Highly active slurry catalyst composition

a slurry catalyst, high-active technology, applied in the direction of catalyst activation/preparation, organic compound/hydride/coordination complex catalyst, physical/chemical process catalyst, etc., can solve the problem that the patent does not demonstrate the criticality of oil viscosity, and the significance of maintaining, etc., to achieve the effect of high-viscosity carbonaceous

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Catalyst Preparation

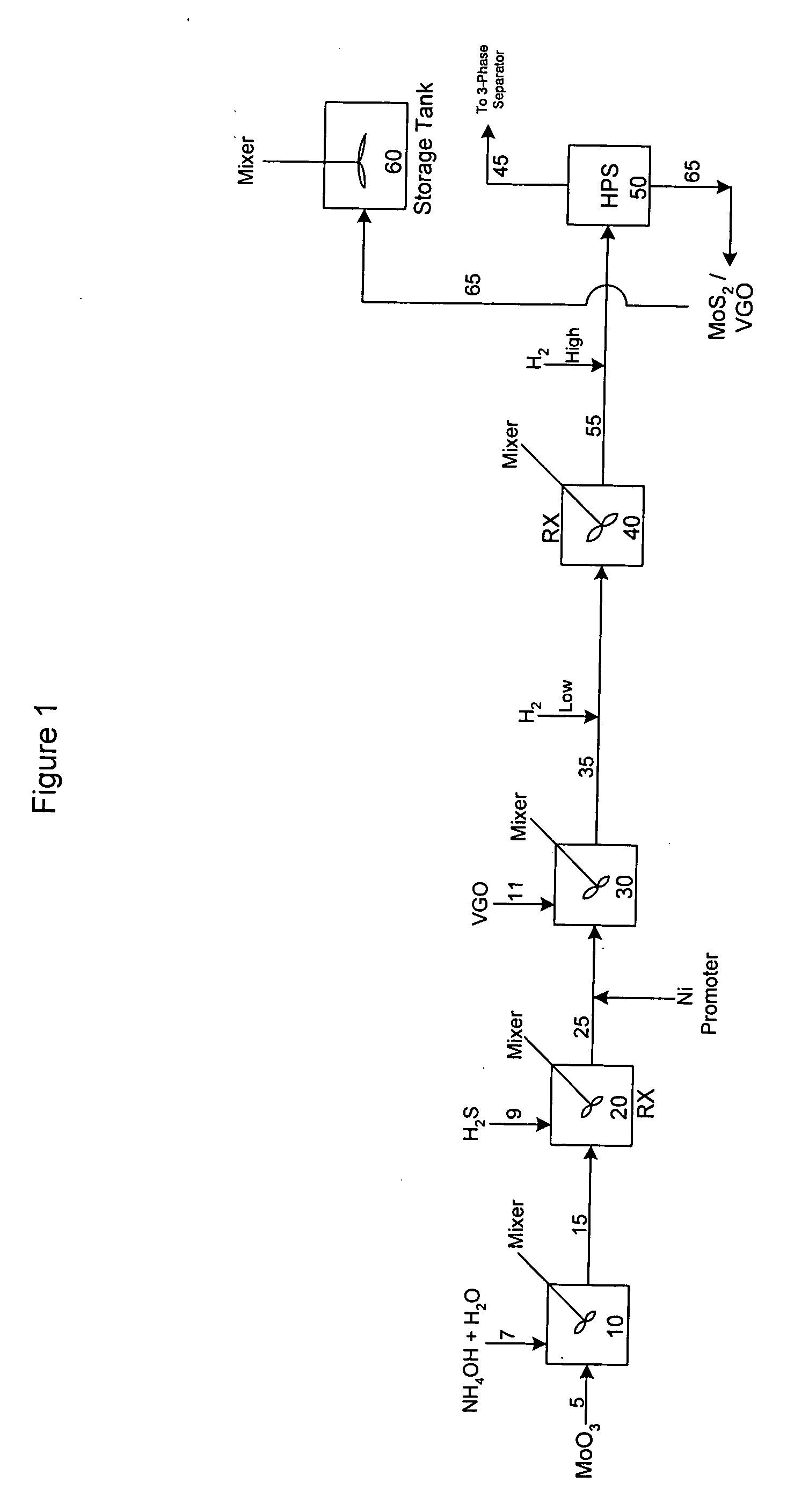

[0027] 540 gram MoO3 is mixed with 79 gram of NH3 and 2381 gram of H2O to form a solution of total 3000 gram. The solution is then reacted with 10.71 SCF of H2S by passing a gas mixture of 20% H2S in H2 into the solution under strong mixing. The reactor temperature is 150° F. and the total pressure is 400 psig, and the reaction time is 4 hours. After reaction, 460 gram NiSO4 solution which contains 36 gram of Ni is added to the above obtained slurry. The obtained slurry mixture is then mixed with 8000 gram of vacuum gas oil at 100° F. The viscosity of the VGO is 5 cSt @ 212° F. The resulting mixture is then pumped into a continuously flow tanked reactor (perfectly mixed flow reactor) with H2. The H2 gas rate is 300 SCF / B. The reactor pressure is 400 psig and reactor temperature is 400° F., the total reaction time is 1 hour. The reaction products are mixed with more H2 at a gas rate of 1500 SCF / B and then go to a hot high pressure separator, which is also maintai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com