Method for preparing plastic warm-stirred modified asphalt mixture

A manufacturing method and technology of modified asphalt, which is applied in the field of manufacturing plastic warm-mix modified asphalt mixture, can solve problems such as asphalt prone to aging, achieve reduced asphalt smoke emissions, high temperature resistance to rutting, and increase service life and road performance effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

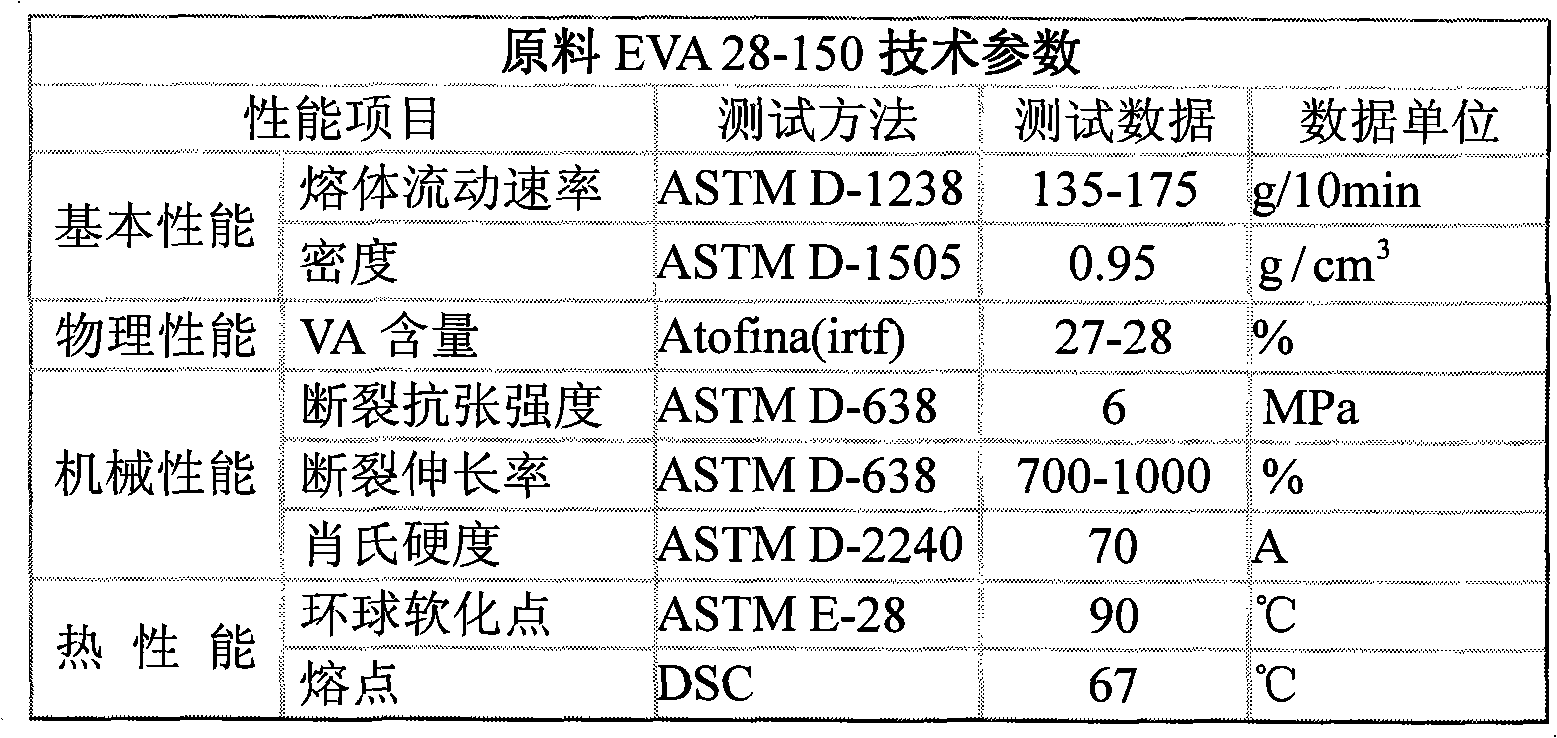

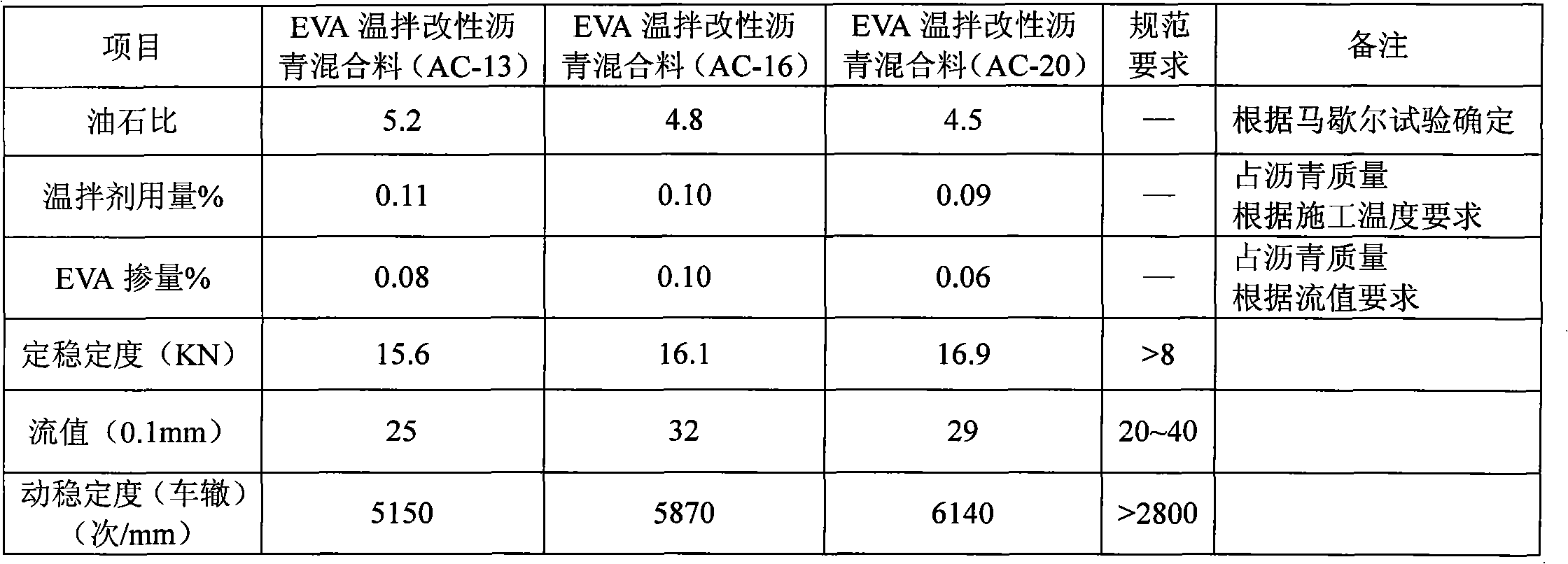

