Preparation method and catalytic application of supported type high-dispersion nickel-based alloy catalyst

A nickel-based alloy, highly dispersed technology, applied in the direction of metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve problems such as poor stability, improve conversion rate, Improved selectivity and ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

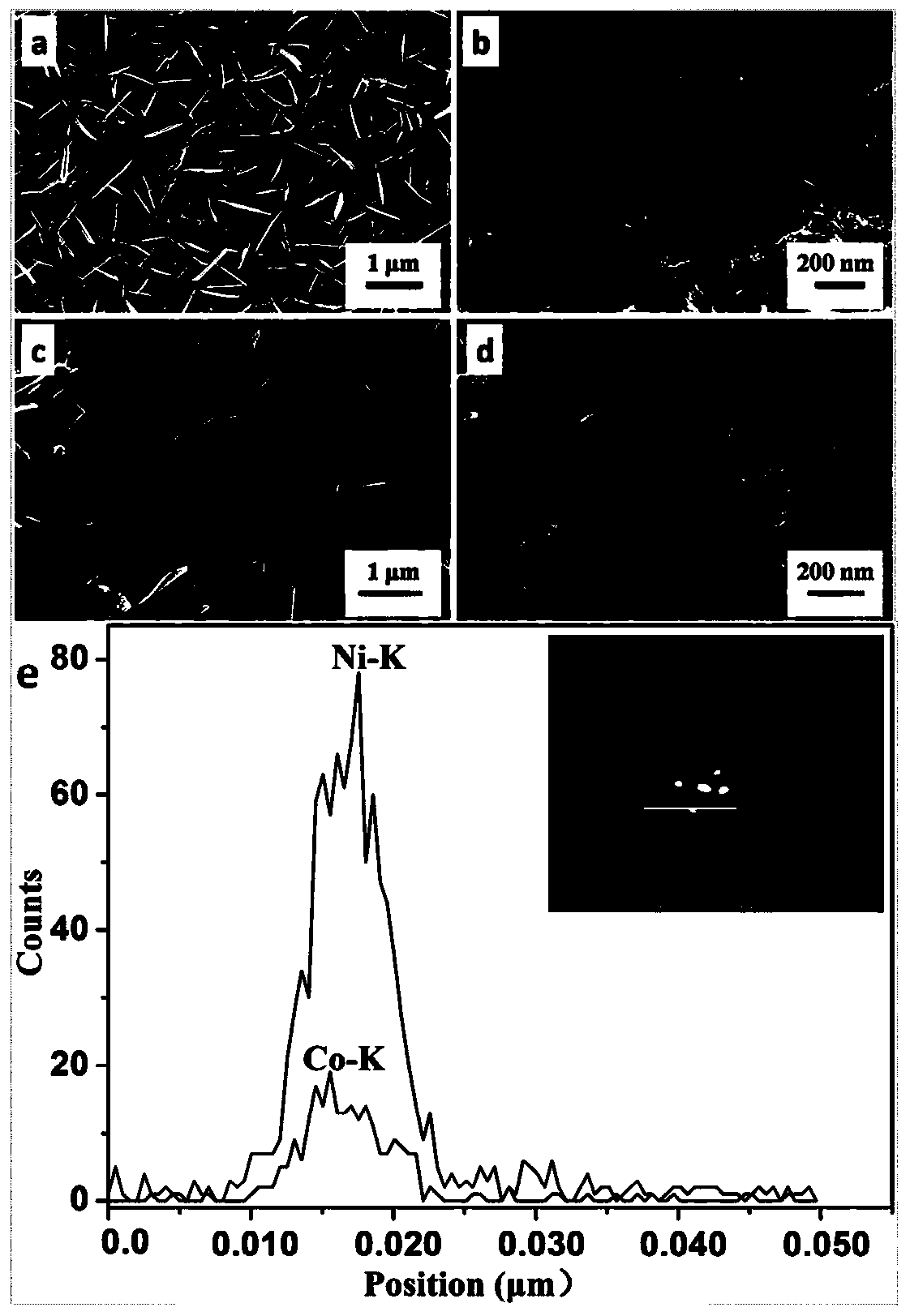

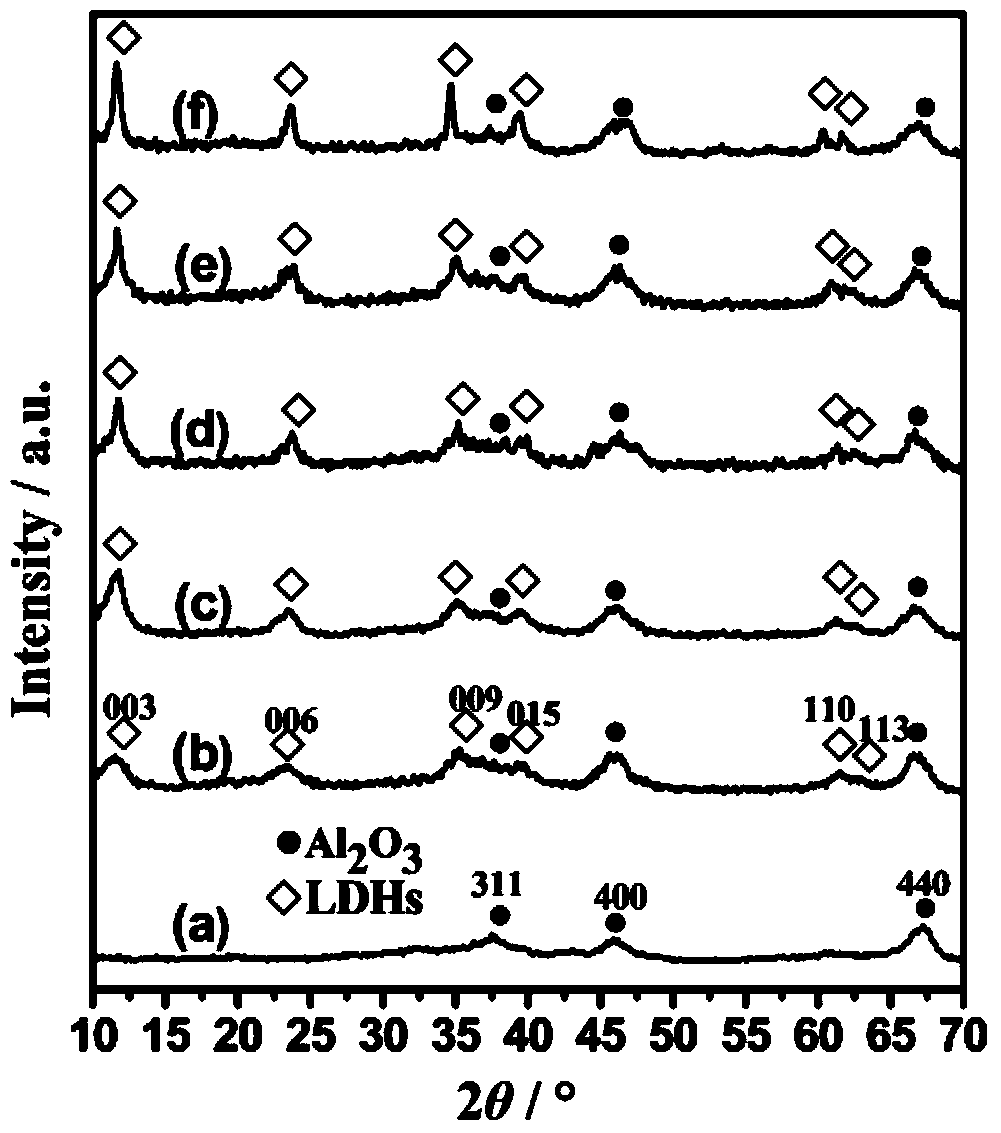

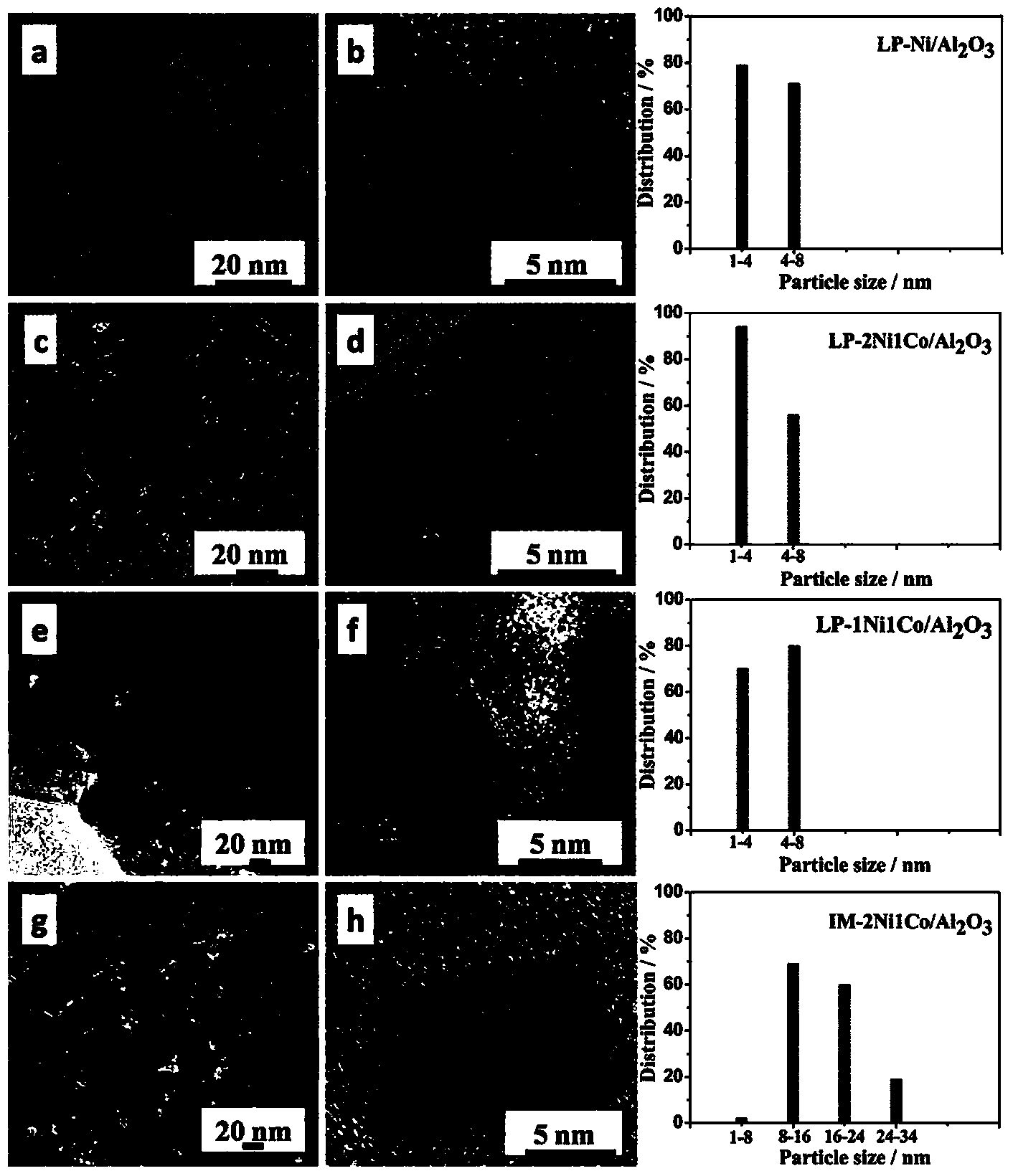

[0022] A. 5g of γ-Al with a particle size of 20-40 mesh 2 o 3 Particles, Ni(NO 3 ) 2 ·6H 2 O, Co(NO 3 ) 2 ·6H 2 O, urea, fast join in 10ml deionized water, Ni and Co total mass fraction are 12wt%, different Ni / Co mass fraction ratio (m / n=3 / 1,2 / 1,1 / 1), urea:( Ni 2+ +Co 2+) was 2:1, vacuum impregnated for 1h, transferred to an autoclave, crystallized at 130°C for 