Low-temperature exhaust air source spray heat capturing efficient water source heat pump fresh air system

A water source heat pump and fresh air system technology, which is applied in heat pumps, lighting and heating equipment, refrigeration components, etc., can solve the problems of heat pump heating and heating energy efficiency attenuation, evaporation temperature reduction, heat pump heat absorption and heating energy efficiency attenuation and other problems , to achieve the effect of improving heating and heating energy efficiency, improving operating efficiency, reducing initial investment and operating power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

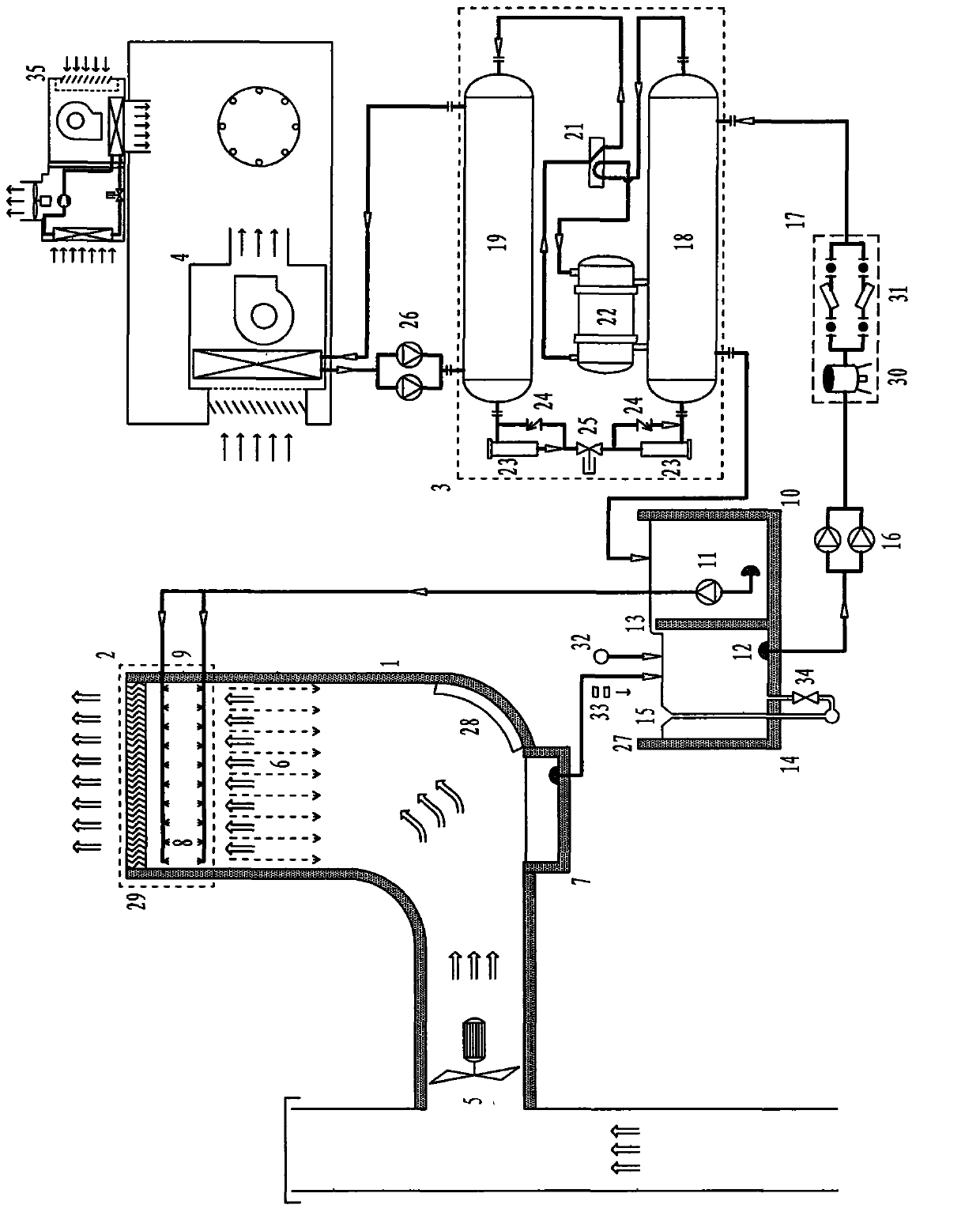

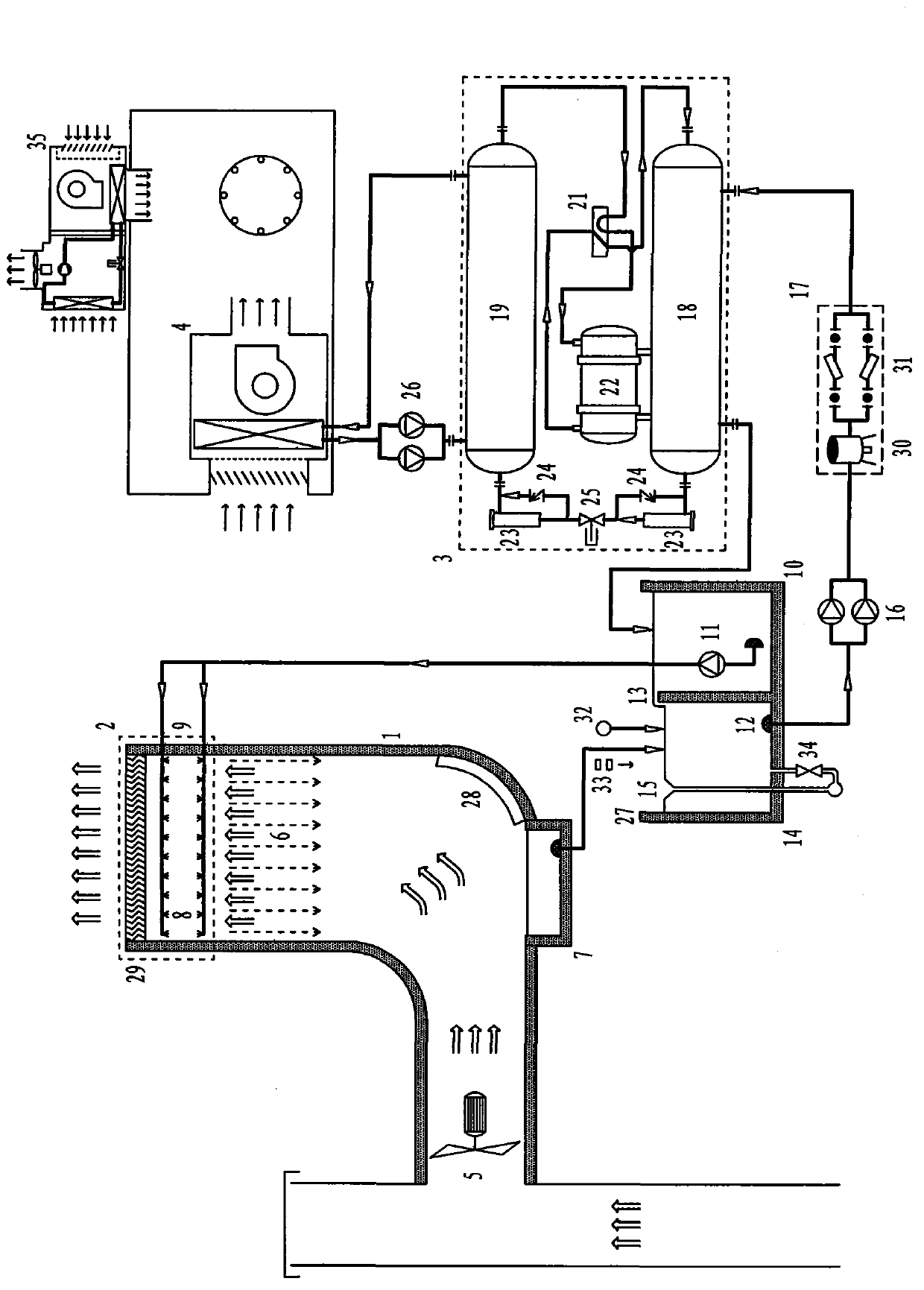

[0049] The embodiment of the high-efficiency water source heat pump fresh air system proposed by the present invention is attached by spraying the low-temperature exhaust air source figure 1 As shown, the description is as follows: a circular exhaust source with a height of 20m and an outlet diameter of 6m leads to a standpipe, and is connected to a downward curved exhaust source diffusion tower 1 with a length of 10m×width of 6.7m through a curved air duct; the length is 10m ×Width 6.7m×Height 1.4m antifreeze spray room 2; 4 sets of heating capacity 787kW, power 185kW, antifreeze inlet temperature 1°C / outlet temperature -2°C, antifreeze flow rate 203m 3 / h, water supply temperature on the use side 35°C / return water temperature 27°C, circulating water flow 85m 3 / h high-flow heat-absorbing high-efficiency water source heat pump 3; 6 units with a rated air volume of 1167m 3 / m, 4 fresh air air conditioning boxes with inlet water temperature 35°C / outlet water temperature 27°C c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com