[0027] The performance indexes of the EVA warm-mix modified asphalt mixture of the present invention are shown in Table 1, and the performance indexes of the EVA warm-mix modified asphalt mixture AC-13 are compared with ordinary warm-mix modified asphalt in Table 2.

[0028] Table 1 Performance indicators of EVA warm mix modified asphalt mixture

[0029]

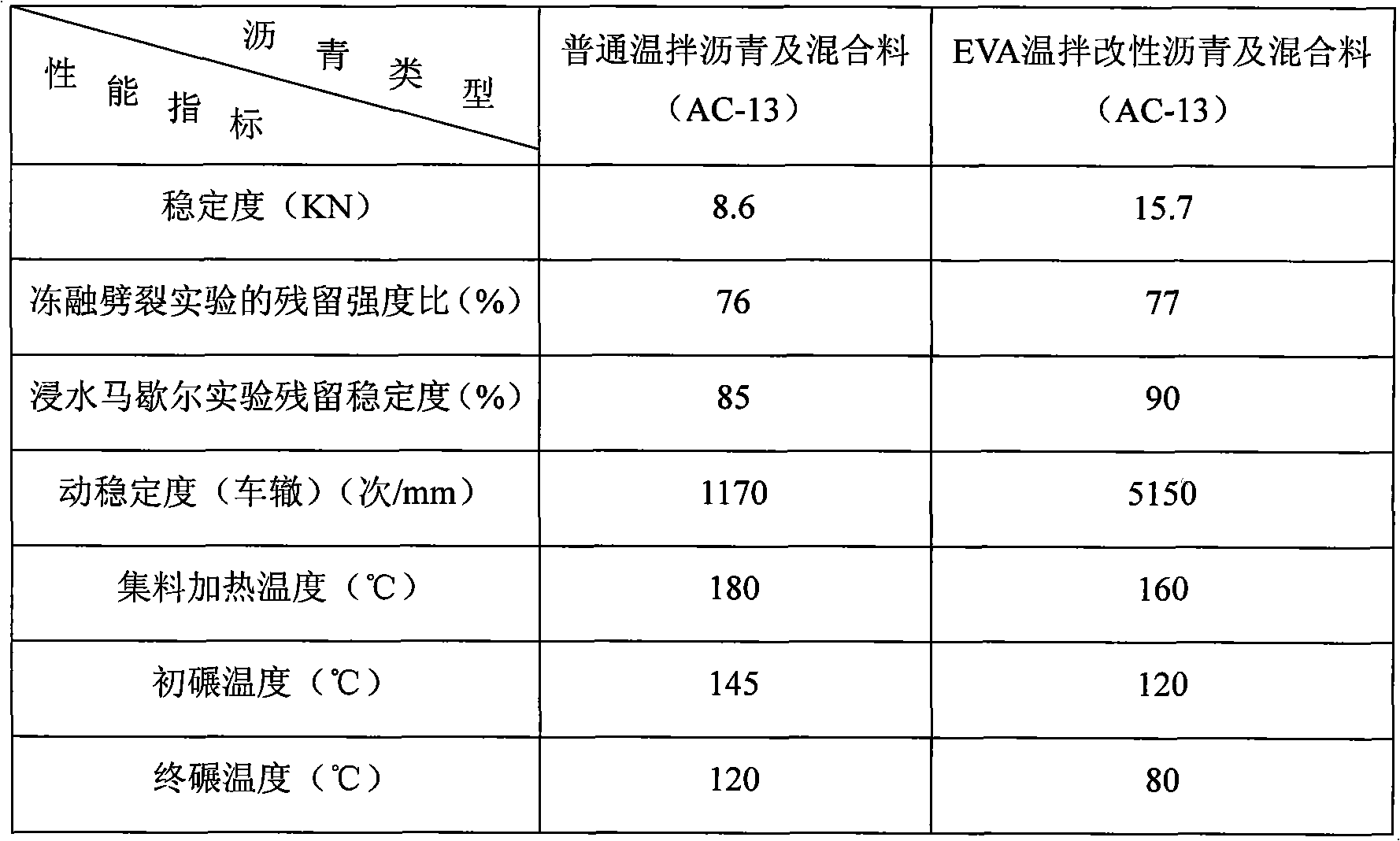

[0030] Table 2 Comparison table of various performance indicators of AC-13 mixture

[0031]

[0032] Note: The asphalt used in the experiments in this table is 70 # Heavy traffic asphalt, aggregate gradation is AC-13.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com