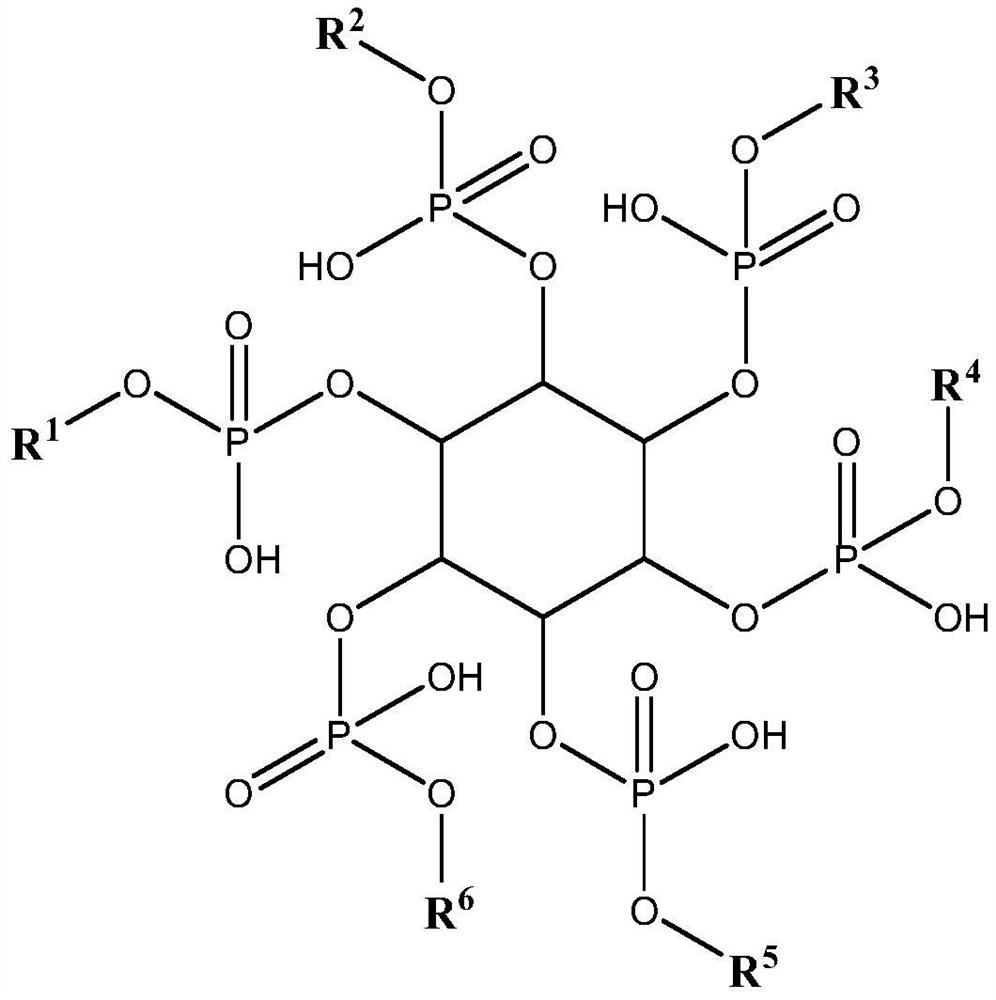

Polyphosphate compound as well as preparation method and application thereof

A polyphosphoric acid and compound technology, applied in the field of concrete admixtures, can solve the problems of reducing the sensitivity of concrete, poor workability, etc., and achieve the effects of improving the performance of hardened concrete, simple and feasible process, and improving workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

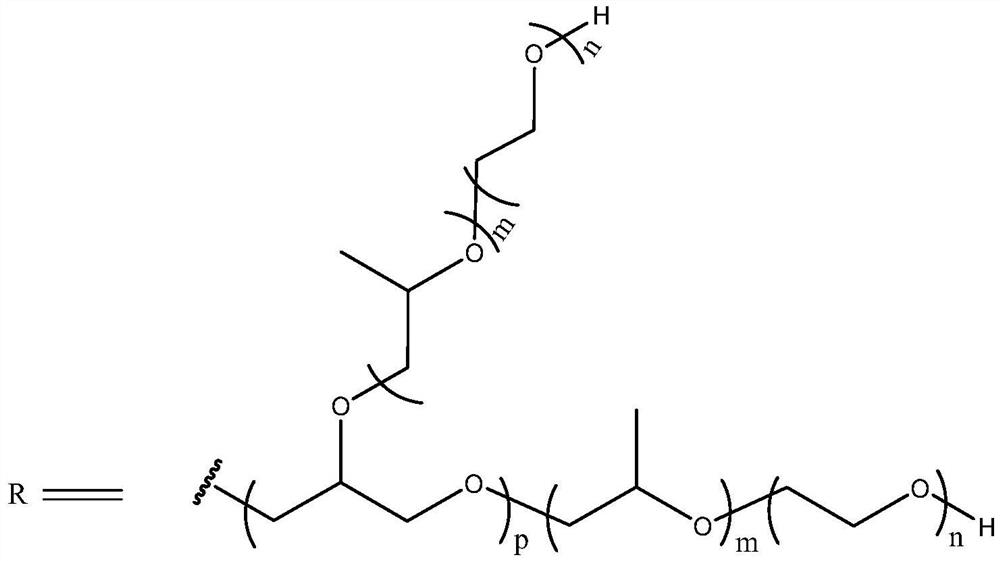

[0056] (1) Preparation of polyether

[0057] In a 500mL three-necked flask, add 1.0mol of ethylene glycol and 0.05mol of triethylamine, keep the temperature at 40-60°C, slowly add 1.0mol of benzyl chloride (BnCl) dropwise, and keep it for 1.0h after the addition is complete;

[0058] In a 1000mL autoclave, add 0.1mol of ethylene glycol with one-end hydroxyl protected and 0.006mol of sodium methoxide, slowly heat to 50-60°C, evacuate to -0.08MPa, keep for 30min, slowly add 0.20mol of glycidol, and react After 20 minutes of aging, 0.30 mol of propylene oxide was introduced, and after 20 minutes of aging, ethylene oxide was continuously introduced to keep the reaction pressure at 0.2-0.3 MPa and the reaction temperature at 110-120°C. Add 4.34 mol of ethylene oxide in total. Heat preservation and aging reaction for 30 minutes, degassing, discharge, GPC test: weight average molecular weight Mw = 2200;

[0059] In a 1000mL three-necked bottle, transfer the newly prepared polyether,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com