Energized water-based fracturing fluid as well as preparation method and application thereof

A water-based fracturing and energizing technology, applied in chemical instruments and methods, earth-moving drilling, wellbore/well components, etc., can solve the problems of complex operation, shortened construction period, long construction time, etc., to improve strength , The effect of shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

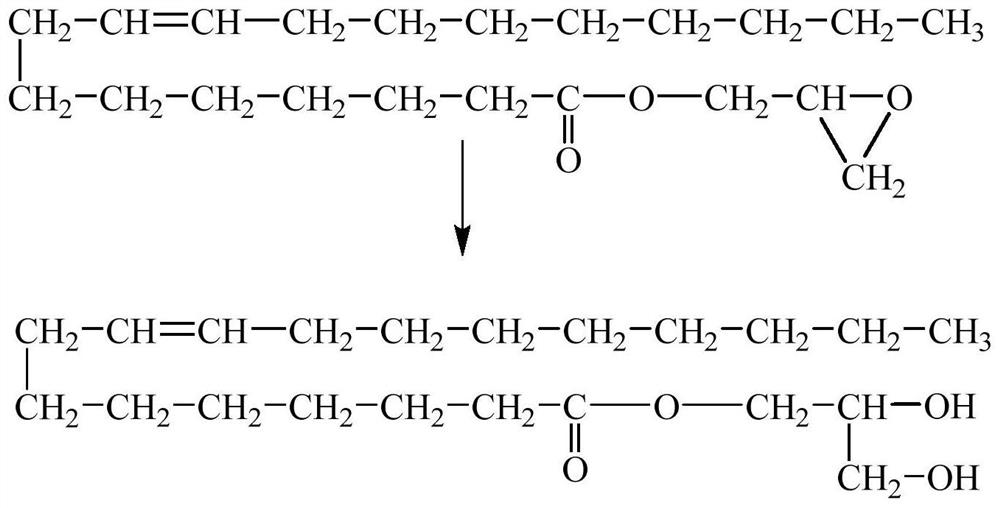

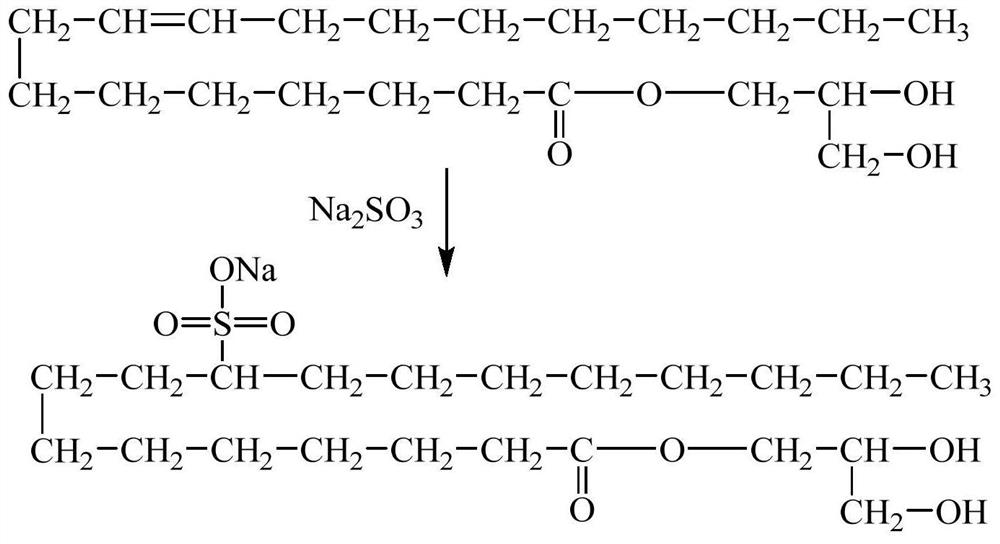

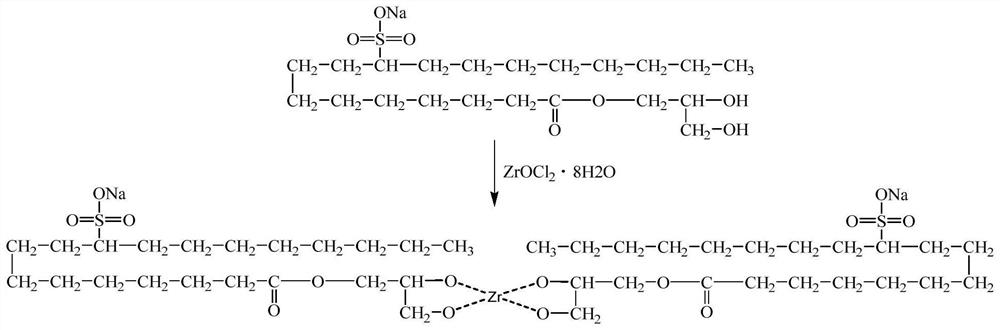

[0045] The specific preparation process of an energized water-based fracturing fluid is realized by the following reactions:

[0046]

[0047] Specifically, a preparation method of an enabling type water-based fracturing fluid of the present invention includes the following steps:

[0048] 1) Add a certain amount of N,N-dimethylformamide as a solvent to the three-necked reaction flask equipped with the condensation reflux device, and then add a certain amount of acrylic acid-2,3-epoxypropyl octadecenoic acid and acetic acid As a solute, the reaction is carried out at a certain temperature for a certain period of time; the reaction is a ring-opening reaction; the mass ratio of acetic acid to 2,3-glycidyl acrylate octadecenoic acid is (1-2): 1; the mass fraction of the solute is 32-34wt%; the reaction temperature is 50-100°C; the reaction time is 0.5-3h.

[0049] 2) The reaction product is treated with distilled water of equal volume with the solution, so that unreacted acetic...

Embodiment 1

