Anti-rut agent and preparation method therefor

A technology of anti-rutting agent and sulfur stabilizer, applied in the field of pavement materials, can solve the problems of increased construction control difficulty, pollution discharge, prolonged mixing time, low anti-rutting effect, etc., and achieves easy control of construction process, improved softening point, and improved mixing. short time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] An anti-rutting agent consisting of the following components:

[0027] Synthetic rubber: 40Kg;

[0028] Sulfur stabilizer: 10Kg. `

[0029] The preparation method of above-mentioned anti-rutting agent: comprise the following steps:

[0030] ⑴. Grinding 40Kg of synthetic rubber to a fineness of 75 mesh;

[0031] ⑵. Add the crushed synthetic rubber and 10Kg of sulfur stabilizer to 40Kg of ferric chloride solution;

[0032] ⑶. Stir evenly at room temperature to make anti-rutting agent.

Embodiment 2

[0034] An anti-rutting agent consisting of the following components:

[0036] Synthetic rubber: 45Kg;

[0037] Sulfur stabilizer: 11Kg. `

[0038] The preparation method of above-mentioned anti-rutting agent: comprise the following steps:

[0039] ⑴. Grinding 45Kg of synthetic rubber to a fineness of 50 mesh;

[0040] (2) Add the crushed synthetic rubber and 11Kg of sulfur stabilizer to 45Kg of ferric chloride solution;

[0041] ⑶. Stir evenly at room temperature to make anti-rutting agent.

Embodiment 3

[0043] An anti-rutting agent consisting of the following components:

[0044] Ferric chloride: 50Kg;

[0045] Synthetic rubber: 50Kg;

[0046] Sulfur stabilizer: 12Kg. `

[0047] The preparation method of above-mentioned anti-rutting agent: comprise the following steps:

[0048] ⑴. Grinding 50Kg of synthetic rubber to a fineness of 80 mesh;

[0049] ⑵. Add the crushed synthetic rubber and 12Kg of sulfur stabilizer to 50Kg of ferric chloride solution;

[0050] ⑶. Stir evenly at room temperature to make anti-rutting agent.

[0051] The anti-rutting agent of the present invention has the following advantages:

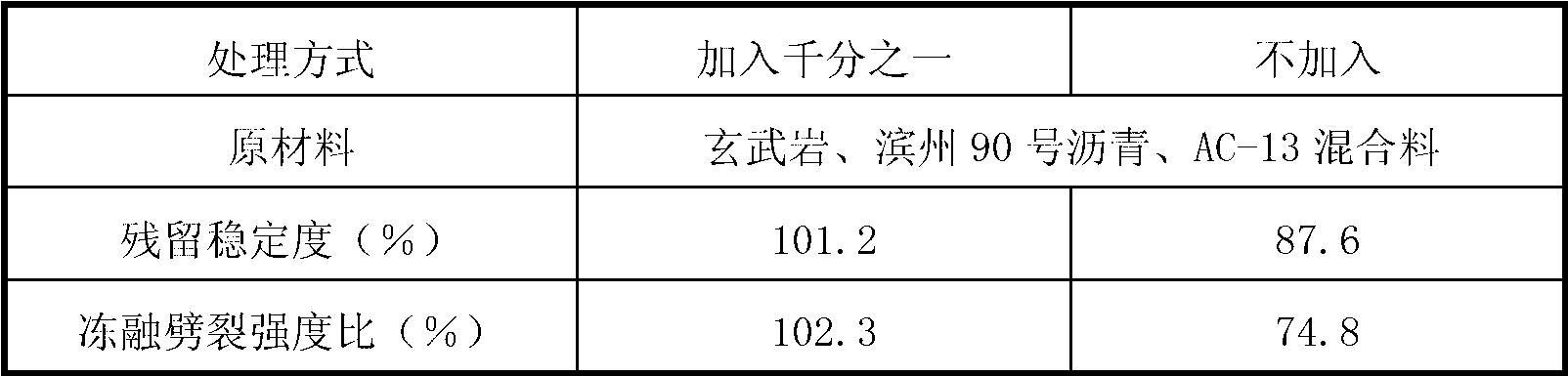

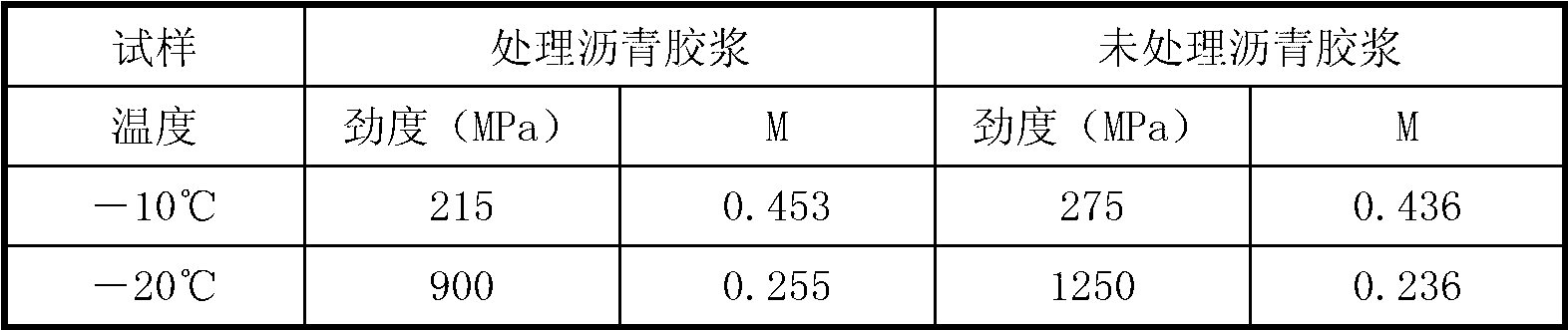

[0052] 1. Higher cost performance: Only 0.1% to 0.3% of 1518 anti-rutting agent needs to be added to ordinary asphalt mixture, which can significantly improve the high temperature resistance of asphalt mixture, and improve the resistance to water damage and low temperature cracking Wait.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com