Organic composite nanometer modified asphalt additive and preparation method and application thereof

A kind of asphalt additive and nano-modification technology, which is applied in the direction of building components, building insulation materials, buildings, etc., can solve the problems of lowering the construction temperature, and achieve the effects of avoiding waste, improving the performance of modified asphalt, and mature production technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

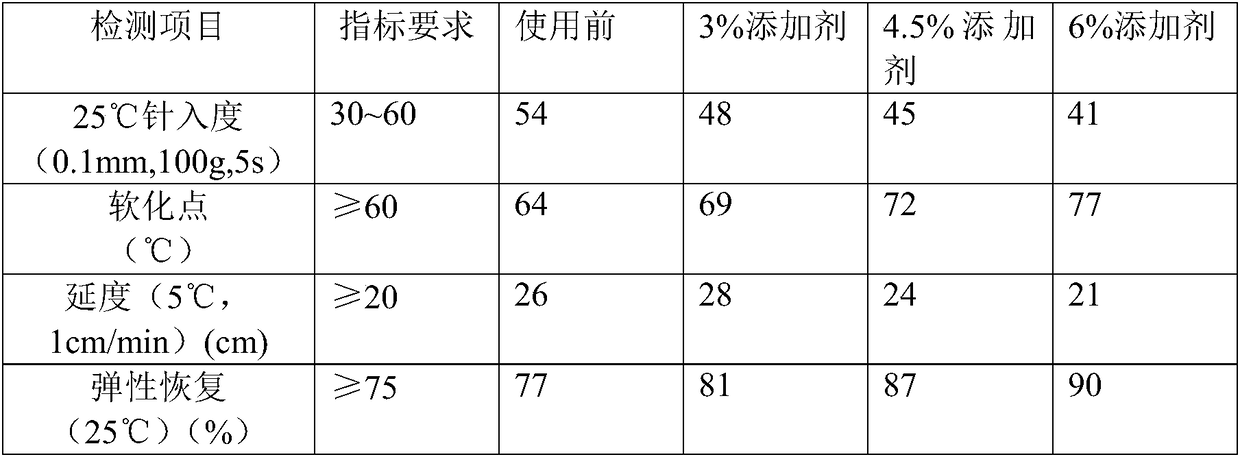

Embodiment 1

[0023] Example 1 An organic nanocomposite modified asphalt additive is composed of the following raw materials in parts by mass: 100 parts of nano powder, 30 parts of SLD wax, and 30 parts of plasticizer; the nano powder is nano-montmorillonite, The SLD base wax is preferably an alkane wax synthesized from hydrocarbon-based synthesis gas and natural gas based on the Fischer-Tropsch process, with a softening point of 95-110°C, and the plasticizer is dioctyl phthalate (DOP).

[0024] The preparation method of this example additive comprises the steps:

[0025] 1. Dry 100 parts of nano-montmorillonite until the moisture content is not greater than 0.05%;

[0026] 2. Heat 30 parts of dioctyl phthalate (DOP) to 120-130 ° C, add 29.34 parts of Fischer-Tropsch wax, 0.6 parts of MAH, and 0.06 parts of DTBP in sequence, and continue to heat up to 130 ± 1 during stirring SLD wax solution was obtained at 5°C.

[0027] 3. The liquid obtained in step 2 is atomized and sprayed into the na...

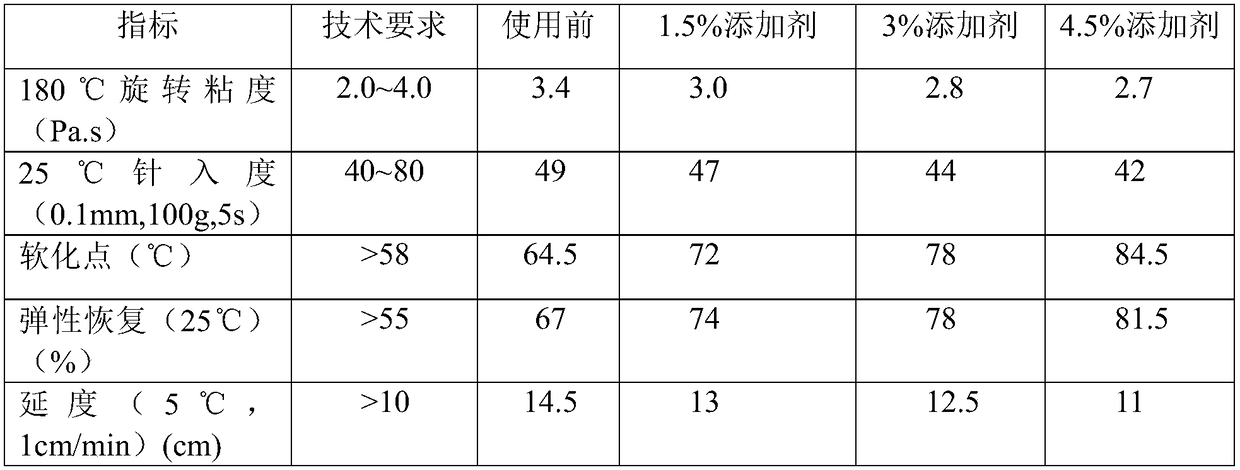

Embodiment 2

[0029] Example 2 An organic nanocomposite modified asphalt additive is composed of the following raw materials in parts by mass: 100 parts of nano powder, 45 parts of SLD wax, and 45 parts of plasticizer; the nano powder is nano calcium carbonate, SLD The base wax is preferably an alkane wax synthesized from hydrocarbon-based synthesis gas and natural gas based on the Fischer-Tropsch process, with a softening point of 95-110°C, and the plasticizer is epoxy fatty acid methyl ester.

[0030] The preparation method of this example additive comprises the steps:

[0031] 1. Dry 100 parts of nano-montmorillonite until the moisture content is ≯0.05%;

[0032] 2. Heat 45 parts of epoxy fatty acid methyl ester to 120-130°C, add 44 parts of Fischer-Tropsch wax, 0.9 part of MAH, and 0.09 part of DTBP in sequence, and continue to heat up to 130±5°C during stirring to obtain SLD wax liquid.

[0033] 3. The liquid obtained in step 2 is atomized and sprayed into the nano-calcium carbonate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com