Fluorescent oil-base magnetic suspension for magnetic particle inspection, and preparation method thereof

A technology of magnetic particle flaw detection and fluorescent oil, which is applied in the direction of material magnetic variable, etc., can solve problems such as unavailable, difficult to control the concentration and suspension of the proportion, troublesome testing personnel, etc., and achieve long suspension time, good suspension, and dispersion good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

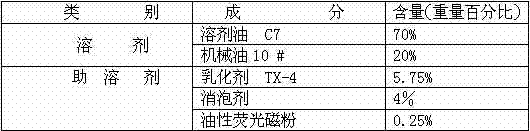

[0023] A typical formulation of the present invention is as follows:

[0024]

[0025] Its preparation method is as follows:

[0026] (1) At room temperature, mix and stir the co-solvent evenly and place it for 10 hours for use, and mix and stir the solvent and surfactant for 1 hour before use;

[0027] (2) Add the co-solvent mixture into the solvent mixture, and then stir for 0.5 hours;

[0028] (3) Then add the magnetic powder mixture into the liquid and stir for 1.5 hours, then filter with 200-mesh gauze to remove the residue.

[0029] The concentration of the magnetic suspension after filtering out the residue is 0.1% to 0.25%; the corrosion test of the suspension is carried out with samples of aluminum-magnesium alloy, steel, and stainless steel, and there should be no rust within 24 hours; the prepared suspension liquid, put it into the aerosol tank with the aerosol filling production line, the pressure in the tank is 2.5-4.5Kg / cm 2 。

Embodiment 2

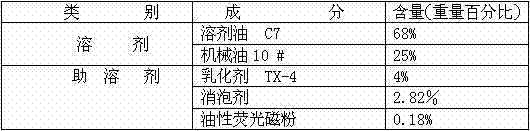

[0031] Another typical formula of the present invention is as follows:

[0032]

[0033] Its preparation method is with embodiment one

Embodiment 3

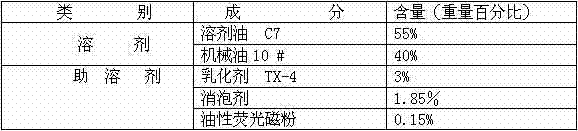

[0035] The present invention also has a typical formula as follows:

[0036]

[0037] Its preparation method is with embodiment one

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com