Warm mix type high modulus asphalt mixture additive and preparation method thereof

A kind of asphalt mixture, high modulus technology, applied in the direction of building insulation materials, building components, buildings, etc., can solve the problem of weakening the low temperature performance and water stability of asphalt mixture, limiting large-scale promotion and application, compatibility and Poor uniform dispersion and other problems, to achieve the effect of improving convenience, improving low temperature performance and water stability, and improving compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

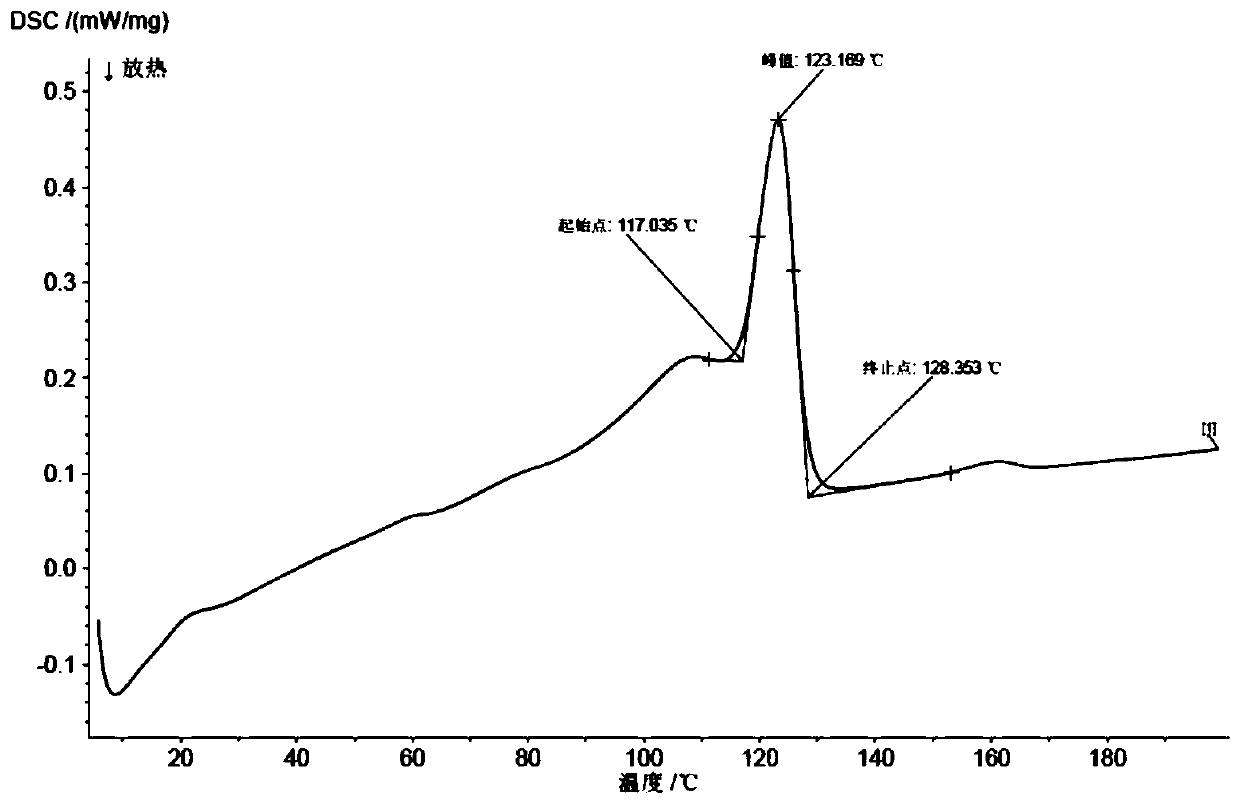

Method used

Image

Examples

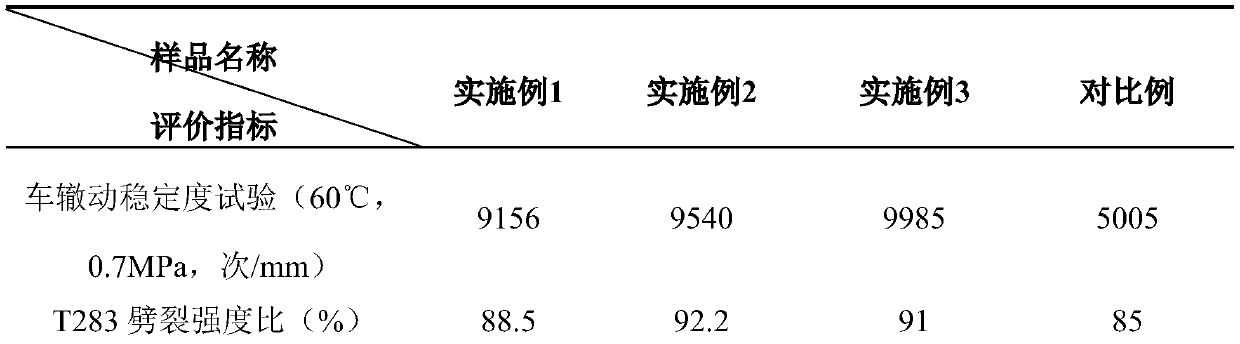

Embodiment 1

[0028] Warm-mix high modulus asphalt mixture additives include the following components by weight, 10 kg of polymer organic wax, 25 kg of thermoplastic elastomer polymer polypropylene, 5 kg of waste truck tire rubber powder (30 mesh), KH~550 5 kg of silane coupling agent, 5 kg of inorganic filler cement, 7 kg of anti-aging agent p-diphenylamine and 40 kg of hard asphalt.

[0029] The preparation process of warm-mix high-modulus asphalt mixture additives is as follows: First, use the auxiliary device of the silo, that is, the electronic metering device to accurately weigh the content of each component, and then control the content of each component in the silo according to the proportion of the components. The feeding speed and the inclination angle of the feed chute, each component is introduced into the feed hopper of the screw extruder through the feed trough, and the mixed components enter the screw extruder through the funnel for mixing, and are extruded by the extruder. A...

Embodiment 2

