Method and device for utilizing heat energy of flue gas produced by calcining in rotary kiln in process of producing titanium dioxide by sulfuric acid method

A technology of rotary calcination kiln and titanium dioxide, which is applied in the direction of rotary drum furnace, waste heat treatment, and energy efficiency improvement. It can solve the problems of no high-temperature flue gas purification, waste of resources and energy, and affect product quality, so as to improve product yield. , the effect of energy saving and emission reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

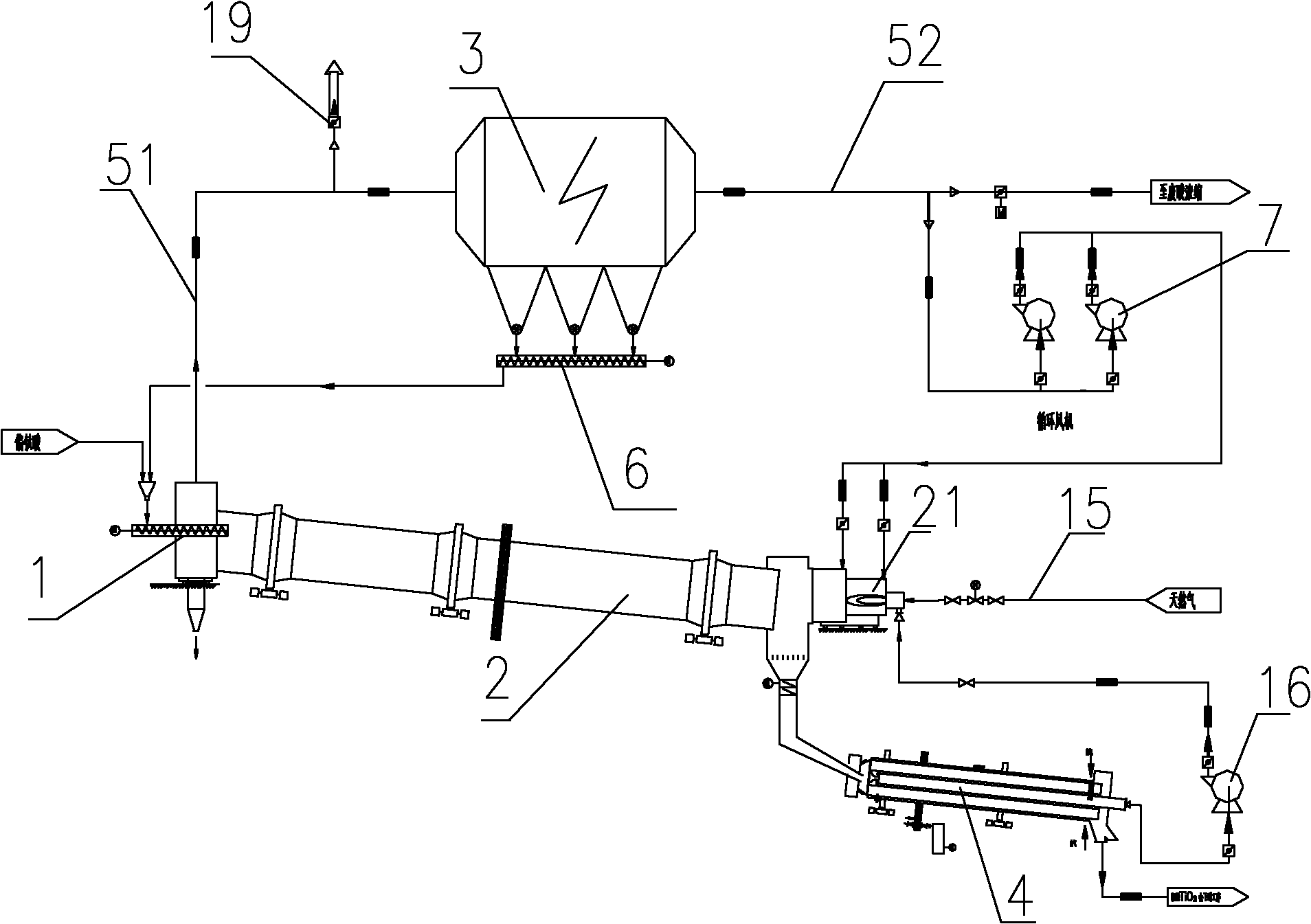

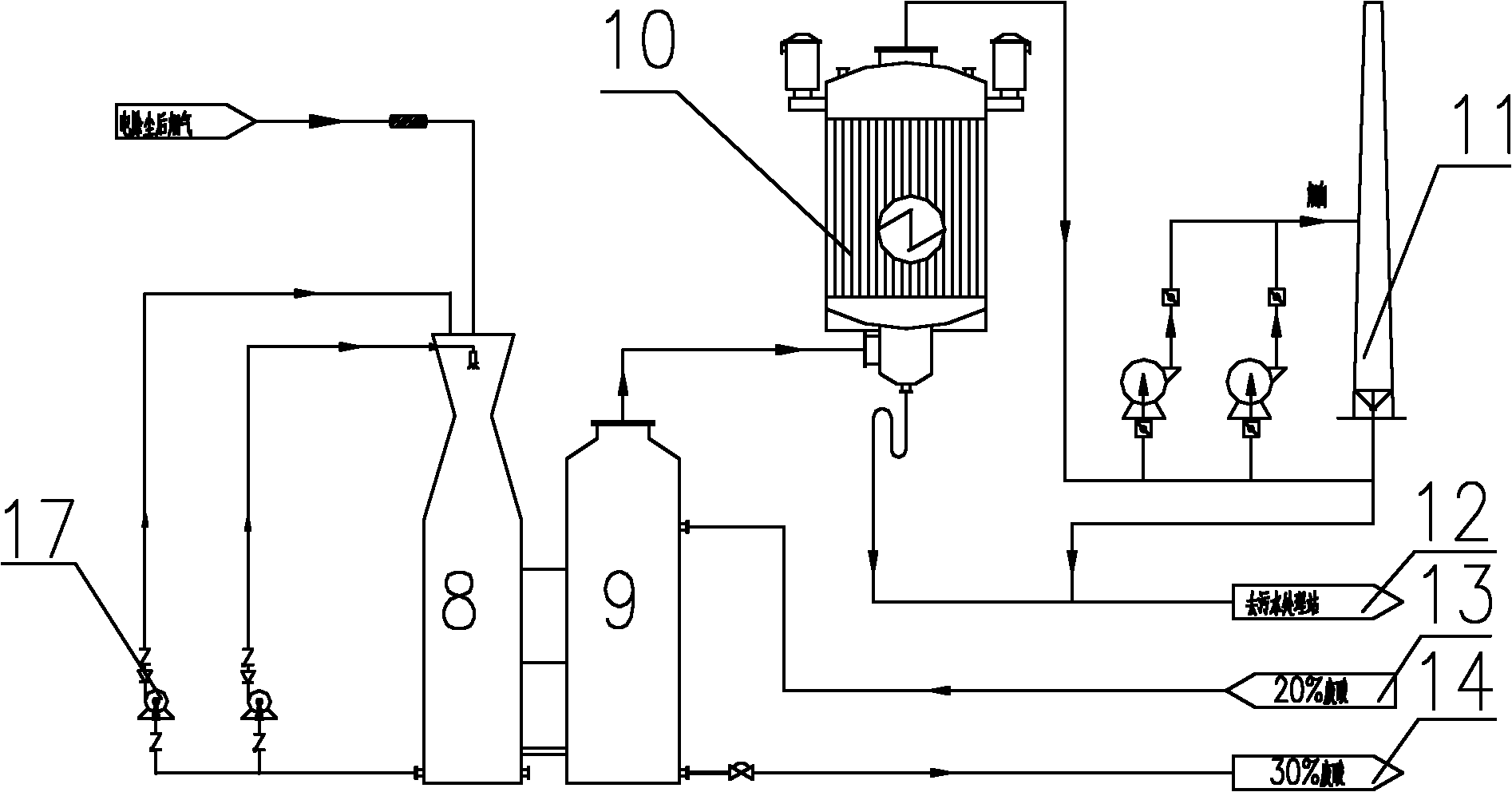

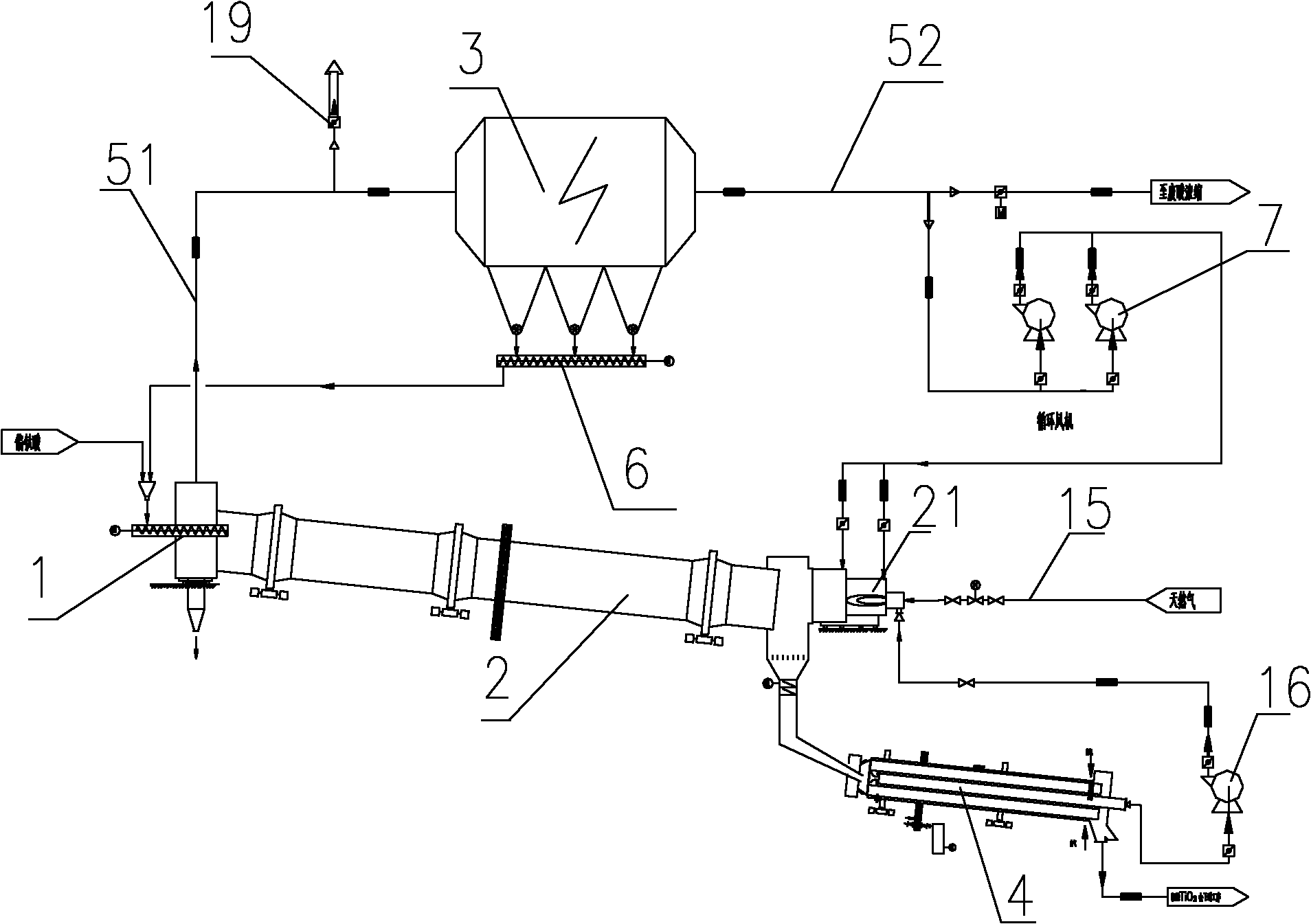

[0018] The implementation of the present invention will be described in detail below in conjunction with the accompanying drawings, but they do not constitute a limitation to the present invention, and are only examples. At the same time, the advantages of the present invention will become clearer and easier to understand.

[0019] The basic principle of the present invention is: metatitanic acid is hydrated titanium dioxide (TiO 2 · xSO 3 ·yH 2 O), wherein the solid content of titanium dioxide is usually 54-56%, and most of the others are water. When metatitanic acid is calcined in a rotary kiln, it undergoes dehydration, desulfurization, particle growth and crystal transformation to produce titanium dioxide with pigment properties. Chemical reaction formula:

[0020] TiO 2 · xSO 3 ·yH 2 O→TiO 2 +xSO 3 ↑+yH 2 O↑

[0021] The maximum temperature of metatitanic acid calcination reaches 960-980°C, and the discharged high-temperature flue gas has a large volume and hig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com