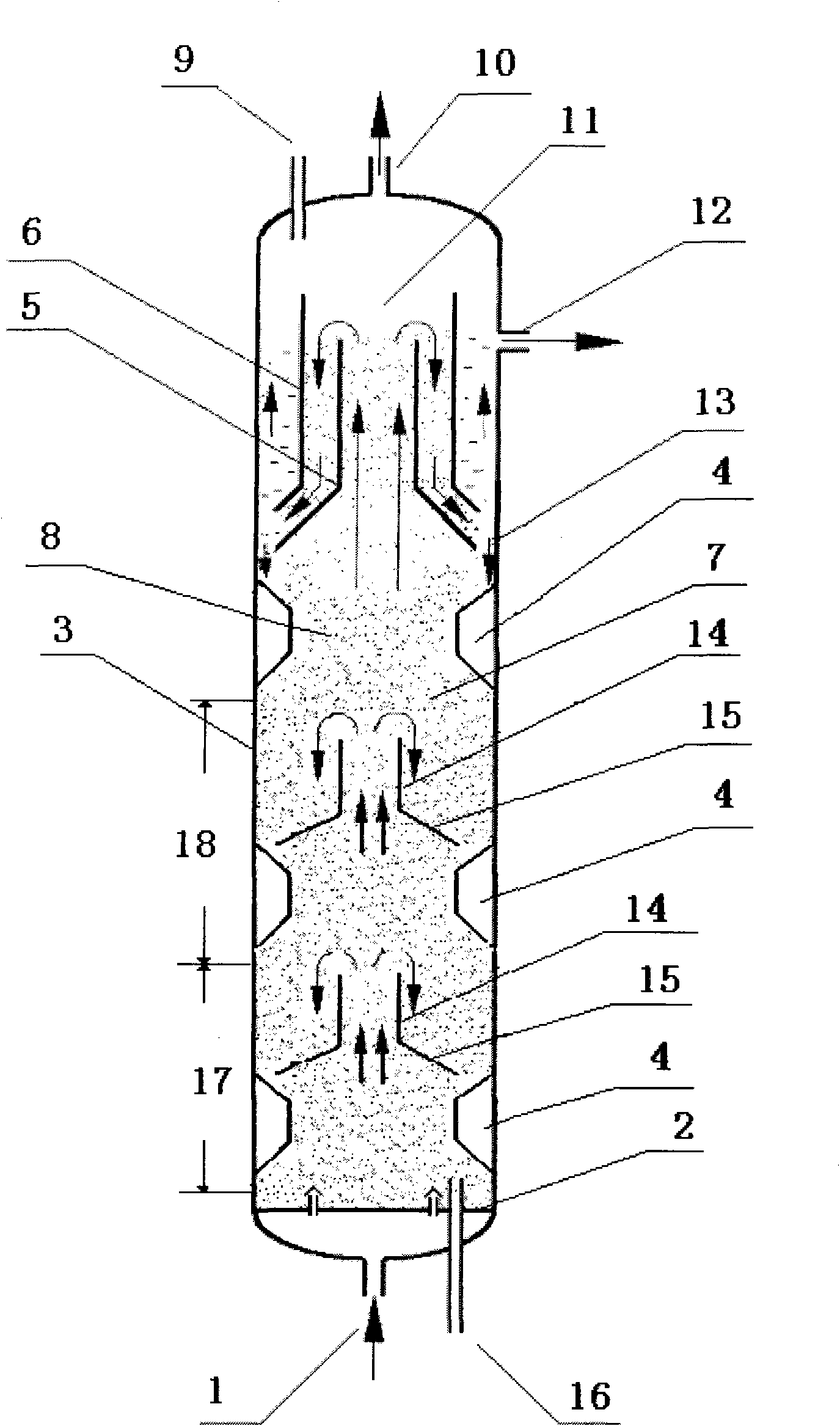

Catalyst-graded fluidized bed hydrogenation process

A fluidized bed and catalyst technology, which is applied in the petroleum industry, hydrocarbon oil cracking, and treatment with moving solid particles, can solve the problems of limiting catalyst expansion ratio, wasting reaction volume, increasing operation difficulty, etc., and achieves strong adaptability of raw materials and high utilization The effect of small amount and large porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