[0033] The economical high-modulus asphalt mixture additive includes the following components according to the weight, 12 kilograms of high molecular organic wax, 35 kilograms of thermoplastic elastomer polymer low-density polyethylene, 7 kilograms (50 mesh) of waste truck tire rubber powder, titanic acid 5 kg of ester coupling agent, 5 kg of 1:1 mixture of inorganic filler cement and nano-calcium carbonate, 8 kg of anti-aging agent disulfide and 45 kg of natural asphalt.

[0034] The preparation process of economical high modulus asphalt mixture additives is as follows: First, use the auxiliary device of the silo, that is, the electronic metering device to accurately weigh the content of each component, and then control the content of each component in the silo according to the proportion of the components. The material speed and the inclination angle of the feed trough, each component is introduced into the feed hopper of the screw extruder through the feed chute, the mixed c...

Embodiment 3

[0038] The economical high modulus asphalt mixture additive includes the following components according to the weight, 8 kilograms of high molecular organic wax, 45 kilograms of thermoplastic elastomer polymer polystyrene, 5 kilograms (40 mesh) of waste car tire rubber powder, aluminate 5 kg of coupling agent, 5 kg of inorganic filler cement and nano calcium carbonate 2:1 mixture, 9 kg of anti-aging agent diphenylamine and 50 kg of hard asphalt.

[0039] The preparation process of economical high modulus asphalt mixture additives is as follows: First, use the auxiliary device of the silo, that is, the electronic metering device to accurately weigh the content of each component, and then control the content of each component in the silo according to the proportion of the components. The material speed and the inclination angle of the feed trough, each component is introduced into the feed hopper of the screw extruder through the feed chute, the mixed components enter the screw e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com