Process for hydroconversion of petroleum feedstocks via a slurry technology allowing the recovery of metals from the catalyst and from the feedstock using a coking step

a petroleum feedstock and hydroconversion technology, which is applied in the direction of catalyst activation/preparation, metal/metal-oxide/metal-hydroxide catalyst, physical/chemical process catalyst, etc., can solve the problem of metals being recovered much more complex than those of refining catalysts supported by supporting forces, and achieve good metal recovery levels, minimize residual fraction, and improve the effect of hydroconversion known processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

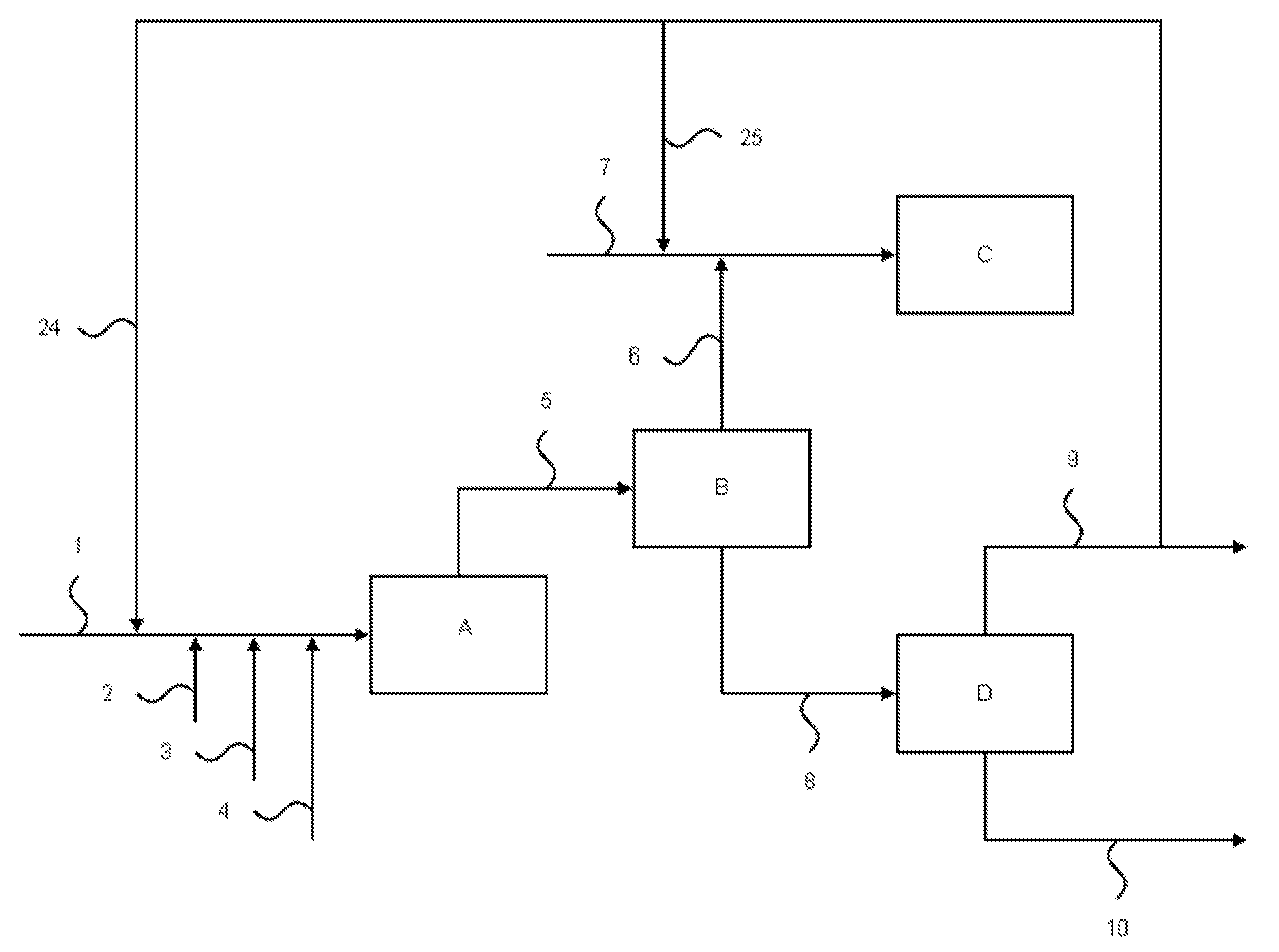

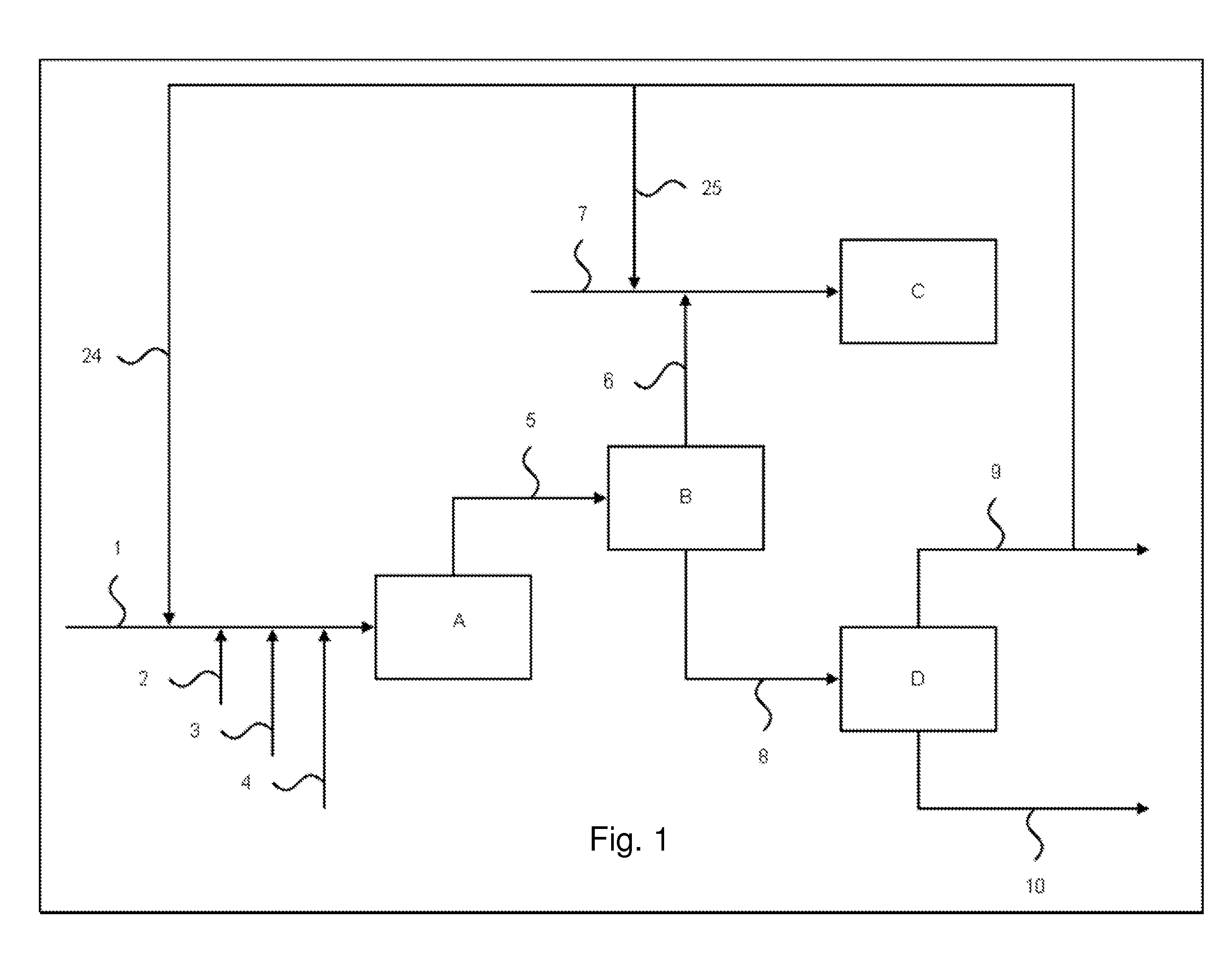

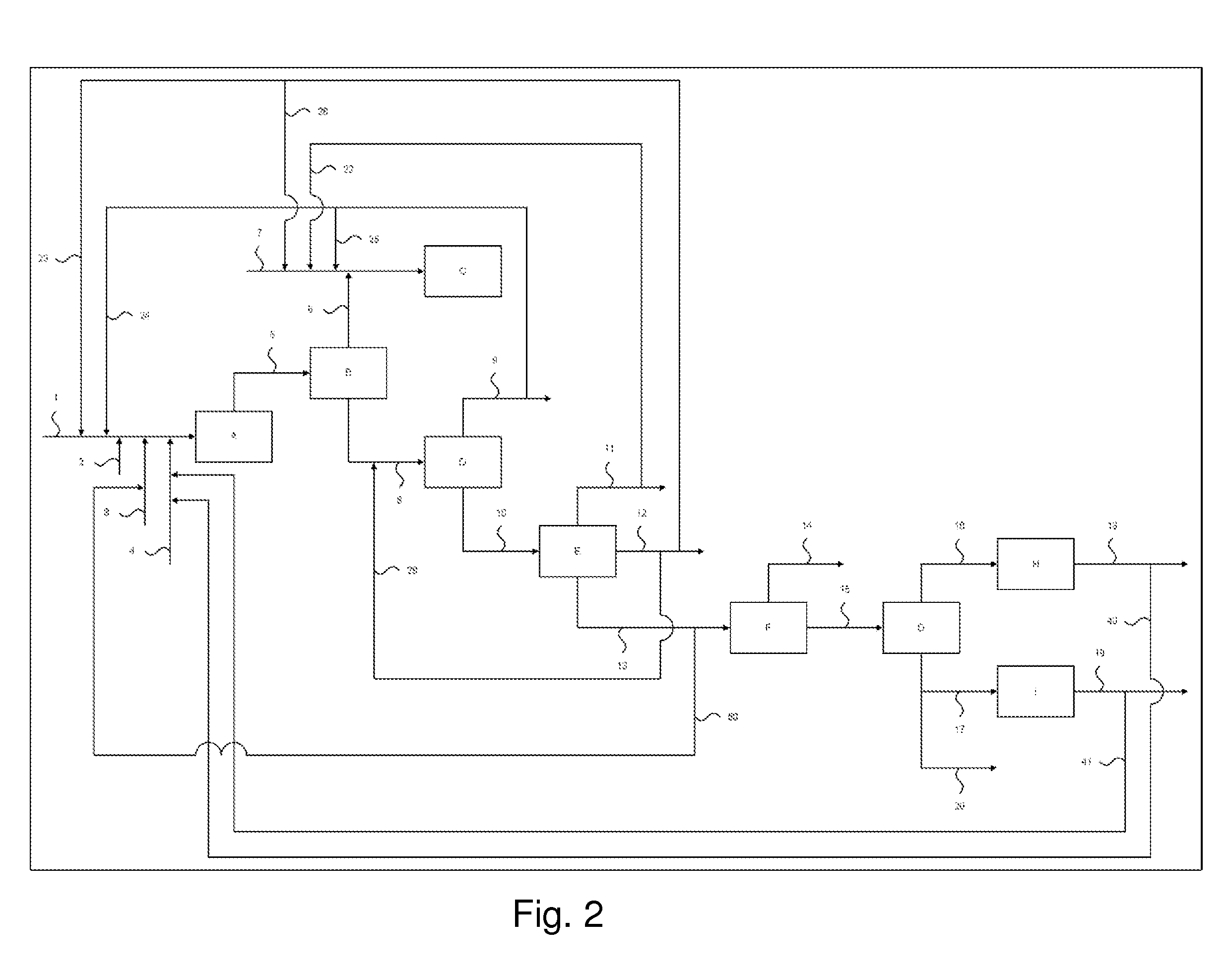

[0025]The invention relates to a process for hydroconversion of heavy petroleum feedstocks in slurry allowing the recovery and recycling of the metals in the unconverted residual fraction, in particular those used as catalysts.

[0026]More particularly, the invention relates to a process for hydroconversion of heavy petroleum feedstocks containing metals comprising:

[0027]a) a step of hydroconversion of the feedstock in at least one reactor containing a slurry catalyst containing at least one metal, and optionally containing a solid additive,

[0028]b) a step of separation of the hydroconversion effluent without decompression into a so-called light fraction containing the compounds boiling at a maximum temperature of 500° C. and a residual fraction,

[0029]b′) optionally a fractionation step comprising a separation under vacuum of said residual fraction as obtained in step b), and a vacuum residue with a high concentration of metals is obtained,

[0030]c) a step of coking of said residual fr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com