A preparation method of titanium-doped birnessite for efficient treatment of antimony wastewater

A technology of titanium birnessite and birnessite, which is applied in the application field of titanium-doped birnessite as an adsorbent to remove antimony in wastewater, can solve the problem of large amount of iron-manganese oxide sludge, low manganese oxide adsorption capacity, and adsorption efficiency. Low-level problems, to achieve the effect of solving the pH limit of wastewater, enhancing the ability to remove antimony, and lowering the preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

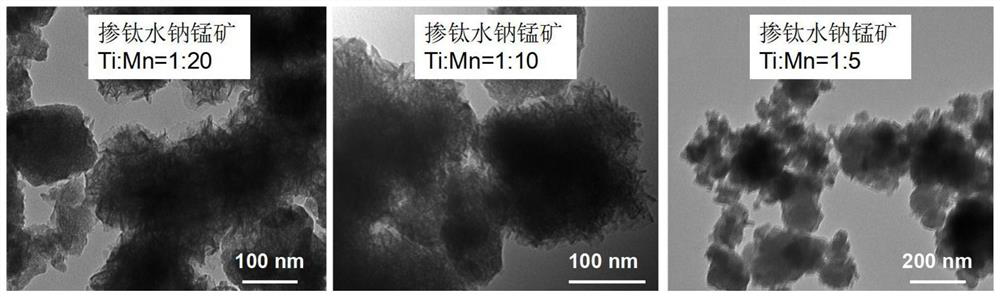

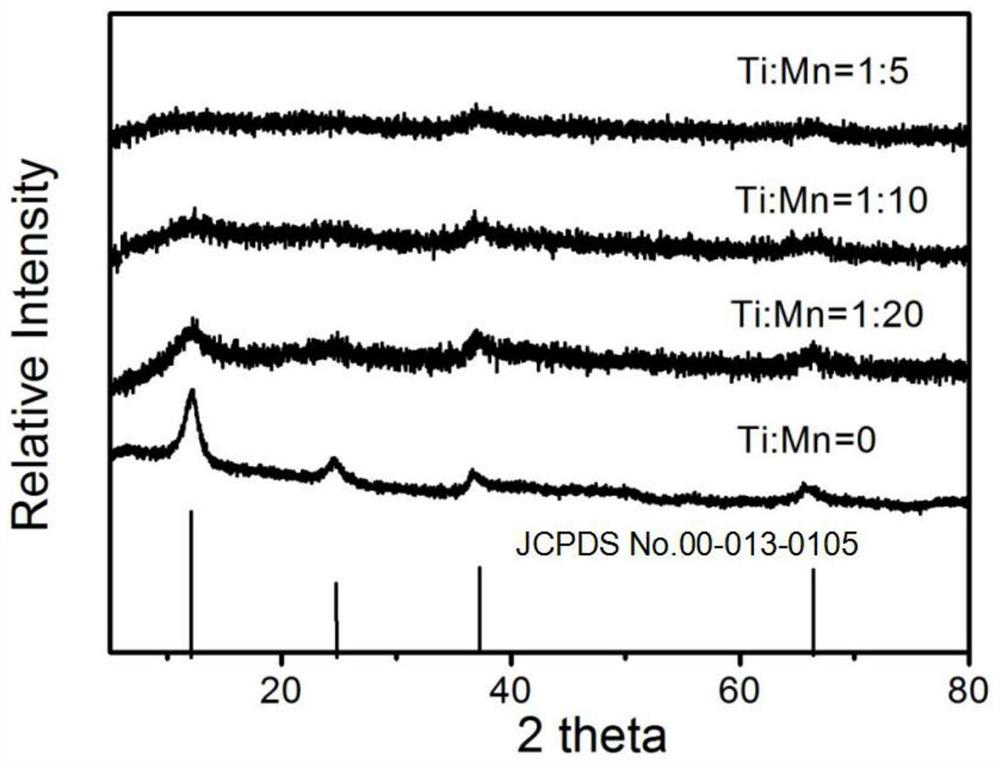

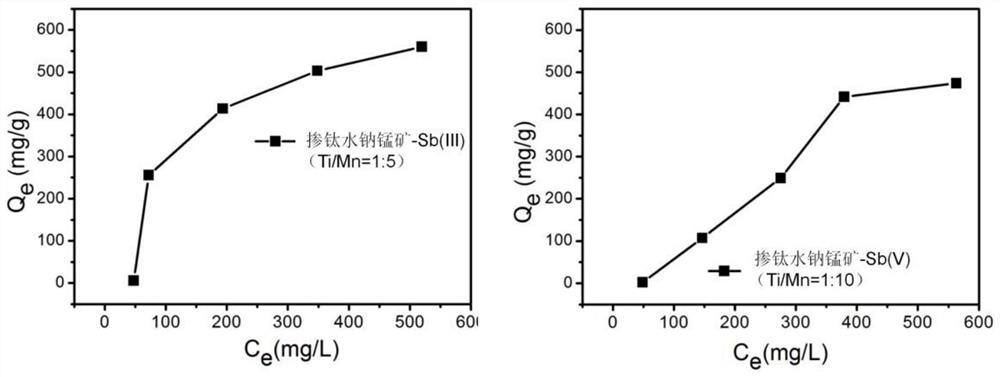

[0022] Example 1 A high-efficiency titanium-doped birnessite material for antimony removal is synthesized from potassium permanganate and titanium sulfate at a mass ratio of 13.2:1 (ie molar ratio Ti / Mn=1:20).

[0023] A method for preparing titanium-doped birnessite that can efficiently remove trivalent antimony as described above comprises the following steps:

[0024] (1) Potassium permanganate is 1:9.5-10.5 (g / ml) is placed in the Erlenmeyer flask that adds deionized water according to material-liquid ratio, heats and stirs with oil bath on constant temperature magnetic heating stirrer to boiling (100 ℃), the process is equipped with a cooling reflux device;

[0025] (2) Titanium sulfate is added to hydrochloric acid (volume ratio is 1:1 (concentrated hydrochloric acid: water)) according to the solid-liquid ratio of 1:18.75 (g / ml) and dissolved for later use;

[0026] (3) Use a constant flow pump to add hydrochloric acid and a certain amount of titanium sulfate mixed solu...

Embodiment 2

[0029] Example 2 A high-efficiency titanium-doped birnessite material for antimony removal is synthesized from potassium permanganate and titanium sulfate at a mass ratio of 6.59:1 (ie molar ratio Ti / Mn=1:10).

