Process for hydrocracking of Fischer-Tropsch synthesized heavy hydrocarbon and/or kettle bottom wax

A Fischer-Tropsch synthesis and hydroconversion technology, which can be used in the treatment of moving solid particles, etc., can solve the problems of boiling point, high olefin and solid content, technical difficulties, etc., and achieve the effects of mild reaction conditions, flexible operation and easy availability of sources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

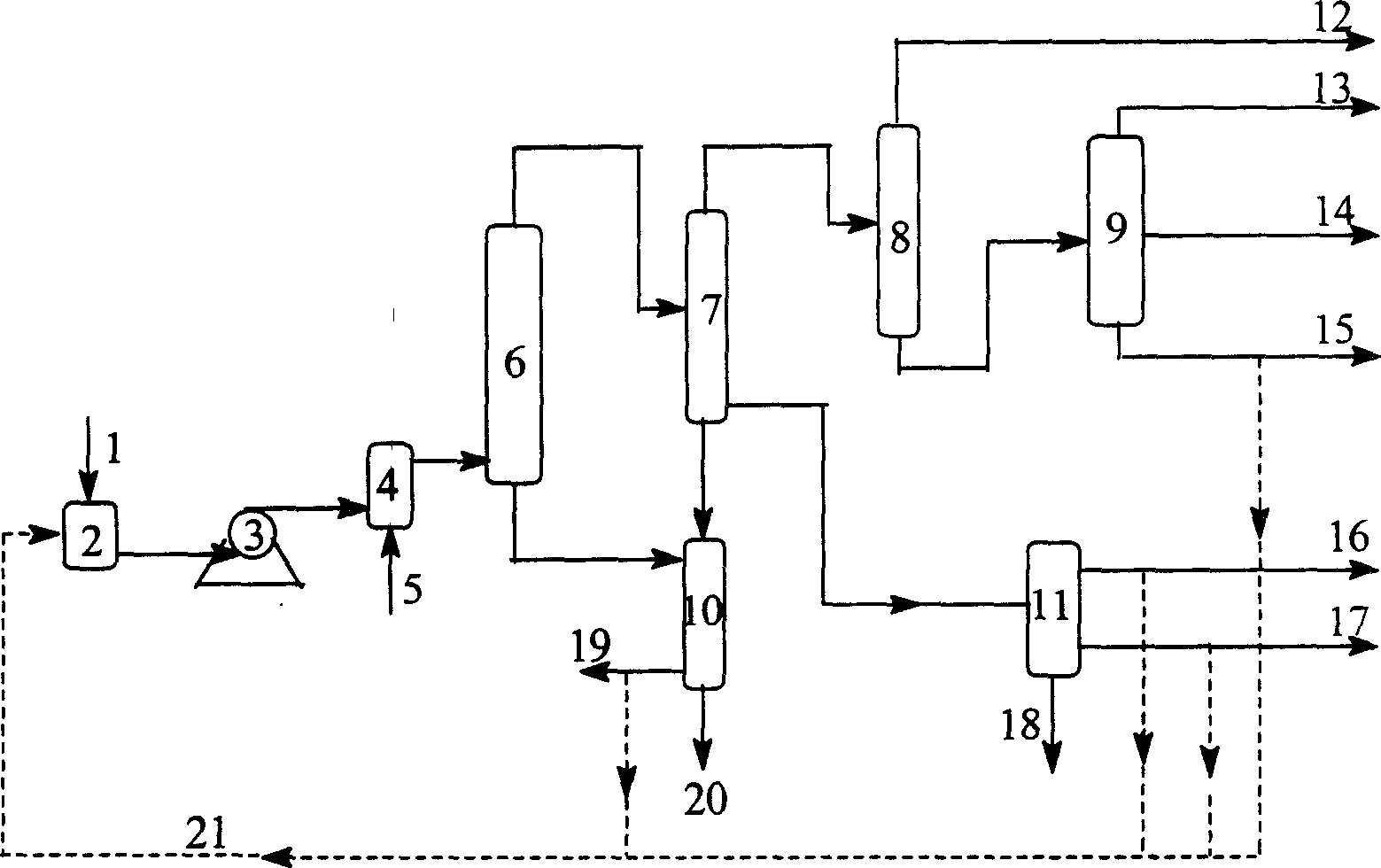

[0023] Fig. 1 is a flow chart of the present invention.

[0024] As shown in the figure: 1 is the feed pipeline 2 is the oil storage tank 3 is the metering pump 4 is the preheating tank 5 is the hydrogen 6 is the suspension bed reactor 7 is the hot high separation system 8 is the cold high separation system 9 is the normal pressure separation Tower 10 is cyclone separator 11 is vacuum distillation tower 12 is tail gas 13 is naphtha 14 is diesel fraction 15 is light wax oil 16 is heavy wax oil 17 is tail oil 18 is residue 19 is tail oil 20 is residue 21 It is a circulating cracking pipeline.

[0025] Mix the Fe-based water-soluble catalyst and raw materials evenly in the oil storage tank 2, then mix and heat with hydrogen in the preheating tank 4 and enter the suspension bed reactor 6 for hydrogenation conversion; or pre-pack the iron-based waste catalyst in the suspension bed reaction In the reactor 6, the raw material and hydrogen are mixed and heated in the preheating tank ...

Embodiment 1

[0028] The active proportion of the suspended bed water-soluble catalyst is Fe:Mn:Co:Ni=80:10:7:3, the total metal content is 10.5wt%, and the raw material is heavy hydrocarbon synthesized by iron-based slurry bed Fischer-Tropsch, with a boiling point greater than 530°C.

[0029] First, the catalyst and the heavy hydrocarbon feedstock are mixed evenly in the oil storage tank 2, based on the Fischer-Tropsch synthesis of heavy hydrocarbons, calculated as metals, the amount of catalyst added is 500 μg / g; then mixed with hydrogen in the preheating tank 4 and heated to 400°C Then enter the suspended bed reactor 6, at a reaction pressure of 6.0MPa, a reaction temperature of 410°C, a hydrogen-to-oil volume ratio (under standard pressure) of 800, and a liquid space velocity of 0.3h -1 Under the conditions of hydrogenation conversion. The reacted product flows out from the top of the suspended bed reactor 6 and enters the thermal high separation system 7 for separation. The gas phase...

Embodiment 2~5

[0031] The method of embodiment 2~5 is the same as embodiment 1, but catalyst and reaction condition are changed to some extent, operating condition and experimental result are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com