A light modified filter material and its preparation method and application

A modified and lightweight technology, applied in the field of water treatment, can solve the problems of low surface adsorption capacity, small specific surface area, low porosity, etc., and achieve the effect of improving isoelectric point and service life, large specific surface area, and enhanced strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

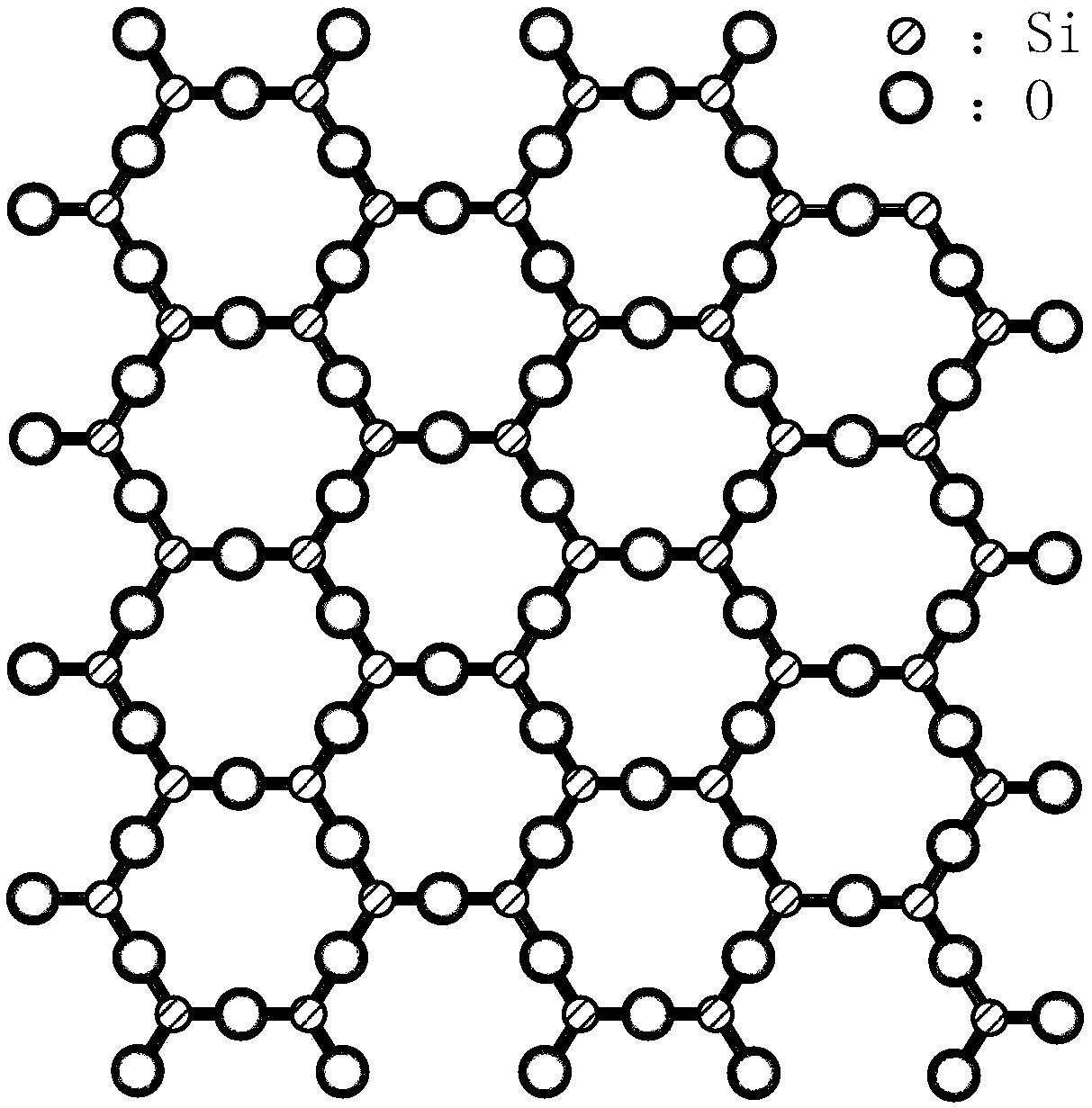

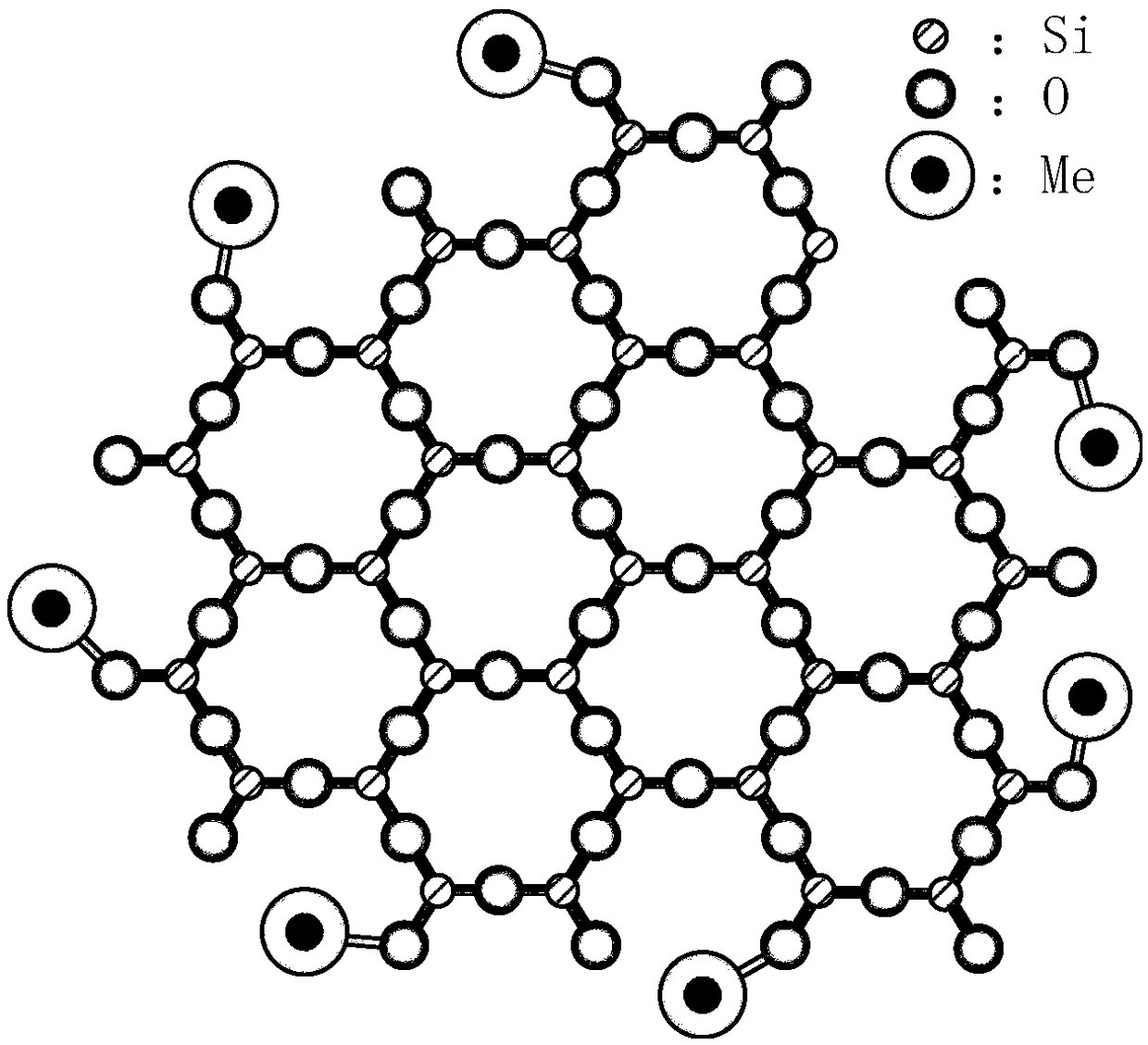

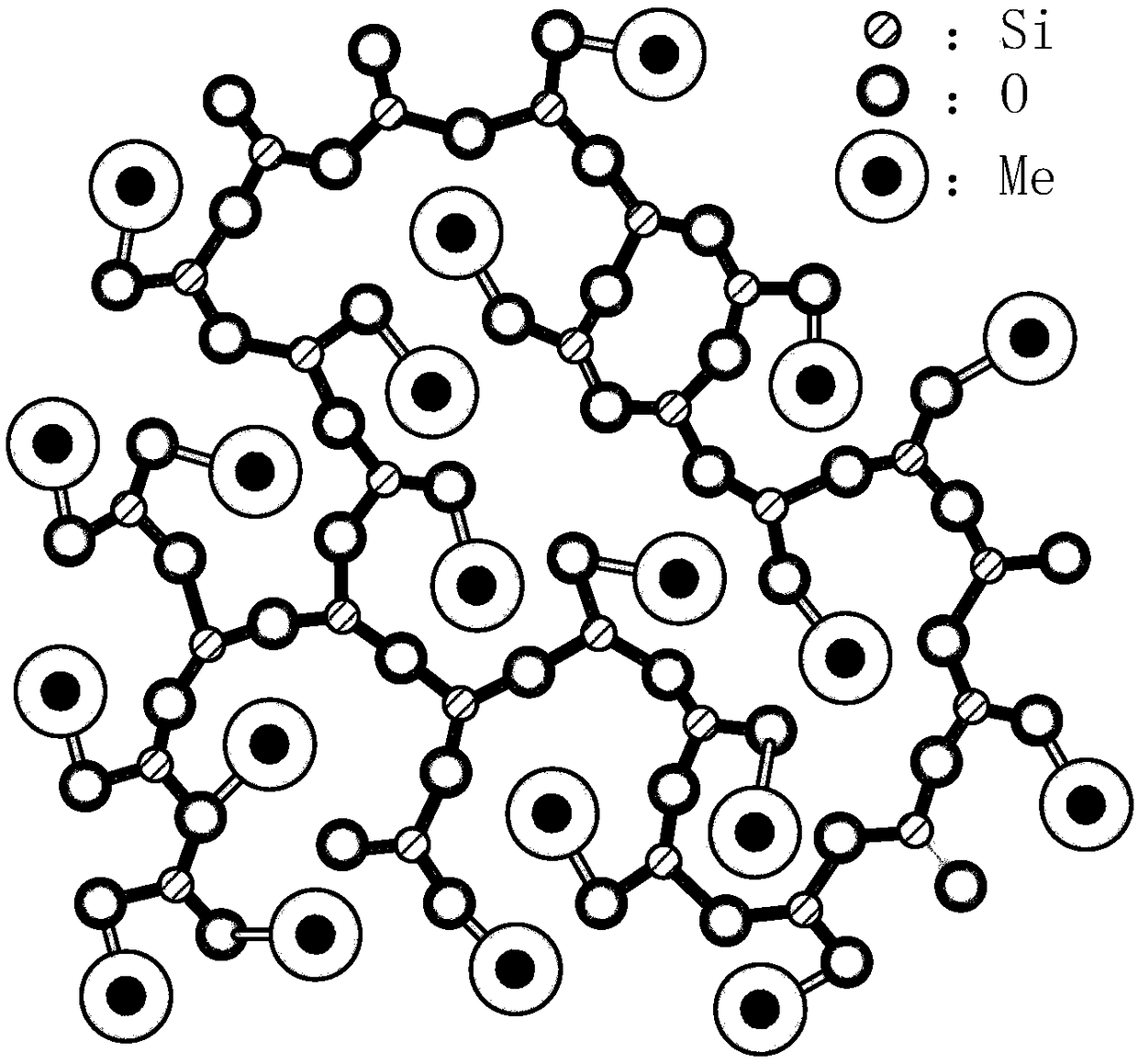

Image

Examples

preparation example Construction

[0053] The preparation method of described lightweight modified filter material, comprises the following steps:

[0054] The waste glass is crushed, crushed and ground, then metal oxide modifier and foaming agent are added, heated and melted, foamed, solidified, cooled, crushed after cooling, and the particle size is screened to obtain the light modified filter material .

