Warm mixed asphalt cement and preparation method thereof

A technology for warm mix asphalt and cementitious materials, which is applied to building thermal insulation materials, coagulating pavements laid on site, building components, etc. Insufficient and other problems, to achieve the effect of improving low-temperature tensile and brittle resistance, improving high-temperature rutting resistance, and improving construction and workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

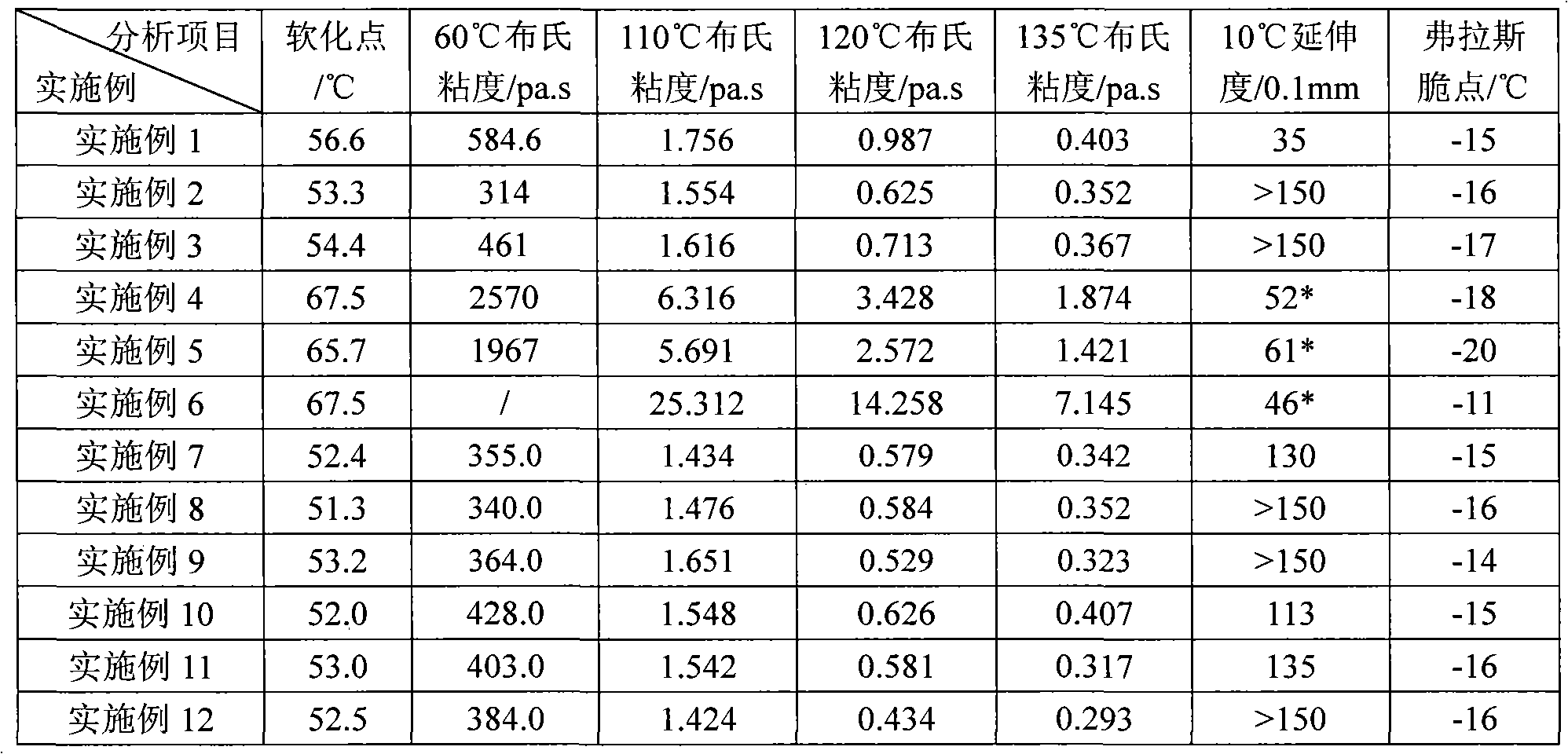

Examples

Embodiment 1

[0030] a) Weigh No. 50 base asphalt accounting for 95.0w% of the warm-mix asphalt binder, slowly heat it to 150°C, and keep the temperature until it is completely melted, add 0.5w% of the warm-mix asphalt binder to extract oil, 0.5 w% coker wax oil, 1.0w% petroleum resin, 1.0w% stearyl alcohol, 1.0w% stearyl stearate, stir until uniform; b) weigh 1.0w% SBS polymer accounting for warm mix asphalt binder The modifier is added in batches to the mixing system of the above-mentioned base asphalt and the rheology modifier, sheared and stirred until the polymer particles are evenly distributed within the range of <100 μm. c) Slowly raise the temperature to 180°C, stir and react for 2 hours and take out of the pot.

Embodiment 2

[0032] a) Weigh No. 70 base asphalt accounting for 95.0w% of the warm-mix asphalt binder, slowly heat it to 150°C, and keep the temperature constant until it is completely melted, add 0.5w% of the warm-mix asphalt binder to extract oil, 0.5 w% vacuum distillate oil, 1.0w% montan wax, 1w% petroleum resin, 1.0w% pentaerythritol stearate, stir until uniform; b) weigh 1.0w% butadiene rubber BR modification of warm mix asphalt binder agent, added in batches to the mixing system of the above-mentioned base asphalt and rheology modifier, sheared and stirred until the polymer particles are evenly distributed within the range of <100 μm. c) Slowly raise the temperature to 170°C, stir and react for 2 hours and take out of the pot.

Embodiment 3

[0034] a) Weigh No. 90 matrix asphalt accounting for 95.0w% of the warm-mix asphalt binder, slowly heat it to 150°C, and keep the temperature constant until it is completely melted, add 0.5w% of the warm-mix asphalt binder FCC oil slurry, 0.5w% coker wax oil, 1w% Sasobit, 1.0w% stearic acid, 1.0w% ethylene-vinyl acetate, stir until uniform; b) Weigh 1.0w% SBR polymer modifier in warm mix asphalt binder , added in batches to the mixing system of the above-mentioned base asphalt and rheology modifier, sheared and stirred until the polymer particles are evenly distributed within the range of <100 μm. c) Slowly raise the temperature to 180°C, stir and react for 1 hour and take out of the pot.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com