Hydrotreated hydrocarbon tar, fuel oil composition, and process for making

a technology of hydrocarbon tar and hydrocarbon slag, which is applied in the direction of tar working up by chemical refining, thermal non-catalytic cracking, fuels, etc., can solve the problems of poor combustion quality, insoluble slag in steam cracker tar, and insoluble slag in many low-sulfur fuel oil formulations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0044]Steam cracker tar at 1.1 g / cc and 2.2 wt % sulfur (S) was hydrotreated at 1000 psig (pounds per square inch gauge), 400° C., and 0.4 LHSV (liquid hourly headspace velocity) with 1400 SCFB (standard cubic feet per barrel) hydrogen cofeed. Hydrogen consumption was 1200 SCFB of feed, resulting in a composition with a density of 1.02 g / cc and 0.4 wt % S.

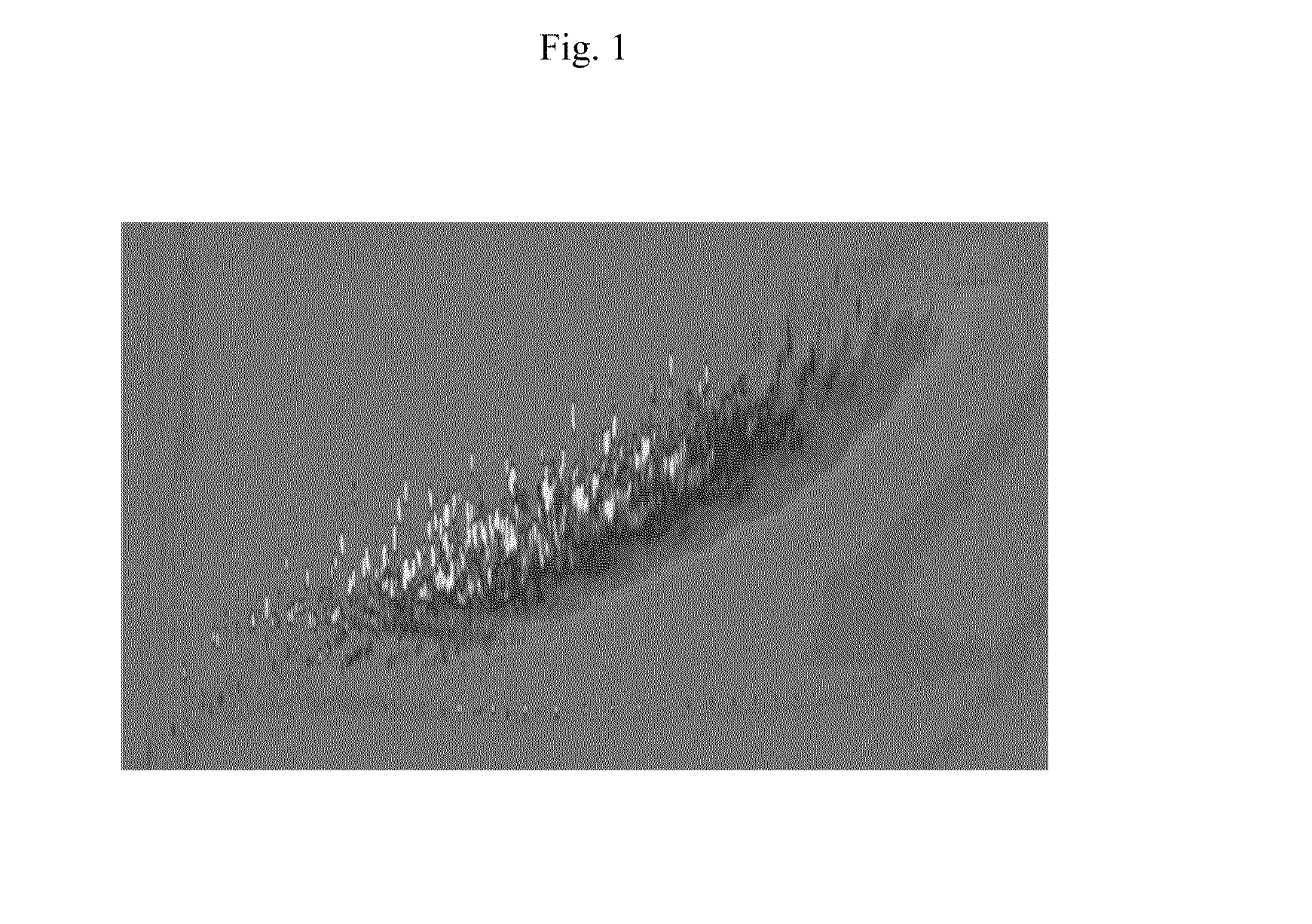

[0045]The resulting hydrotreated composition is a suitable as a fuel oil blending component. A 2D GC image of the composition is set forth in FIG. 1. In FIG. 1, the peaks for the aromatics increase in carbon number along the slope, with the peak for C20 situated generally in the middle along the slope. The generally linear line of peaks along the bottom of the image represent paraffin waxes, which make up 25-29 fraction of the hydrotreated composition. The C25-29 fraction was obtained via distillation in a spinning band distillation column.

[0046]The 500+ component hydroprocessed steam cracker tar of the present example is useful as...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| wt % | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com