Ferronickel slag fiber stabilizer as well as preparation method and application thereof

A technology of fiber stabilizer and ferronickel slag, which is applied in the field of comprehensive utilization of non-ferrous metal smelting solid waste, can solve the problems of unsuitable fiber stabilizer for road use, poor interface compatibility, insufficient flexibility, etc., to improve high temperature anti-rutting ability, Improved low-temperature cracking resistance and widened the range of options

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

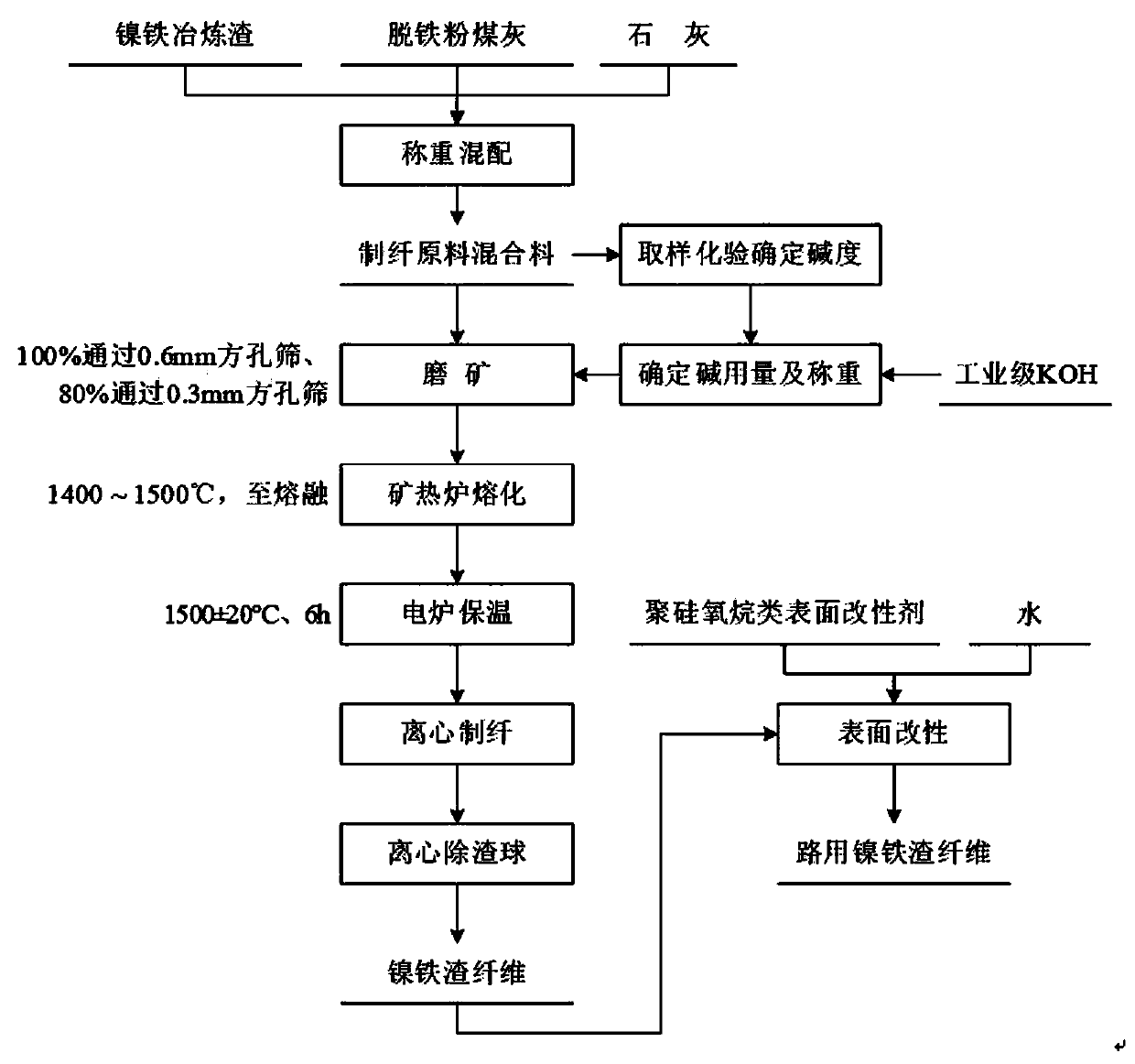

[0065] Firstly, mix ferronickel slag, de-ironized fly ash and lime according to 54%: 28%: 18%, grind until 100% pass through 0.6mm, 80% pass through 0.3mm square hole sieve; sampling raw material mixture for composition Laboratory analysis, according to the results, use KOH to adjust the alkalinity of the raw material mixture to 0.58; send the above-mentioned pretreated raw materials to the submerged arc furnace for melting, set the melting temperature at 1500°C to completely melt, put the slag into the electric heating In the holding furnace, keep warm at 1520°C for 6 hours, put the slag into the centrifugal fiber forming machine; finally, remove the slag balls, collect fibers, and chop through centrifugation, and then modify the surface, the activation index is 0.75, and the fiber produced is single The wire diameter is 6.4 μm, the single wire breaking strength is 1320 MPa, and the shot content is 4.8% (percentage by weight).

[0066] According to the industry standard of th...

Embodiment 2

[0068] Firstly, mix ferronickel slag, de-ironized fly ash and lime according to 62%: 22%: 16%, grind until 100% pass through 0.6mm, 80% pass through 0.3mm square hole sieve; sampling raw material mixture for composition Laboratory analysis, according to the results, use KOH to adjust the alkalinity of the raw material mixture to 0.55; send the above-mentioned pretreated raw materials to the submerged arc furnace for melting, and set the melting temperature to 1500 ° C to completely melt, and put the slag to Electric heat preservation furnace, heat preservation at 1520°C for 6 hours, put the slag into the centrifugal fiber machine; finally, remove the slag ball, collect the fiber, chop, and then modify the surface, the activation index is 0.71, and the fiber produced The diameter of the single filament is 8.2 μm, the breaking strength of the single filament is 1336 MPa, and the content of slag is 3.2% (percentage by weight).

[0069] According to the industry standard of the Pe...

Embodiment 3

[0071] Firstly, mix ferronickel slag, de-ironized fly ash and lime according to 46%: 32%: 22%, grind until 100% pass through 0.6mm, 80% pass through 0.3mm square hole sieve; sampling raw material mixture for composition Laboratory analysis, according to the results, use KOH to adjust the alkalinity of the raw material mixture to 0.62; send the above-mentioned pretreated raw materials to the submerged arc furnace for melting and send them to the submerged arc furnace for melting, and the melting temperature is set at 1400 ° C to fully melt , put the molten slag into the electric heat preservation furnace, heat it at 1480°C for 6 hours, put the molten slag into the centrifugal fiber forming machine; finally, remove the slag ball, collect the fiber, chop, and then modify the surface, the activation index is 0.71, the fiber monofilament diameter is 7.5 μm, the monofilament breaking strength is 1219 MPa, and the shot content is 4.8% (weight percentage).

[0072] According to the in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

| activation index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com