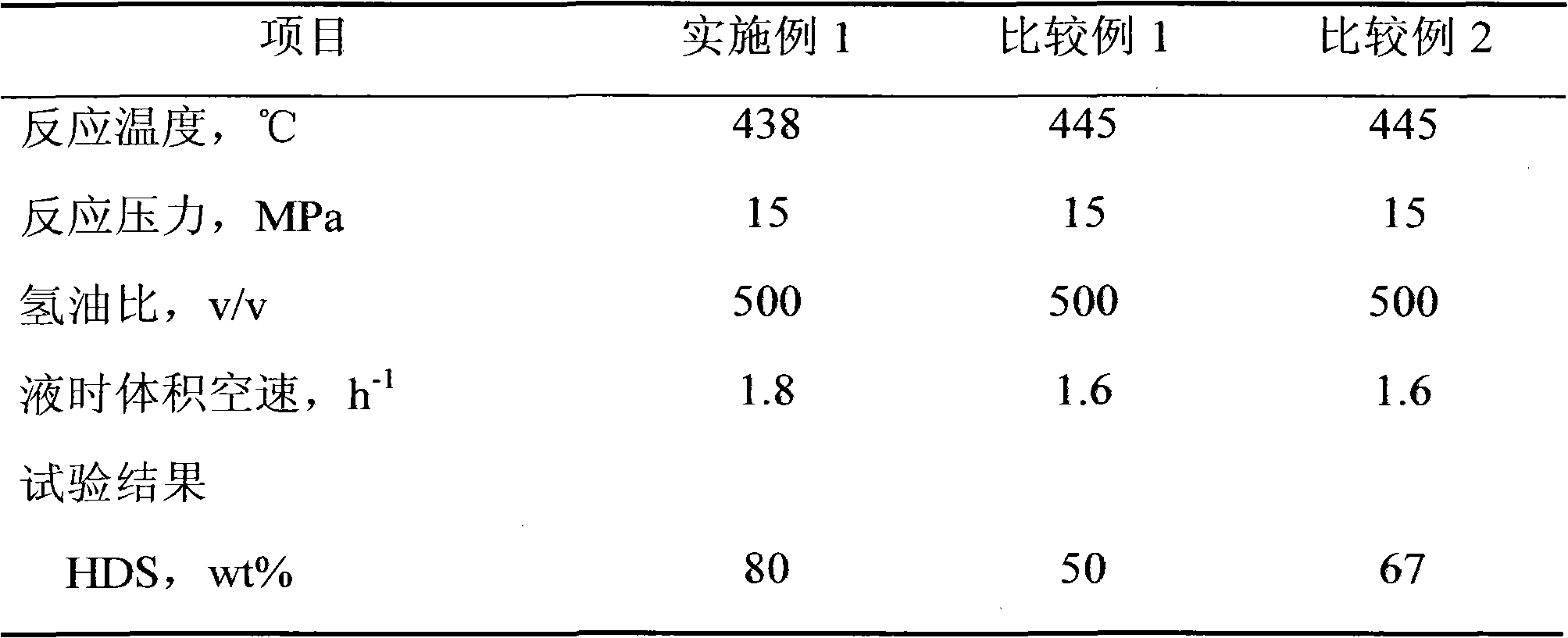

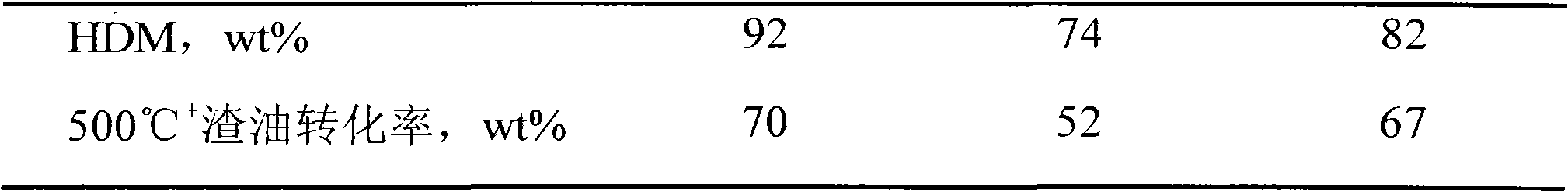

[0030] This example is an embodiment of using an ebullating bed hydrogenation reactor with two internal circulations to process inferior oil. Wherein the catalysts with different hydrogenation activities are respectively used in the two internal circulation areas, and the nature and composition of the catalysts used in the internal circulation area 17 near the bottom of the reactor are: nickel 1% (calculated by its oxide), tungsten is 4% ( Calculated according to its oxide), the bulk density is 0.7g / cm 3 , the particle diameter is 0.6mm, and the specific surface area is 90m 2 / g; The nature and composition of the catalyst used near the reactor top internal circulation zone 18 are: nickel 3% (calculated by its oxide), molybdenum 10% (calculated by its oxide), and the bulk density is 0.54g / cm 3 , the particle diameter is 0.3mm, and the specific surface area is 220m 2 / g. The catalyst loading ratio of the internal circulation zone 17 and the circulation zone 18 is 3:1.

[003...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com