[0055] The preparation method of lightweight filter material provided by this application uses the crushed, washed and dried waste glass powder as the main raw material, adding a specific number of metal oxide modifiers and foaming agents, and finely pulverizing and uniformly After mixing, it is a lightweight filter material made by high temperature melting, foaming and annealing. After further processing such as crushing and screening, a new type of light weight, high isoelectric point, large specific surface area, and porosity new type of whole body modified glass filter material for water treatment is o...

Embodiment 1

[0063] The waste glass is crushed to obtain 3mm glass fragments, and the glass fragments are crushed into fine glass powder with a particle size of 100 μm;

[0064] Add 1 part of foaming agent (carbon black) and 5 parts of metal oxide modifier (titanium oxide) to 75 parts by weight of fine glass powder and mix to obtain a mixed raw material;

[0065] After the mixed raw materials are melted and foamed, they are sequentially cooled and pulverized again to obtain foam glass; wherein, during the process of melting and foaming, the melting and foaming furnace is raised to 600°C at a rate of 10°C / min, and foamed for 3 hours. Then it is solidified and cooled, crushed after cooling, and the particle size is screened to obtain the light modified filter material.

Embodiment 2

[0067] Crushing waste glass to obtain 4mm glass fragments, and crushing the glass fragments to fine glass powder with a particle size of 200 μm;

[0068] After adding 10 parts of foaming agent (calcium carbonate) and 20 parts of metal oxide modifier (iron oxide) to 100 parts by weight of fine glass powder, mix them evenly to obtain mixed raw materials;

[0069] After the mixed raw materials are melted and foamed, they are cooled and crushed again to obtain foam glass; wherein, during the process of melting and foaming, the melting and foaming furnace is raised to 1100°C at a rate of 10°C / min, and foamed for 2 hours. Then it is solidified and cooled, crushed after cooling, and the particle size is screened to obtain the light modified filter material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com