A kind of positively charged nanometer yttrium oxide and preparation method thereof

A nano-yttrium oxide, positively charged technology, applied in chemical instruments and methods, nanotechnology, rare earth metal oxides/hydroxides, etc., can solve the limitations of the development and application of charged ceramic films, weak surface electrical properties, base Problems such as weak membrane binding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) Add ethanol and deionized water to a stirred reactor at a mass ratio of 1:10, then add yttrium acetate, control the molar concentration of yttrium ions in the solution to 0.2mol / L, and heat it to 70℃. Under stirring conditions, urea with a molar concentration of 0.8 mol / L was slowly added to react for 4 hours to obtain a precursor sol containing yttrium. Then it was transferred to a high-speed centrifuge at 12000r / min for centrifugal sedimentation for 0.5h, the upper solvent was removed, the lower sediment was taken out, washed, and dried in an oven at 120°C for 4h to obtain the yttrium-containing precursor.

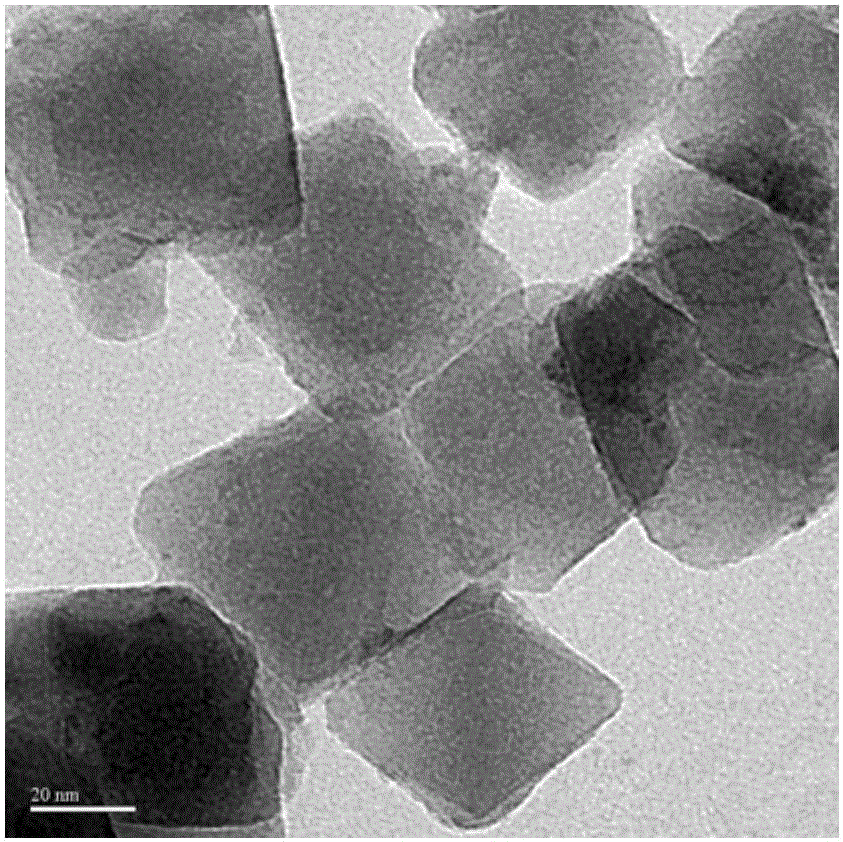

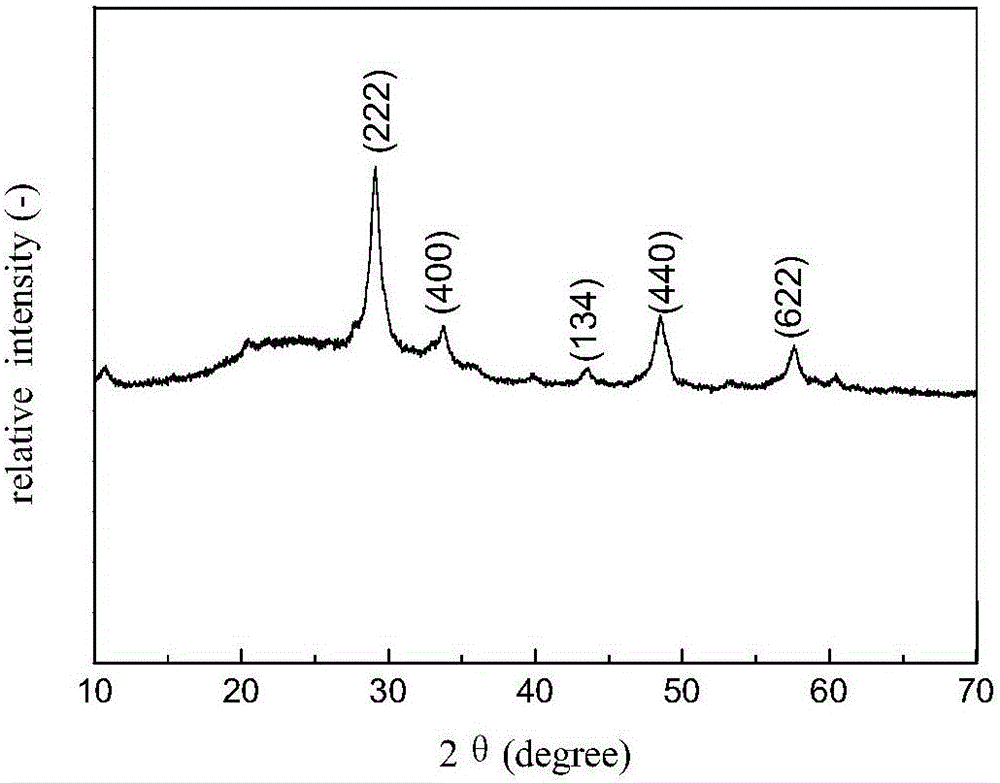

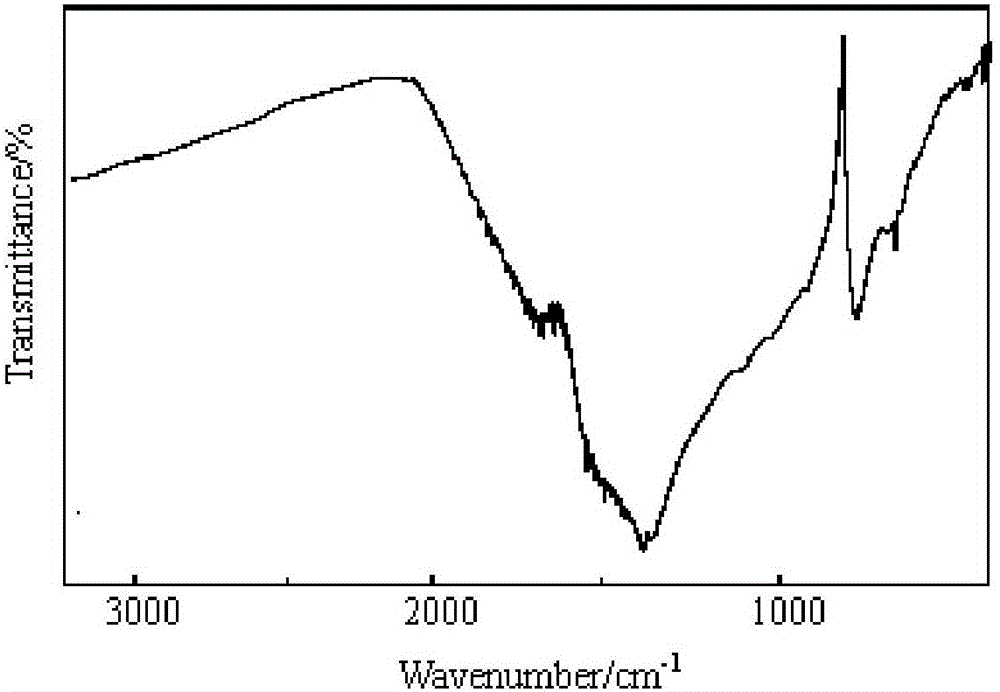

[0027] (2) Place the yttrium-containing precursor obtained in step (1) in a tube furnace, under the protection of a nitrogen atmosphere, gradually increase the temperature to 600°C at a heating rate of 2°C / min, and heat it for 1.5h to heat Yttrium precursor is completely converted to inorganic Y 2 O 3 Crystal structure, positively charged nano Y is prepared after...

Embodiment 2