[0062] The constant temperature magnetic stirring oil bath was preheated, and 75g of N,N-dimethylformamide was added as a solvent to the three-necked reaction flask equipped with the condensation reflux device, and then 12g of acrylic acid-2,3-epoxypropyl was added. Octadenoic acid and 25g acetic acid were reacted at 100°C for 0.5h; the reaction product was treated with an equal volume of distilled water, so that the unreacted acetic acid and solvent N,N-dimethylformamide entered the water phase, cooled to room temperature, washed with water and suction filtered Twice to obtain solid intermediate monomer I; take 15g of sodium bisulfite mixed with water, add 10g of monomer I, simultaneously add 10g of 30% hydrogen peroxide as a catalyst, add in a three-necked reaction flask equipped with a condensation reflux device, and react at 60°C 1h; after the reaction, it was cooled to below 36°C, washed with water and filtered twice to obtain powdery intermediate monomer II; 1.5 g of zirc...

Embodiment 2

[0064] The constant temperature magnetic stirring oil bath was preheated, and 62g of N,N-dimethylformamide was added to the three-necked reaction flask equipped with the condensation reflux device as a solvent, and then 12.6g of acrylic acid-2,3-epoxypropylene was added. Esteroctadecenoic acid and 18 g acetic acid were reacted at 100 °C for 1 h; the reaction product was treated with an equal volume of distilled water, so that unreacted acetic acid and solvent N,N-dimethylformamide entered the water phase, cooled to room temperature, washed with water and suction filtered Twice to obtain solid intermediate monomer I; take 18g of sodium bisulfite mixed with water, add 10g of monomer I, add 10g of 30% hydrogen peroxide as a catalyst, add a three-necked reaction flask equipped with a condensation reflux device, and react at 60 ° C 1h; after the reaction was completed, it was cooled to below 36°C, washed with water and filtered twice to obtain powdery intermediate monomer II; the zi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com