Blast furnace slag gas quenching microsphere waste heat recovery device

A technology of waste heat recovery device and waste heat recovery system, which is applied in steam engine devices, recycling technology, furnaces, etc., can solve the problems of large loss of heat energy grade, large water consumption, and difficult to deal with harmful gases, and achieve obvious energy saving and emission reduction. Economic value, the effect of convenient transformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

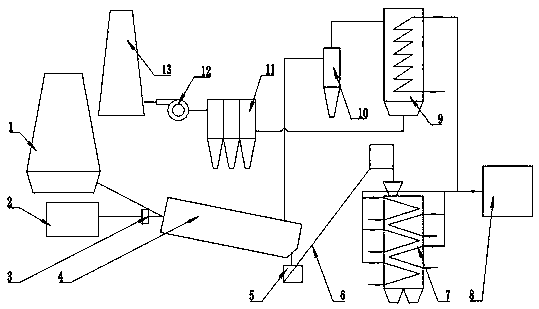

[0021] Example 1: A blast furnace slag gas-quenching microsphere waste heat recovery device, including a gas-quenching granulation system and a waste heat recovery system; the gas-quenching granulation system includes a blast furnace 1, a high-temperature liquid high A gas quenching device 3 for quenching slag into microbeads, a rotary slag solidifier 4 connected to the blast furnace 1 and the gas quenching device 3 for forming and cooling the microbeads, and the waste heat recovery system includes solid-liquid waste heat Boiler 7 and gas-liquid waste heat boiler 9; the top end of the tail of the rotary slag coagulator 4 is connected to the gas-liquid waste heat boiler 9 through a multi-tube dust collector 10, and the bottom of the gas-liquid waste heat boiler 9 is passed through a bag filter 11 and an induced draft fan 12 is connected with the chimney 13, and the hot air generated during the granulation process is purified by the multi-tube dust collector 10 from the tail end ...

Embodiment 2

[0022] Embodiment 2: Further improvement on the basis of Embodiment 1, the gas quenching device 3 includes an air compressor 2, a nozzle, a pipeline pressure regulating valve, an electric control valve, a start regulating valve, a flow meter, a pressure gauge, a high pressure Gas pipes, metal hoses, and flow meters; the nozzles described are Laval nozzles, which can blow high-temperature liquid blast furnace slag gas into microbeads with a particle size of 2 mm; the Mach number of the nozzles is 1.6.

Embodiment 3

[0023] Embodiment 3: Further improvement on the basis of Embodiment 1 or 2, the rotary slag coagulator 4 is lined with heat-insulating and wear-resistant materials, a 1.5m slag-wool separation device is installed at the rear, and a slag is installed in the tail smoke hood. Granular buffer silo.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com