the outer filter box A, and the center of the circle of the outer filter box A is provided with an internal water collector that is perpendicular to its disk surface and passes through the outer filter box body. The central water outlet pipe 6 of chamber 62, one end of water outlet pipe 6 is sealed, and the other end stretches out outer filter case A, and water outlet nozzle 63 is installed at the end. Set the water outlet turntable 8 which is slidingly matched with it on the center outlet pipe, respectively set the clam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com