Asphalt high-ductility cementing material, high-ductility material and preparation method

A high ductility, bitumen technology, used in building thermal insulation materials, building components, buildings, etc., can solve the problems of long maintenance time, easy recurrence of diseases, and high maintenance costs, so as to improve driving comfort and temperature sensitivity. , the effect of improving tensile properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

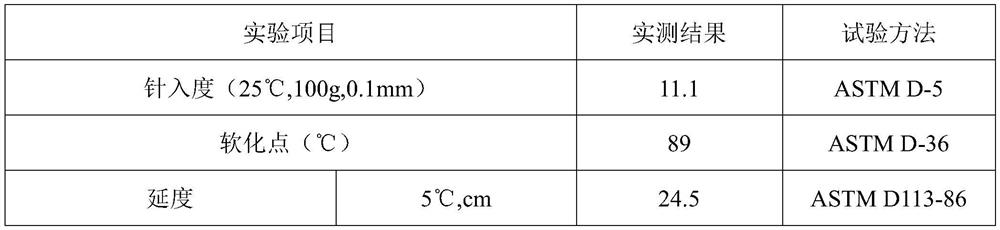

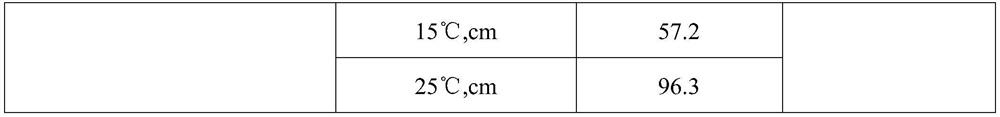

Embodiment 1

[0039] A kind of preparation method of bituminous high ductility material, it comprises the following steps

[0040] (1) Preparation of asphalt-based high-ductility binder:

[0041] a Calculate the total mass of asphalt-like high-ductility materials that need to be prepared (about 450g each time is advisable);

[0042] b According to the total mass of bituminous high-ductility materials calculated in step a and the blending ratio between various materials, calculate the required (matrix) bitumen 90.570%, thermoplastic resin 7.580%, viscous resin 0.362%, EVA0 .723%, zinc stearate 0.036%, antioxidant 0.004%, plasticizer 0.125%, crosslinking agent 0.600%;

[0043] c. First add thermoplastic resin, viscous resin and EVA into the high-speed mixer, and mix evenly to obtain the first material;

[0044]D zinc stearate, antioxidant, plasticizer are added in the first material, mix to obtain the second material;

[0045] e granulating and cutting the second material to obtain the thi...

Embodiment 2

[0062] A preparation method of bituminous high ductility material, it comprises the following steps:

[0063] (1) Preparation of asphalt-based high-ductility binder:

[0064] a Calculate the total mass of asphalt-like high-ductility materials that need to be prepared (about 450g each time is advisable);

[0065] b According to the total mass of bituminous high-ductility materials calculated in step a and the blending ratio between various materials, calculate the required (matrix) bitumen 90.570%, thermoplastic resin 7.580%, viscous resin 0.362%, EVA0 .723%, zinc stearate 0.036%, antioxidant 0.020%, plasticizer 0.109%, crosslinking agent 0.600%;

[0066] c. First add thermoplastic resin, viscous resin and EVA into the high-speed mixer, and mix evenly to obtain the first material;

[0067] D zinc stearate, antioxidant, plasticizer are added in the first material, mix to obtain the second material;

[0068] e granulating and cutting the second material to obtain the third mat...

Embodiment 3

[0081] A preparation method of bituminous high ductility material, it comprises the following steps:

[0082] (1) Preparation of asphalt-based high-ductility binder:

[0083] a Calculate the total mass of asphalt-like high-ductility materials that need to be prepared (about 450g each time is advisable);

[0084] b According to the total mass of bituminous high-ductility materials calculated in step a and the blending ratio between various materials, calculate the required (matrix) bitumen 90.570%, thermoplastic resin 7.580%, viscous resin 0.362%, EVA0 .723%, zinc stearate 0.043%, antioxidant 0.013%, plasticizer 0.109%, crosslinking agent 0.600%;

[0085] c. First add thermoplastic resin, viscous resin and EVA into the high-speed mixer, and mix evenly to obtain the first material;

[0086] D zinc stearate, antioxidant, plasticizer are added in the first material, mix to obtain the second material;

[0087] e granulating and cutting the second material to obtain the third mat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com