Ultrasonic variable frequency compound precipitation method

An ultrasonic and pumping well technology, which is applied in construction and infrastructure engineering, etc., can solve the problems of small flow rate and the uniformity of flow rate structure, and achieve the effects of increased drainage, low cost, and shortened precipitation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

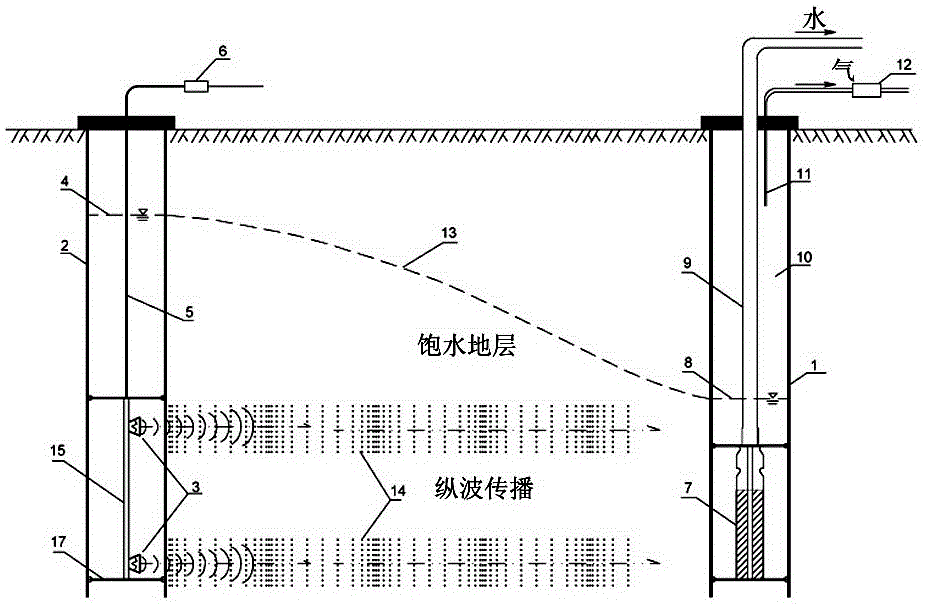

[0016] Such as Figure 1-2 As shown, the ultrasonic frequency conversion composite dewatering method of the present invention is carried out according to the following steps: (the following pumping wells and launching wells are multiple, for ease of description, a pumping well and a launching well are taken as an example below for description. )

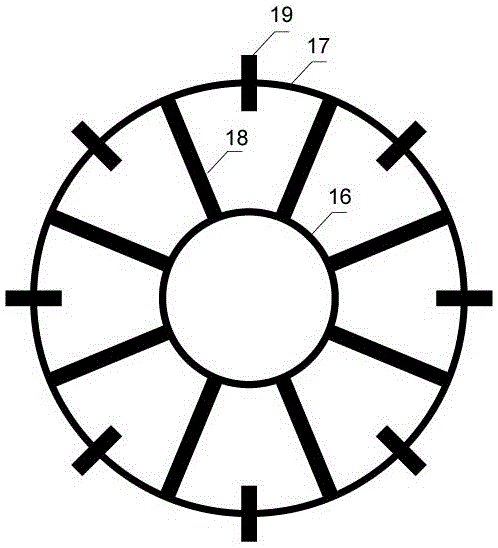

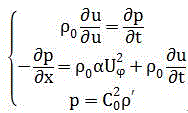

[0017] The first step is to set up pumping well 1 and launching well 2 in the area where precipitation treatment is required; the oscillation frequency of the ultrasonic generator is consistent with the frequency of the ultrasonic pulse signal sent by the pulse signal control device. The formation characteristic parameters are calculated; the shape of the ultrasonic generator can be selected as a rectangular plate, a semicircle, a cylinder or a point piece linear body according to actual needs;

[0018] In the second step, the first vertical lifting device is set in the launch shaft 2, and the ultrasonic generator 3 is placed at the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com