Devices for filling and/or closing containers with drive shaft purge cartridges

A technology for closing containers and driving shafts, applied in the directions of bottle/container caps, closures, transportation and packaging, etc., can solve the problems of gas outflow, inflow, cap, bottle product pollution, etc., and achieve the effect of good environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

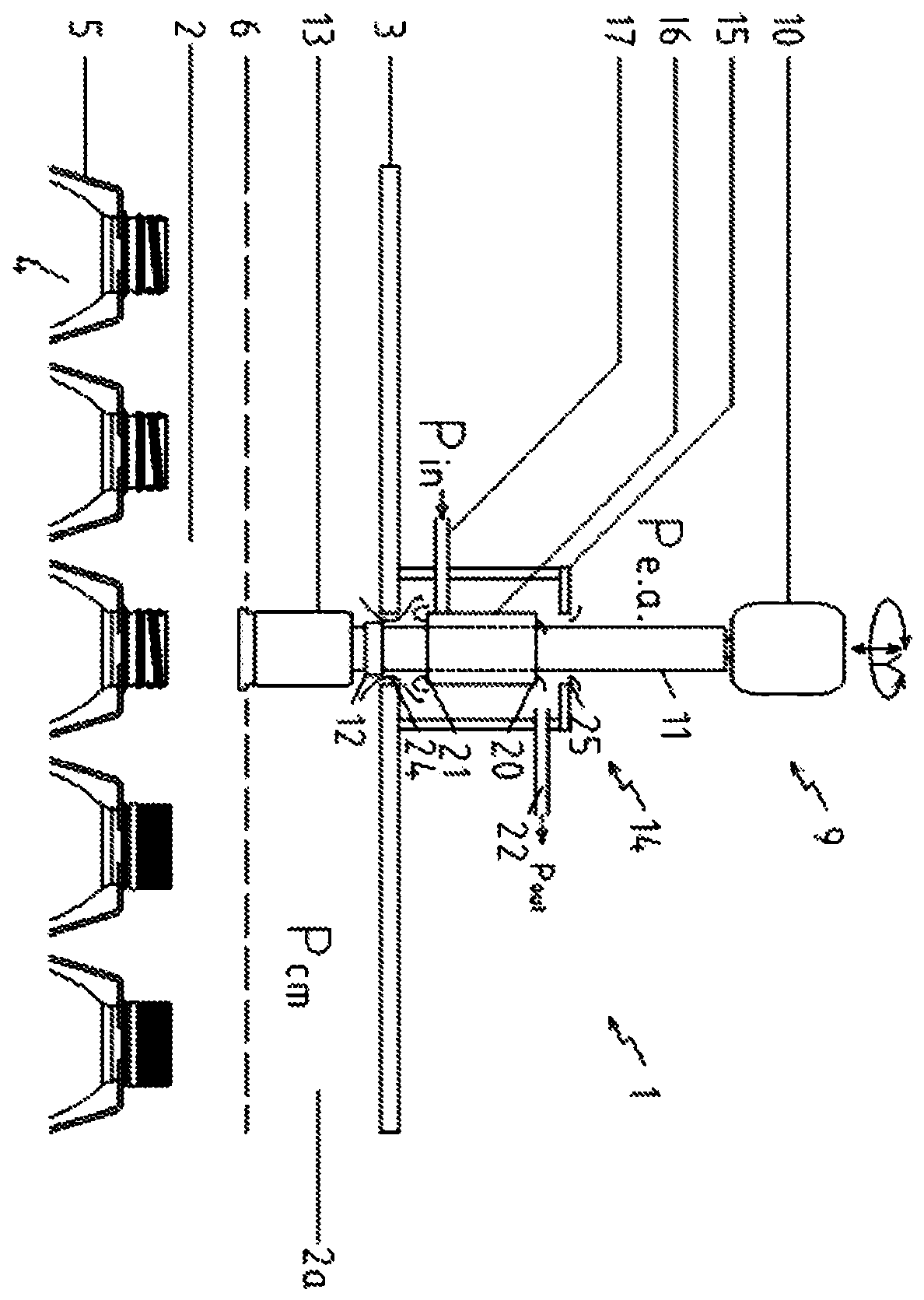

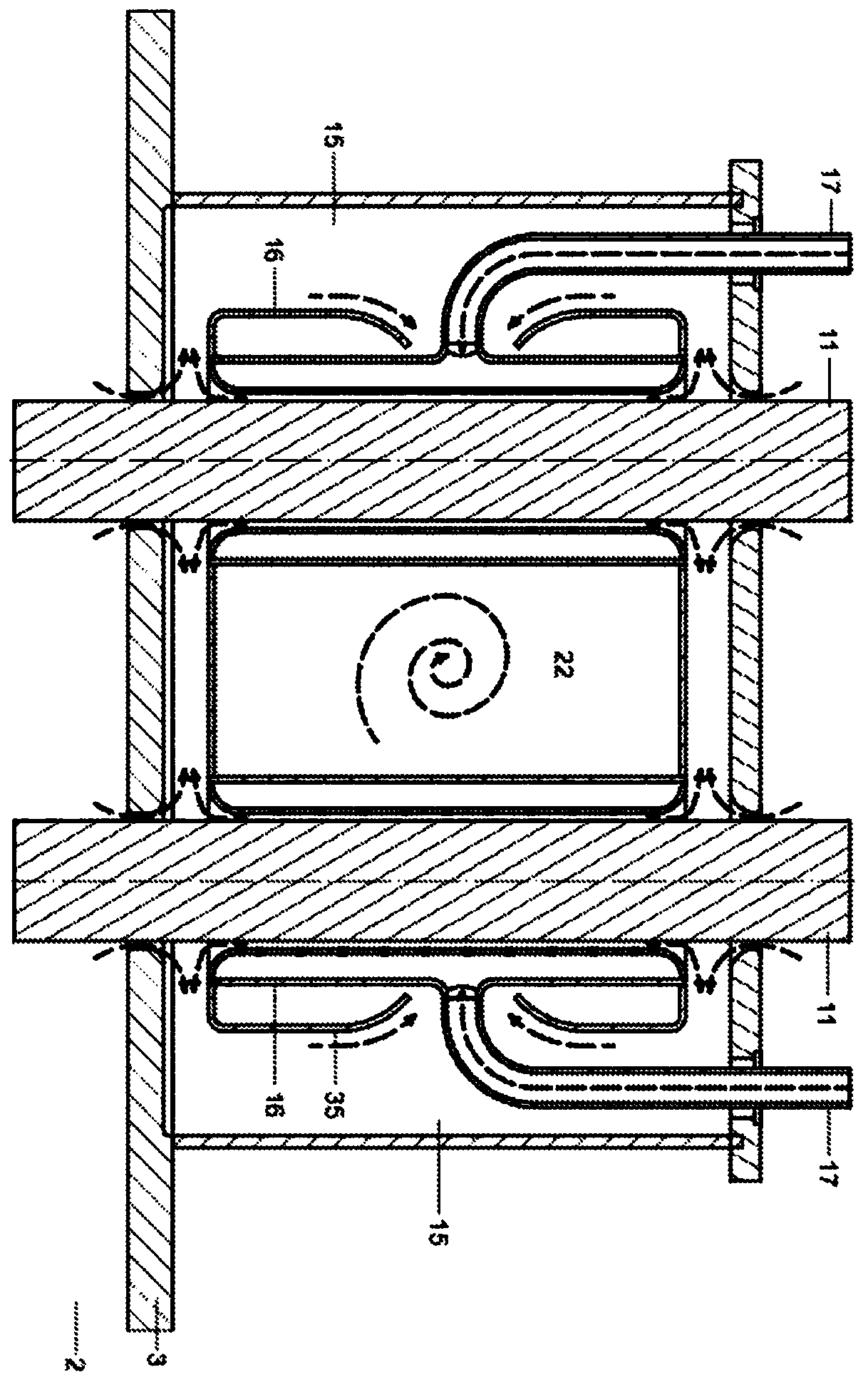

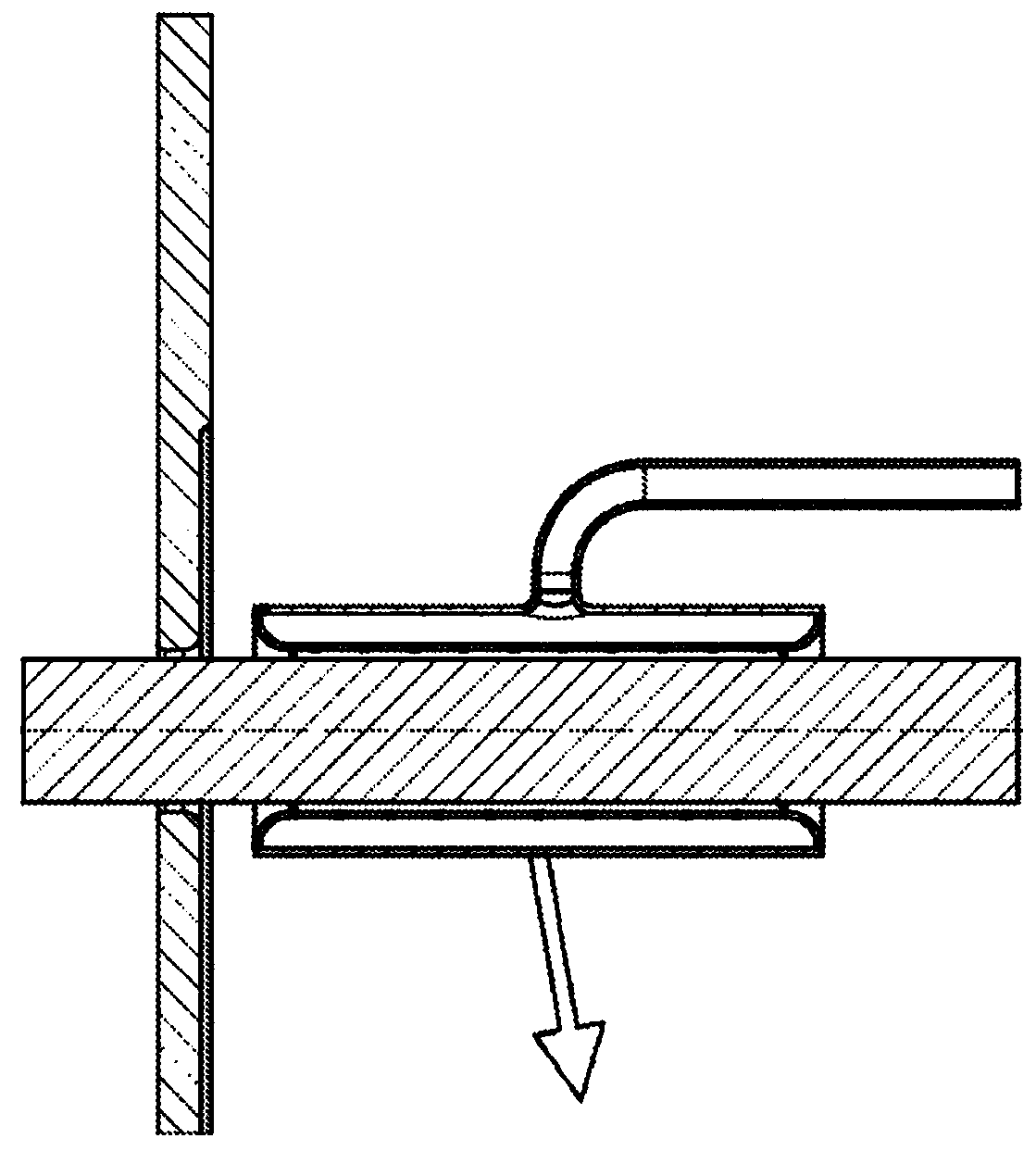

[0030] exist figure 1 , reference numeral 1 denotes the entire device. The device 1 comprises a sterile area 2 which is bounded on its upper side by a ceiling 3 . The bottles 4 are transported with their upper ends through the region 2 by means of bottle holders 5 . During operation, conditioning medium is supplied into the zone 2 by a conditioning medium supply (not shown) connected to the upper part 2 a of the zone 2 . A grid plate 6 is provided to distribute the regulating medium evenly in the entire working area 2 at the upper end of the bottle body 4 .

[0031] On top of the device 1 , in the environment outside the conditioned area 2 , a cap unit 9 is mounted. The unit 9 comprises a servo drive unit 10 enabling the drive shaft 11 to move up and down along the y-axis and also to turn it around the y-axis in order to place and screw on the bottle body 4 a suitable cap, cap, etc. To this end, the drive shaft 11 is provided at its lower end with an operator 12 connectabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com