Method for compensating and regulating heating temperature of centralized heat supply network

An adjustment method and temperature compensation technology, applied in space heating and ventilation details, household heating, heating methods, etc., can solve the problems of reducing emissions and saving fuel, and achieve the goals of reducing emissions, saving fuel, and being easy to operate and realize Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

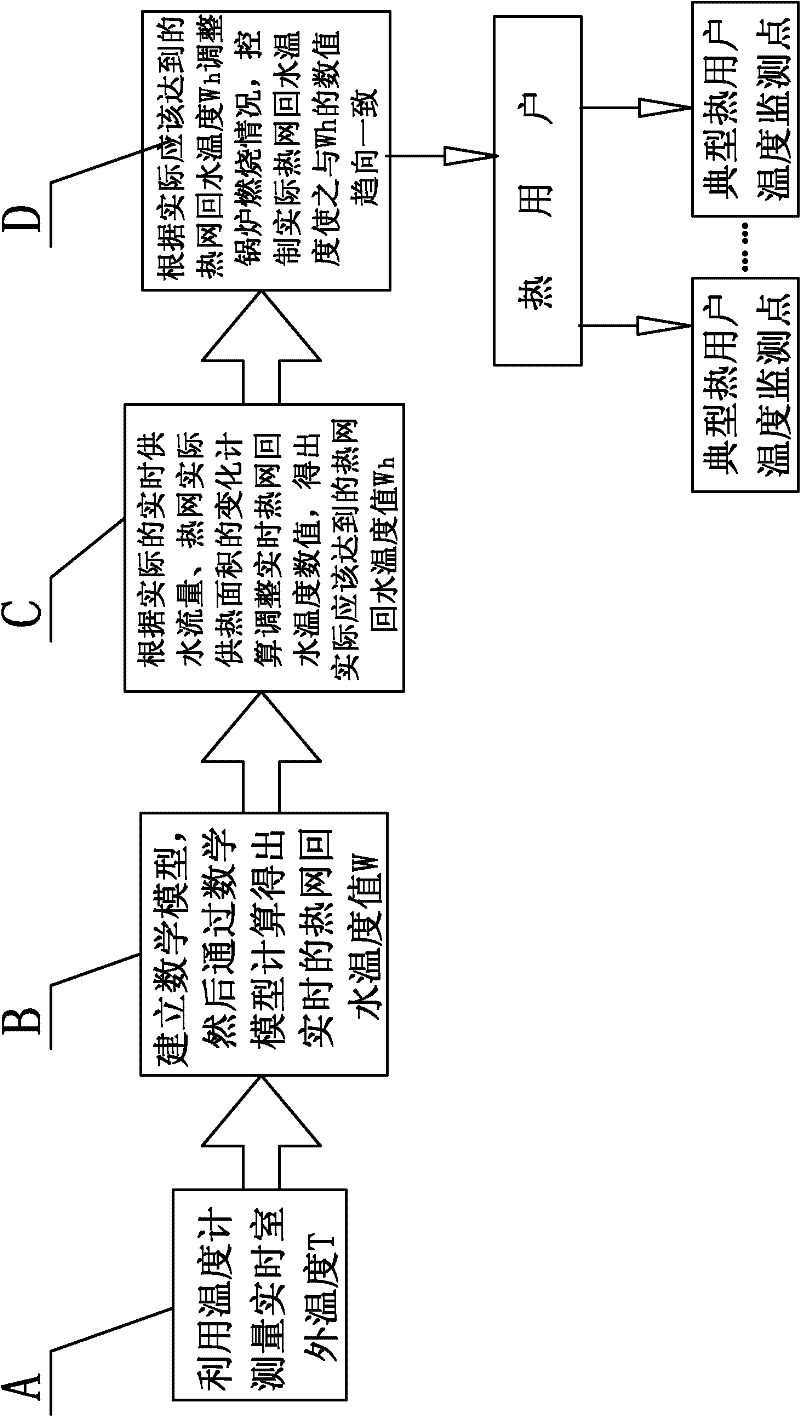

[0033] Specific implementation mode one: as figure 1 As shown, the specific process of a heating temperature compensation adjustment method for a central heating network described in this embodiment is:

[0034] Step A, using a thermometer to measure the real-time outdoor temperature T;

[0035] Step B, establish a mathematical model, and then calculate the real-time return water temperature value W of the heating network through the mathematical model. The specific process is:

[0036] Step B1, when the outdoor temperature T is 0°C, W=38.5°C;

[0037] Step B2, when the outdoor temperature T>0°C, W=38.5-0.65×|W1|;

[0038] Step B3, when the outdoor temperature T<0°C and ≥-20°C, W=38.5+K1×|W1|;

[0039] Step B4. When the outdoor temperature T<-20°C,

[0040] W=38.5+K1×20+K2×(|W1|-20);

[0041] In the formula:

[0042] W represents the return water temperature value of the heating network calculated according to the outdoor air temperature, in °C;

[0043] |W1| indicates ...

specific Embodiment approach 2

[0054] Specific implementation mode two: In this implementation mode, in step D, control the return water temperature W of the heating network h1 and the actual return water temperature of the heating network that should be achieved W h The absolute value of the difference between the two is less than or equal to 0.5°C. Other steps are the same as in the first embodiment.

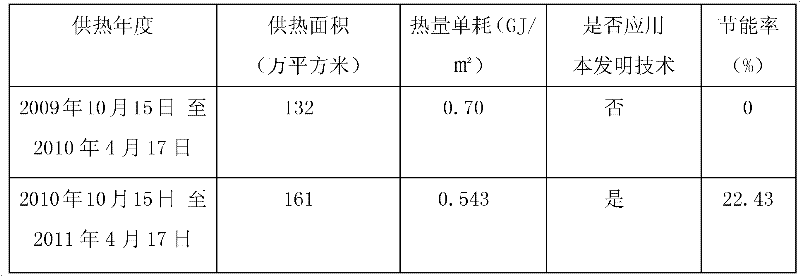

[0055] The hardware needed to realize the method of the present invention includes a thermometer, a temperature signal transmitter, an outdoor shutter box, a transmission cable, a DCS system for controlling boiler combustion, and the like. According to the difference of the computer languages used in the DCS system for controlling boiler combustion, the method of the present invention is programmed and written into the computer of the DCS system. Measure the outdoor temperature T through a thermometer, and then convert the temperature signal into an electrical signal through a temperature signal transmi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com