Preparation method for co-modified copper bismuthate nanorod photocathodes

A photocathode and nanorod technology, which is applied in the manufacture of light-emitting cathodes, nanotechnology, nanotechnology, etc., can solve problems such as incomparability, and achieve good photocatalytic activity, visible light response characteristics, and improved stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

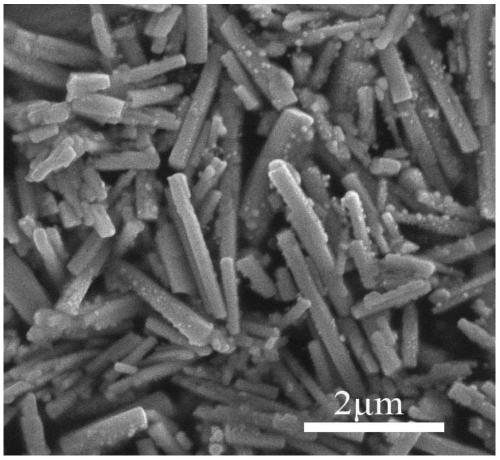

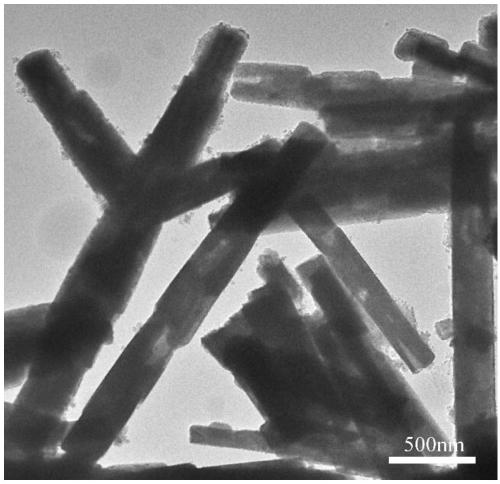

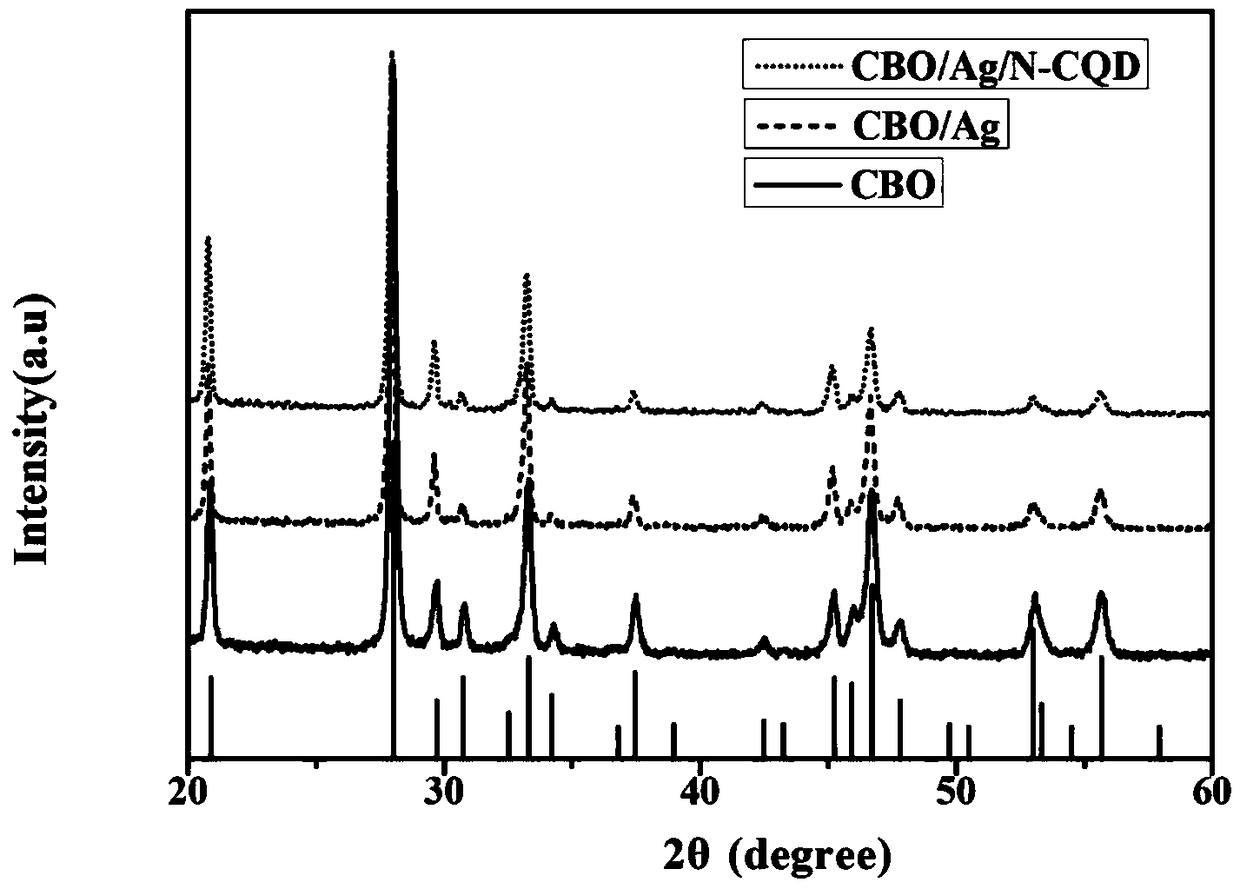

[0034] This embodiment provides a method for preparing a co-modified copper bismuthate nanorod photocathode, comprising the following steps:

[0035] Step S1, 2.42g Bi(NO 3 ) 3 ·5H 2 O, 0.6g Cu(NO 3 ) 3 ·5H 2 O and 0.87g NaOH were added to 40mL deionized water successively, stirred for 3 hours and dissolved to obtain a solution;

[0036] Step S2, transfer the solution obtained in step S1 to a polytetrafluoroethylene-lined autoclave, and react at 180°C for 24 hours. After the reaction, the autoclave is cooled to room temperature, and the solid product in the solution is centrifuged , washed alternately with absolute ethanol and high-purity water three times each, and then dried in a drying oven at 60°C to obtain CuBi 2 o 4 Nano stave;

[0037] Step S3, weighing 30mg of CuBi prepared in step S2 2 o 4 Nanorods were added to 10 mL of absolute ethanol, followed by different volumes of 0.05M AgNO 3 solution, stirred for 3 hours to adsorption equilibrium, and dried in a dr...

Embodiment 2

[0055] In this embodiment, nitrogen-doped carbon quantum dots prepared in Example 1 and silver co-modify CuBi 2 o 4 The nanorod photocathode was tested for photocatalytic performance, and the test conditions were as follows: a standard three-electrode system was used, and a saturated calomel electrode and a Pt wire electrode were used as the reference electrode and the counter electrode, respectively. AM 1.5 solar simulator (100mW / cm 2 ) as the lighting source. Take 85mL of 0.5ML phosphate buffer solution in the photoelectric reaction cell, the distance between the light source and the reaction system is 10cm, and the irradiation distance from the front is 0.5cm 2 of the electrolyte exposed area of the working electrode. The potential range is -0.6-0.5V, and the scanning speed is 10mV˙s -1 . Electrode potential adopts RHE standard, E (RHE) =E (SCE) +0.059*6.6+0.242.

[0056] From Figure 8 Analysis of the photoelectric performance graph results shown, compared with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com