[0030] A method for preparing titanium-doped birnessite that can efficiently remove trivalent antimony as described above comprises the following steps:

[0031] (1) Potassium permanganate is 1:9.5-10.5 (g / ml) is placed in the Erlenmeyer flask that adds deionized water according to material-liquid ratio, heats and stirs with oil bath on constant temperature magnetic heating stirrer to boiling (100 ℃), the process is equipped with a cooling reflux device;

[0032] (2) Titanium sulfate is added to hydrochloric acid (volume ratio is 1:1 (concentrated hydrochloric acid: water)) according to the solid-liquid ratio of 1:9.38 (g / ml) and dissolved for later use;

[0033] (3) Use a constant flow pump to add hydrochloric acid and a certain amount of titanium sulfate mixed solut...

Embodiment 3

[0036] Example 3 A high-efficiency titanium-doped birnessite material for antimony removal is synthesized from potassium permanganate and titanium sulfate at a mass ratio of 3.3:1 (ie molar ratio Ti / Mn=1:5).

[0037] A method for preparing titanium-doped birnessite that can efficiently remove trivalent antimony as described above comprises the following steps:

[0038] (1) Potassium permanganate is 1:9.5-10.5 (g / ml) is placed in the trivalent flask that adds deionized water according to material-liquid ratio, heats and stirs with oil bath on constant temperature magnetic heating stirrer until boiling ( 100°C), the process is equipped with a cooling reflux device;

[0039] (2) Titanium sulfate is added to hydrochloric acid (volume ratio is 1:1 (concentrated hydrochloric acid: water)) according to the solid-liquid ratio of 1:4.69 (g / ml) and dissolved for later use;

[0040] (3) Use a constant flow pump to add hydrochloric acid and a certain amount of titanium sulfate mixed solu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com