Self-heating continuous carbonization and activation processing method for biomass and device thereof

A processing method and biomass technology, applied in chemical instruments and methods, sustainable manufacturing/processing, chemical industry, etc., to achieve good environmental protection effects and save energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

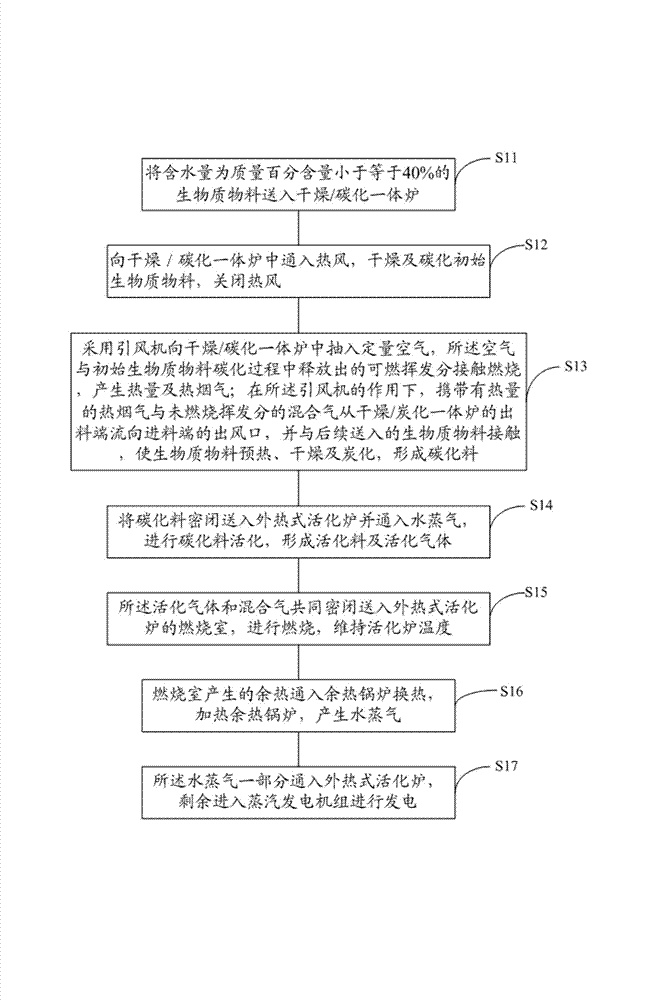

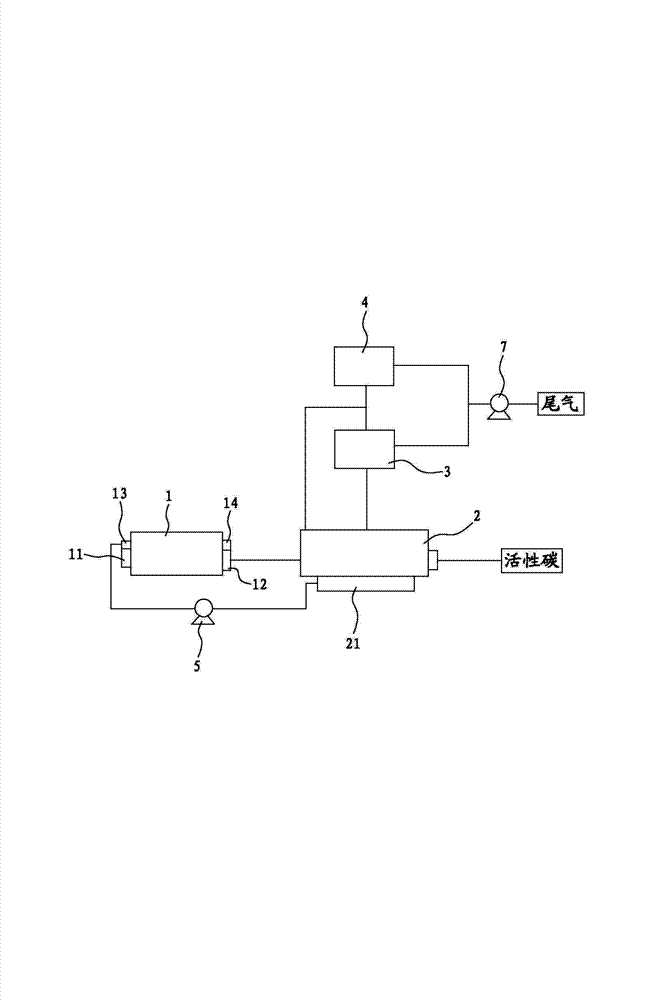

[0023] In order to solve the problems existing in the existing process and equipment, the inventor of the present invention proposes a technical solution, the specific process is as follows: figure 1 Shown: Step S11: Send biomass material with a water content of 40% or less by mass into the drying / carbonization integrated furnace; Step S12: Pass hot air into the drying / carbonization integrated furnace to dry and carbonize the initial biomass Material, turn off the hot air; step S13: use the induced draft fan to draw a certain amount of air into the drying / carbonization integrated furnace, and the air will contact and burn with the flammable volatile matter released during the carbonization process of the initial biomass material to generate heat and hot flue gas; Under the action of the induced draft fan, the mixture of hot flue...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com