24h, filtered, washed with deionized water until the pH was 7, and the loaded highly dispersed NiCoAl-LDHs were obtained / Al 2 o 3 Precursor (SEM figure and XRD spectrum see figure 1 with figure 2 );

[0023] B. NiCoAl-LDHs / Al 2 o 3 The precursor was dried at 70 °C for 10 h and then calcined at 450 °C for 4 h to obtain LP-NiCoO / Al 2 o 3 ;

[0024] C. The LP-NiCoO / Al prepared in step B 2 o 3 Packed in a miniature fixed-bed reactor, in N 2 Heat treatment at 500°C under protection for 0.5h, with a heating rate of 10°C / min; 2 and N at a flow rate of 30 mL / min 2 The mixed gas is reduced, the reduction...

Embodiment 2

[0043] A. 5g of γ-Al with a particle size of 20-40 mesh 2 o 3 Particles, Ni(NO 3 ) 2 ·6H 2 O, Zn(NO 3 ) 2 ·6H 2 O, urea, fast join in 10ml deionized water, Ni and Zn total mass fraction is 12wt%, different Ni / Zn mass fraction ratio (m / n=3 / 1,2 / 1,1 / 1), urea:( Ni 2+ +Zn 2+ ) was 2:1, vacuum impregnated for 1h, then transferred to an autoclave, crystallized at 130°C for 24h, filtered, washed with deionized water until the pH was 7, and the loaded highly dispersed NiZnAl-LDHs were obtained / Al 2 o 3 precursor;

[0044] B. NiZnAl-LDHs / Al 2 o 3 The precursor was dried at 70 °C for 10 h and then calcined at 450 °C for 4 h to obtain LP-NiZnO / Al 2 o 3 ;

[0045] C. The LP-NiZnO / Al prepared in step B 2 o 3 Packed in a miniature fixed-bed reactor, in N 2 Heat treatment at 500°C under protection for 0.5h, with a heating rate of 10°C / min; 2 and N at a flow rate of 30 mL / min 2 The mixed gas is reduced, the reduction temperature is 500°C, the reduction time is 3h, and the...

Embodiment 3

[0047] A. 5g of γ-Al with a particle size of 20-40 mesh 2 o 3 Particles, Ni(NO 3 ) 2 ·6H 2 O, Cu(NO 3 ) 2 ·3H 2 O, urea, fast join in 10ml deionized water, Ni and Cu total mass fraction are 12wt%, different Ni / Cu mass fraction ratio (m / n=3 / 1,2 / 1,1 / 1), urea:( Ni 2+ +Cu 2+) was 2:1, vacuum impregnated for 1h, then transferred to an autoclave, crystallized at 130°C for 24h, filtered, washed with deionized water until the pH was 7, and the loaded highly dispersed NiCuAl-LDHs were obtained / Al 2 o 3 precursor;

[0048] B. NiCuAl-LDHs / Al 2 o 3 The precursor was dried at 70 °C for 10 h and then calcined at 450 °C for 4 h to obtain LP-NiCuO / Al 2 o 3 ;

[0049] C. The LP-NiCuO / Al prepared in step B 2 o 3 Packed in a miniature fixed-bed reactor, in N 2 Heat treatment at 500°C under protection for 0.5h, with a heating rate of 10°C / min; 2 and N at a flow rate of 30 mL / min 2 The mixed gas is reduced, the reduction temperature is 500°C, the reduction time is 3h, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com