Preparation method of modified material for PVC

A modified material and modified technology, applied in the field of plastic processing aids, can solve the problems of high cost and large production gap, and achieve the effects of improving reinforcement performance, strong positive electricity, and improving impact resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

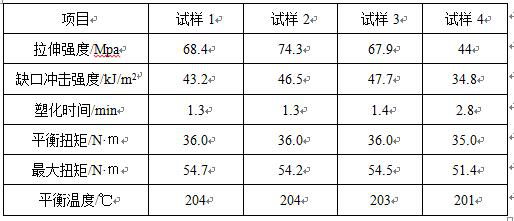

Examples

Embodiment 1

[0028] The preparation method of modified material for PVC, concrete steps are as follows:

[0029] S1: on nano-SiO 2 Into the surface treatment

[0030] nano-SiO 2 Powder added to silane coupling agent (butadienyltriethoxysilane, 1.0% nano-SiO 2 ) in the dilute alcohol aqueous solution, after fully mixing and stirring for 30 minutes, vacuum drying to obtain modified nano-SiO 2 ;

[0031] S2: Configure seed emulsion

[0032] A certain amount of nano-SiO 2 dispersed in deionized water (nano-SiO 2 The mass ratio to deionized water is 3:100), after pre-dispersion by ultrasonic dispersion and mechanical stirring for 35min, then add emulsifier (sodium dodecylbenzenesulfonate, 5% nano-SiO 2 ) After dispersing for 15 minutes, adjust the pH value to 9-10 with 5% sodium hydroxide solution, and then disperse for 30-40 minutes with ultrasonic high-speed stirring to obtain seed latex;

[0033] S3: Preparation of core-shell modification additives

[0034] Add the seed latex obtain...

Embodiment 2

[0036] The preparation method of modified material for PVC, concrete steps are as follows:

[0037] S1: on nano-SiO 2 Into the surface treatment

[0038] nano-SiO 2 Powder added to silane coupling agent (butadienyltriethoxysilane, 0.5% nano-SiO 2 ) in the dilute alcohol aqueous solution, after fully mixing and stirring for 30 minutes, vacuum drying to obtain modified nano-SiO 2 ;

[0039] S2: Configure seed emulsion

[0040] A certain amount of nano-SiO 2 dispersed in deionized water (nano-SiO 2 The mass ratio to deionized water is 6:100), after pre-dispersion by ultrasonic dispersion and mechanical stirring for 35min, then add emulsifier (sodium dodecylbenzenesulfonate, 5% nano-SiO 2 ) After dispersing for 15 minutes, adjust the pH value to 9-10 with 5% sodium hydroxide solution, and then disperse for 30-40 minutes with ultrasonic high-speed stirring to obtain seed latex;

[0041] S3: Preparation of core-shell modification additives

[0042] Add the seed latex obtain...

Embodiment 3

[0044]The preparation method of modified material for PVC, concrete steps are as follows:

[0045] S1: on nano-SiO 2 Into the surface treatment

[0046] nano-SiO 2 Powder added to silane coupling agent (butadienyltriethoxysilane, 1% nano-SiO 2 ) in the dilute alcohol aqueous solution, after fully mixing and stirring for 30 minutes, vacuum drying to obtain modified nano-SiO 2 ;

[0047] S2: Configure seed emulsion

[0048] A certain amount of nano-SiO 2 dispersed in deionized water (nano-SiO 2 The mass ratio to deionized water is 6:100), after pre-dispersion by ultrasonic dispersion and mechanical stirring for 35min, then add emulsifier (sodium dodecylbenzenesulfonate, 5% nano-SiO 2 ) After dispersing for 15 minutes, adjust the pH value to 9-10 with 5% sodium hydroxide solution, and then disperse for 30-40 minutes with ultrasonic high-speed stirring to obtain seed latex;

[0049] S3: Preparation of core-shell modification additives

[0050] Add the seed latex obtained ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com