[0031] (1) Add n-propanol and deionized water to a stirred reactor at a mass ratio of 1:5, then add yttrium acetate, control the molar concentration of yttrium ions in the solution to 0.1 mol / L, and heat to 85°C. Under the condition of magnetic stirring, urea with a molar concentration of 0.5 mol / L was slowly added to react for 3 hours to obtain a precursor sol containing yttrium. Then it was transferred to a high-speed centrifuge at 12000r / min for centrifugal sedimentation for 0.5h, the upper solvent was removed, the lower sediment was taken out, washed, and dried in an oven at 100°C for 6h to obtain the yttrium-containing precursor.

[0032] (2) Place the yttrium-containing precursor obtained in step (1) in a tube furnace, under the protection of a nitrogen atmosphere, gradually increase the temperature to 650°C at a heating rate of 1°C / min, heat it for 1.5h, and perform high temperature heat treatment. Positively charged nano Y 2 O 3 .

[0033] Nano Y prepared in Example 2 2 O ...

Embodiment 3

[0035] (1) Add isopropanol and deionized water into a stirred reactor at a mass ratio of 1:5, then add yttrium acetate, control the molar concentration of yttrium ions in the solution to 2mol / L, and heat to 75°C. Under stirring conditions, urea with a molar concentration of 4 mol / L was slowly added to react for 2 hours to obtain a precursor sol containing yttrium. Then it was transferred to a high-speed centrifuge at 12000r / min for centrifugal sedimentation for 0.5h, the upper solvent was removed, the lower sediment was taken out, washed, and dried in an oven at 100°C for 6h to obtain the yttrium-containing precursor.

[0036] (2) Place the yttrium-containing precursor obtained in step (1) in a tube furnace, under the protection of a nitrogen atmosphere, gradually increase the temperature to 550°C at a heating rate of 3°C / min, heat it for 2h, and perform high-temperature heat treatment. Positively charged nano Y 2 O 3 .

[0037] Nano Y prepared in Example 3 2 O 3 It has a body-cen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com